An inner anchor head for down-the-hole impact bottom expansion and its use method

An inner anchor head and submerged hole technology, which is applied in the direction of earthwork drilling, installation of anchor rods, sheet pile walls, etc., can solve the problems of narrow application range, low grinding and reaming, etc., and achieve good reaming effect and low environmental requirements , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

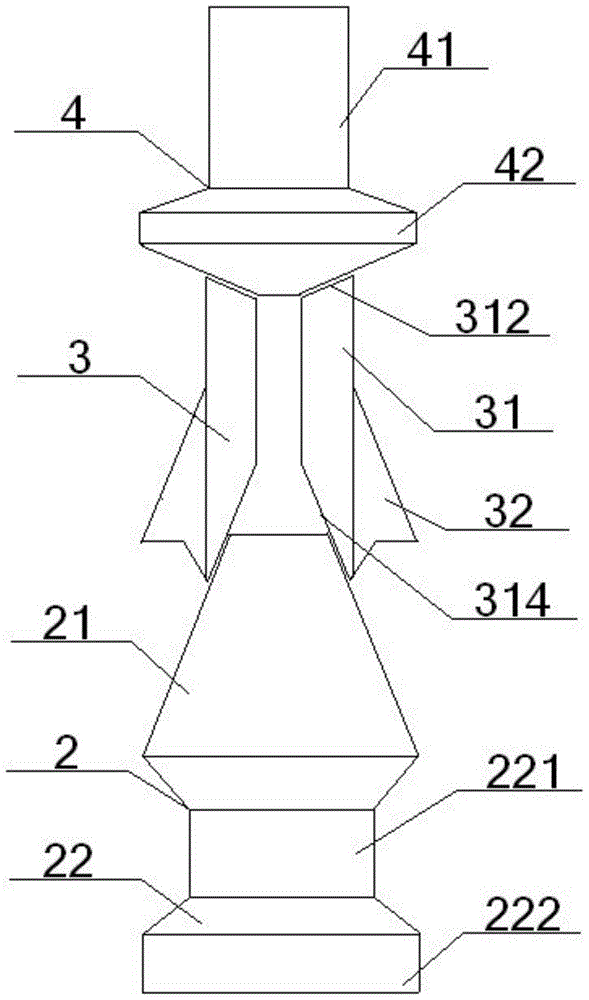

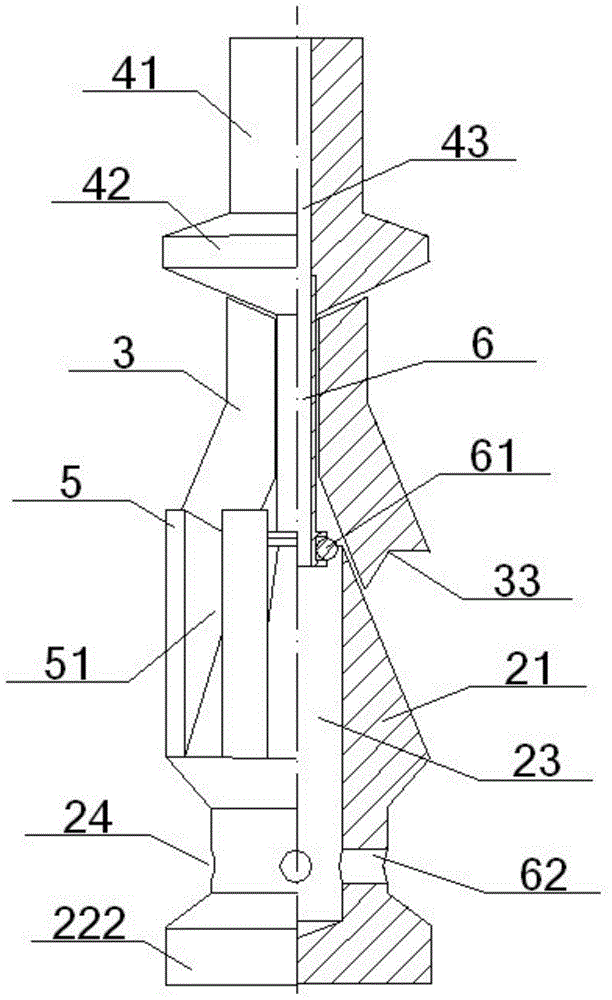

[0061] See figure 1 - Image 6 , A DTH impact expanding bottom inner anchor head, comprising a base 2, a cutter head 3 and a connecting cap 4. The number of the base 2, the connecting cap 4 is one, the number of the cutter head 3 is at least two, and the connecting cap 4. The cutter head 3 and the base 2 are arranged from top to bottom;

