Internal rotary gasifier and domestic waste treatment technology

A technology for domestic garbage and gasification furnaces, which is applied in the direction of gasification device feeding tools, petroleum industry, and the manufacture of combustible gases, etc. It can solve problems such as pollution, achieve high efficiency, realize energy recycling, and achieve good gasification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

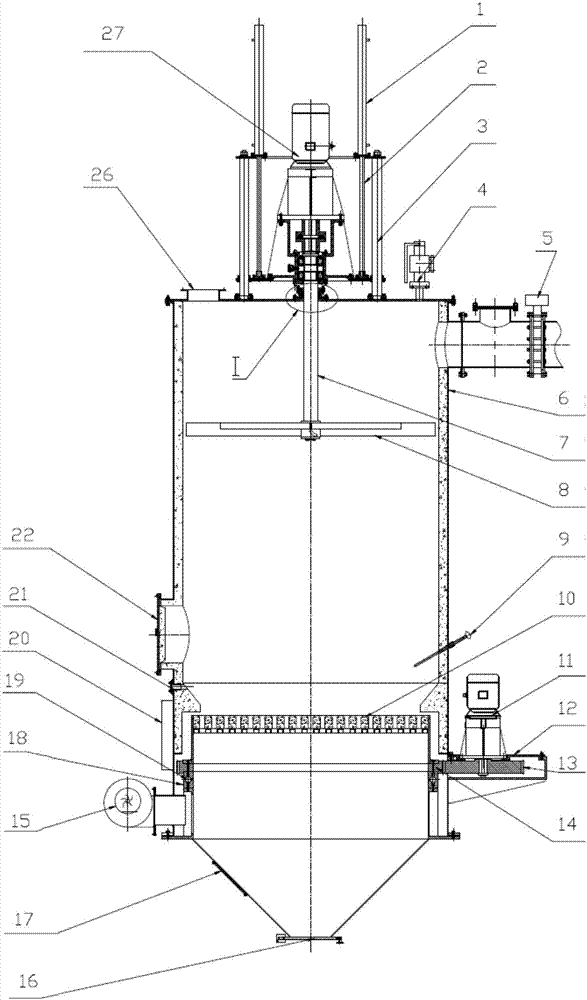

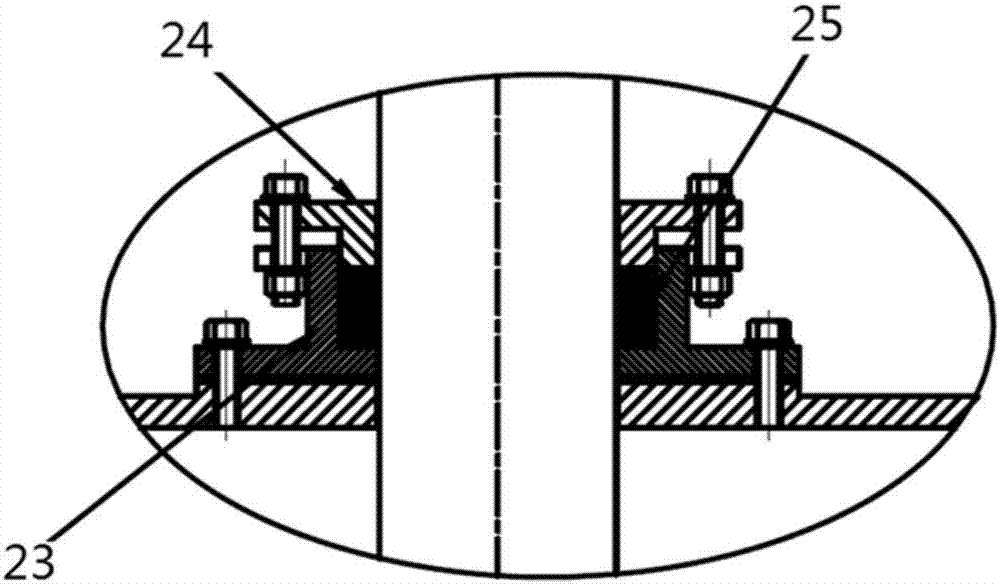

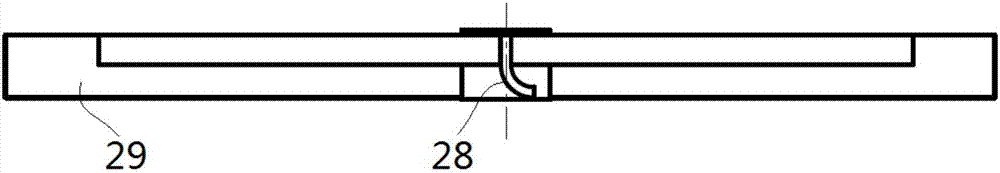

[0034] An internal rotary gasifier, such as figure 1 As shown, it includes a furnace body, a leveling and pressing structure, a furnace bridge, a lifting device and a rotating device for driving the leveling and pressing structure to lift and rotate, and a furnace bridge rotating device for driving the furnace bridge to rotate.

[0035] The rotating device is mainly composed of a motor and a reducer 27, and the motor is connected to the top of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com