Fire grate suitable for large particle solid fuels

A solid fuel, large particle technology, applied in the directions of furnace grate, combustion method, combustion equipment, etc., can solve the problems of affecting the normal operation of the burner, increasing the manufacturing cost of the burner, prone to failure, etc., and achieves a simple structure and low manufacturing cost. , to ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

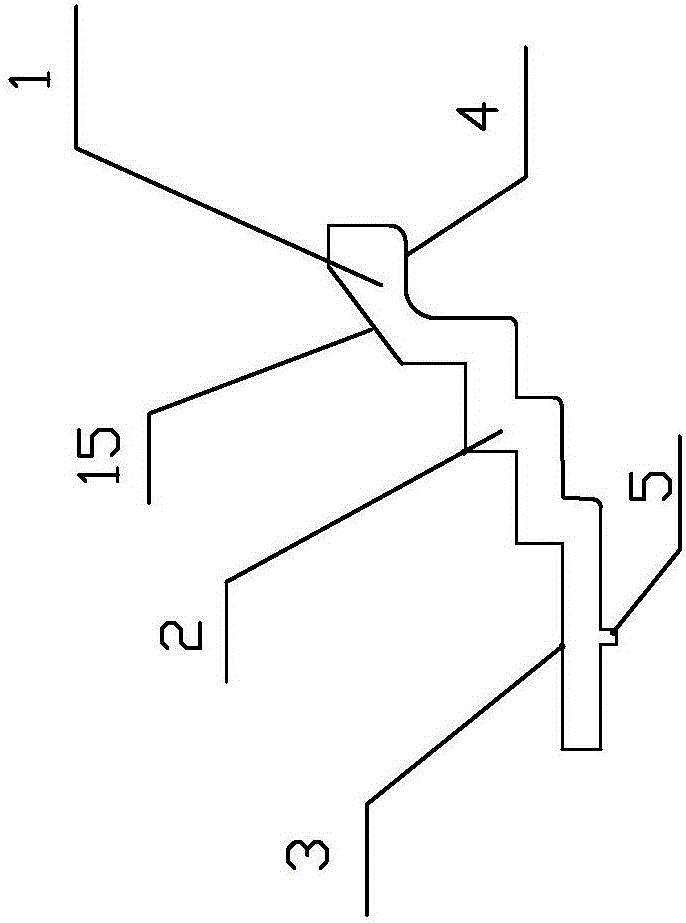

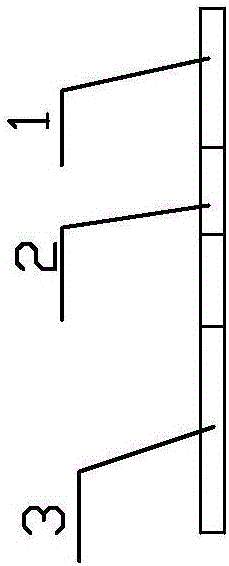

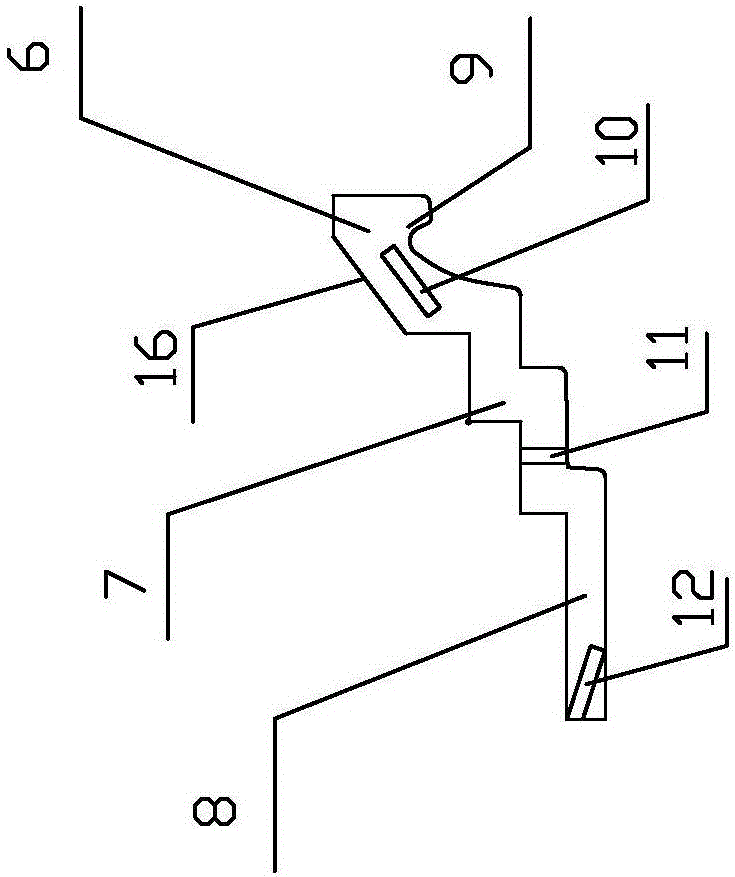

[0028] The present invention is applicable to the schematic diagram of the fire grate of large particle solid fuel as figure 1 Shown, be made up of stepped fixed fire bar 14 and stepped movable fire bar 13. The schematic diagram of the stepped fixed furnace bar is as Figure 2-Figure 3 As shown, it includes the grate base, which is composed of the first fuel drop-off zone 1 on the upper part, the first main fuel combustion zone 2 on the middle part and the first slagging zone 3 on the lower part, and the first fuel drop-off zone The upper end surface 15 of 1 is an inclined surface, and a rocking support surface 4 is provided under the first fuel sliding area 1 . The first fuel main combustion zone 2 is stepped; the upper end surface of the first slagging zone 3 is plane. The schematic diagram of the stepped movable furnace bar is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com