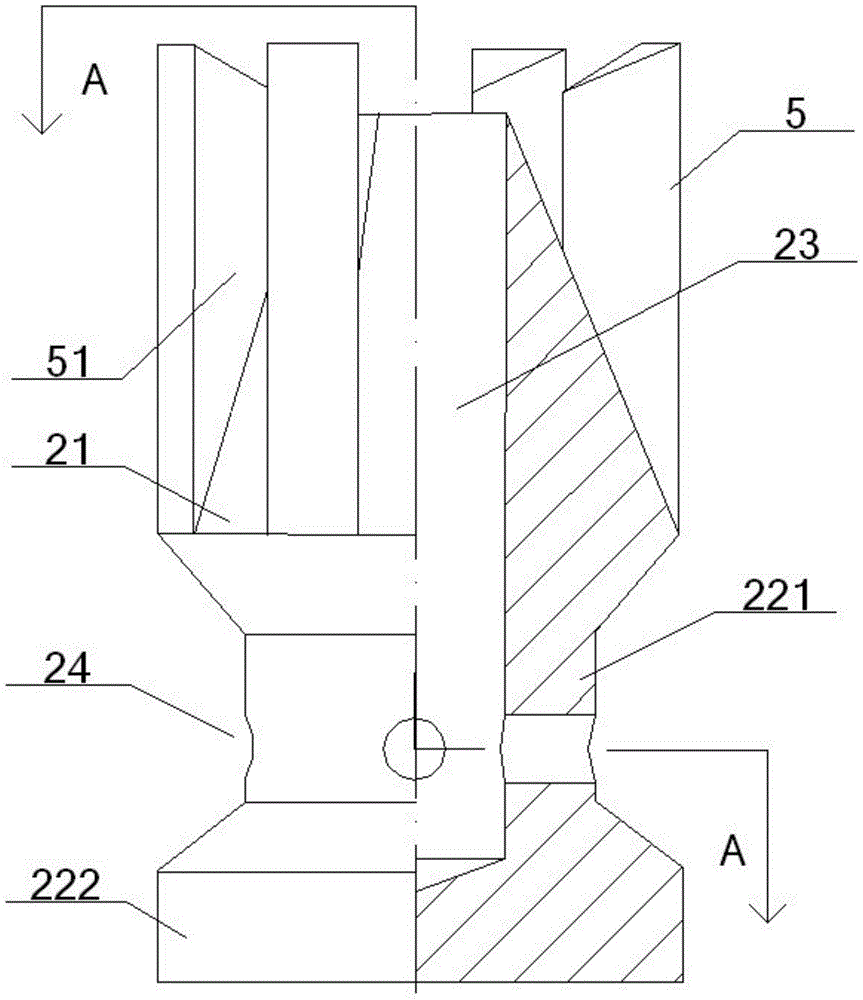

[0062] The base 2 includes a base head 21 and a base tail 22. The base head 21 is a truncated cone structure with a narrow top and a wide bottom. The side surface of the base head 21 is a conical surface or a rhombus cone. The base tail 22 includes The upper tail part 221 and the lower tail part 222, the bottom surface of the base head 21 is connected to the lower tail part 222 after the upper tail part 221, the base head 21 and the upper tail part 221 are provided with the same column-shaped socket 23, the socket The top surface of the base 23 is flush with the top surface of the base head 21, the inner wall of the socket 23 is threaded to conn...

Embodiment 2

[0067] The basic content is the same as Example 1, the difference is:

[0068] A plurality of vertical groove blocks 5 are provided on the side of the base head 21, and a sliding groove 51 corresponding to the cutter head 3 is formed between the adjacent groove blocks 5. The number of the sliding groove 51 and the cutter head 3 is Consistent, the sliding groove 51 is slidingly fitted with the cutter head 3 embedded therein, and the bottom surface of the sliding groove 51 is slidingly fitted with the sliding surface 314 of the cutter head 3 corresponding to the sliding groove 51; the cutter head 3 and the sliding groove 51 The number is 2-18, and the slope of the bottom surface of the chute 51 is 1:1-10:1. The bottom surface of the sliding groove 51 refers to a part of the side surface of the base head 21 in the sliding groove 51. The sliding groove 51 can better position the position of the cutter head 3 during use, and prevent the cutter head 3 from turning over when the connec...

Embodiment 3

[0070] The basic content is the same as Example 1, the difference is:

[0071] The outer corner block 32 is provided with a recessed groove 33 at the junction of the outer plane 313 and the seat sliding surface 314. The groove 33 and the outer corner block 32 form a vertical acute angle 331 and a horizontal acute angle 332. The acute angle 331 is set near the junction of the outer plane 313 and the seat sliding surface 314, and the distance between the horizontal acute angle 332 and the outer plane 313 is the maximum distance between the outer corner block 32 and the outer plane 313.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com