Automatic deslagging latex separator

An automatic slag discharge and separator technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of low production efficiency and large manpower, improve production efficiency, prolong service time, and avoid feeding The effect of channel blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

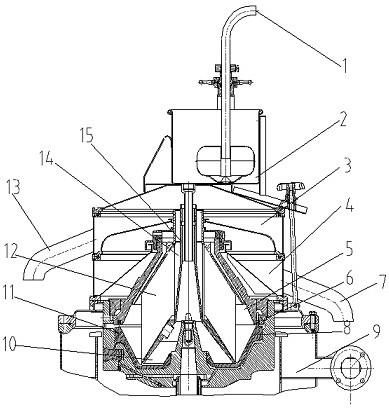

[0016] see figure 1 , the present embodiment provides a kind of automatic slag discharge latex separator, the top of the separator casing is equipped with a feed barrel 2, the pipeline of the feed barrel 2 is inserted into the center of the distributor 15 inside the drum, and the feed barrel 2 is provided with an inlet The feed pipe, the end of the feed pipe extending out of the barrel is connected to the natural fresh latex inlet 1, the disc 12 is sleeved on the rotating shaft of the drum, and the circumference of the disc 12 is provided with a heavy liquid channel 15, and the circumference of the distributor 15 The clear liquid channel 14 is set outward, and the upper cover 3 and the lower cover 4 are installed in the separation casing. The upper cover 3 is connected with the concentrated latex outlet 13 through the pipeline, and the lower cover 4 is connected with the latex outlet 7 through the pipeline, and the weight is relatively light. The concentrated natural rubber la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com