Juicer

A juicer and juice extraction technology, which is applied in the direction of household machinery for filtering food, household appliances, applications, etc., can solve the problems of automatic slag discharge, etc., and achieve the effect of convenient operation and avoiding uncleanness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

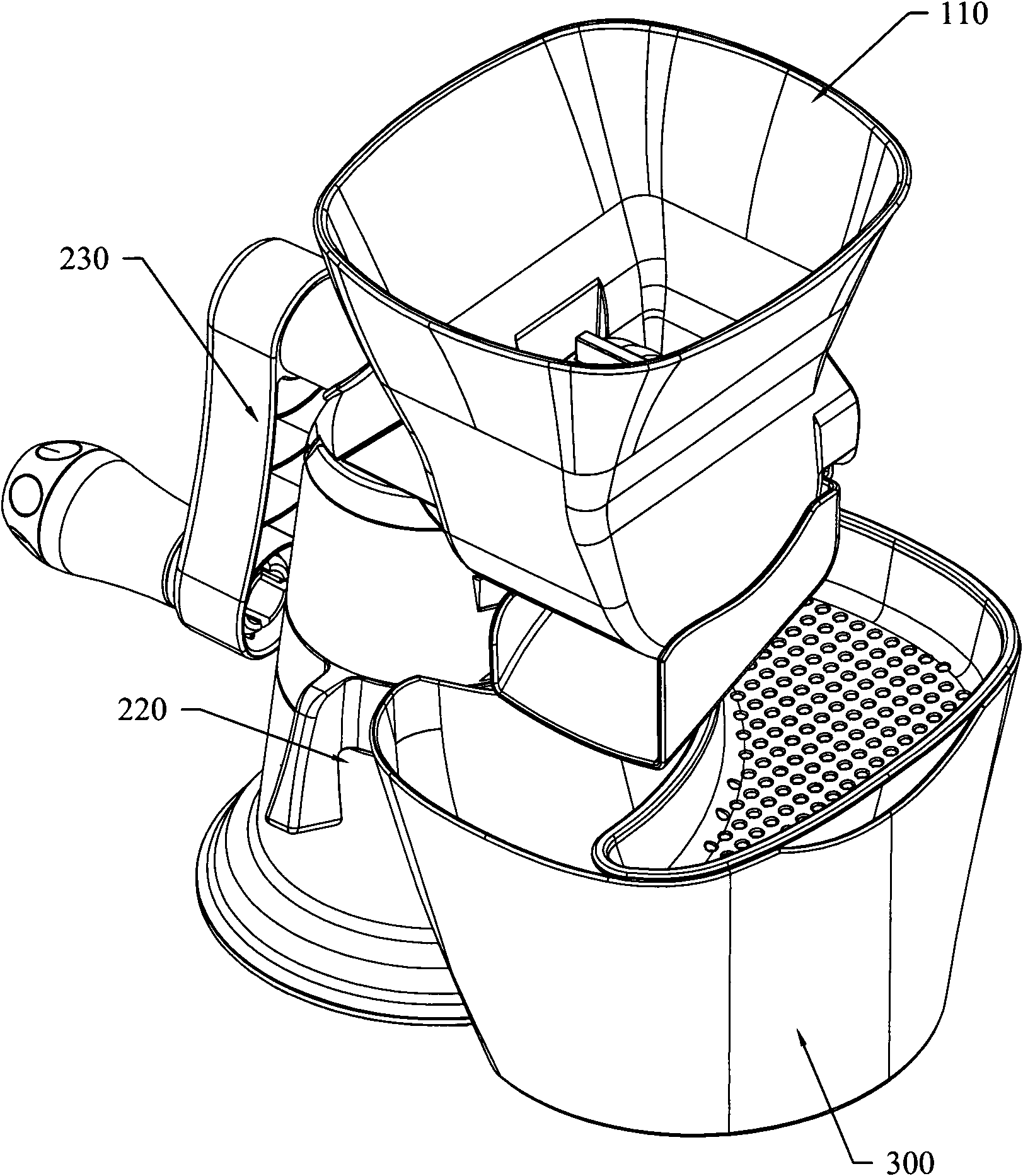

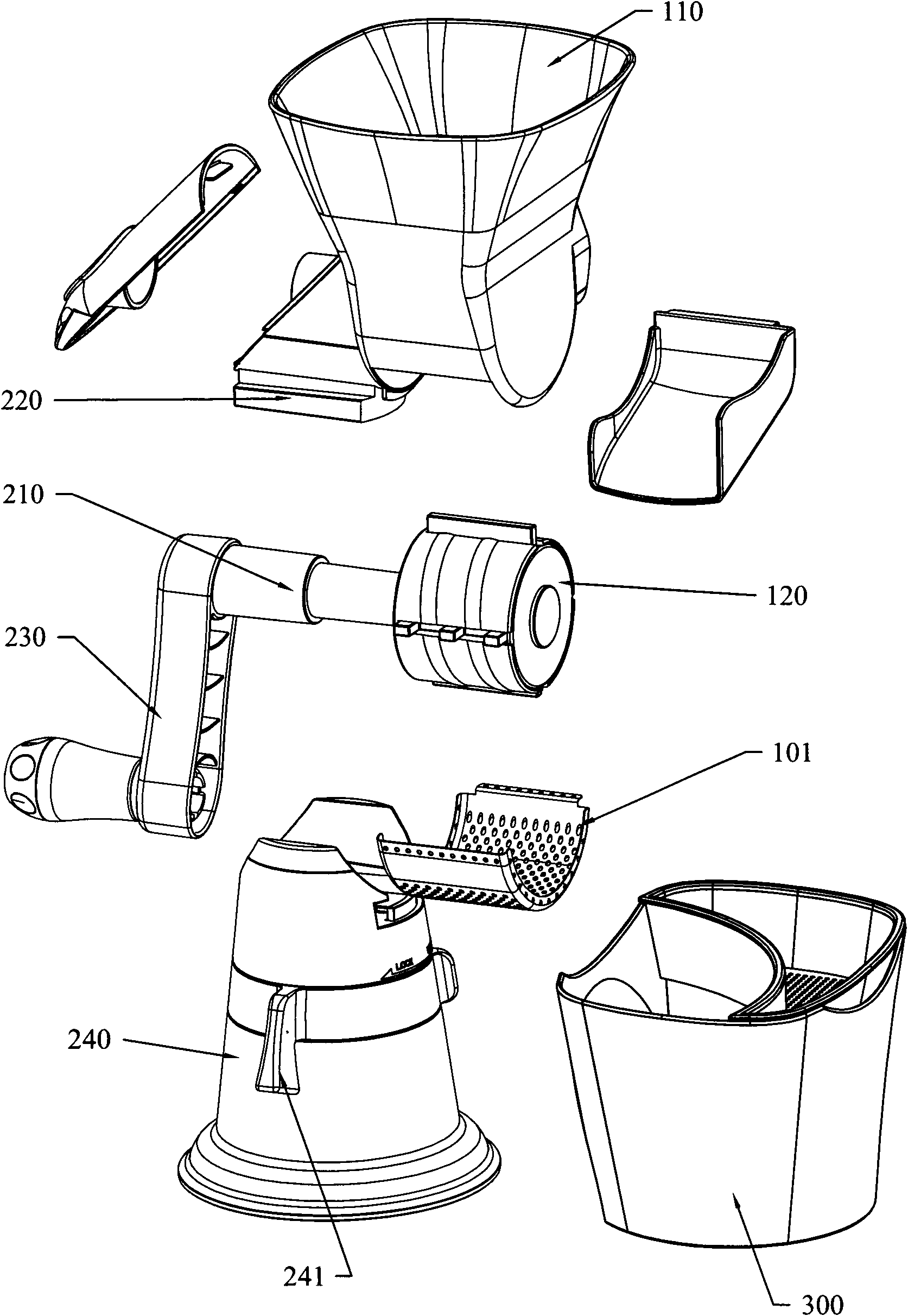

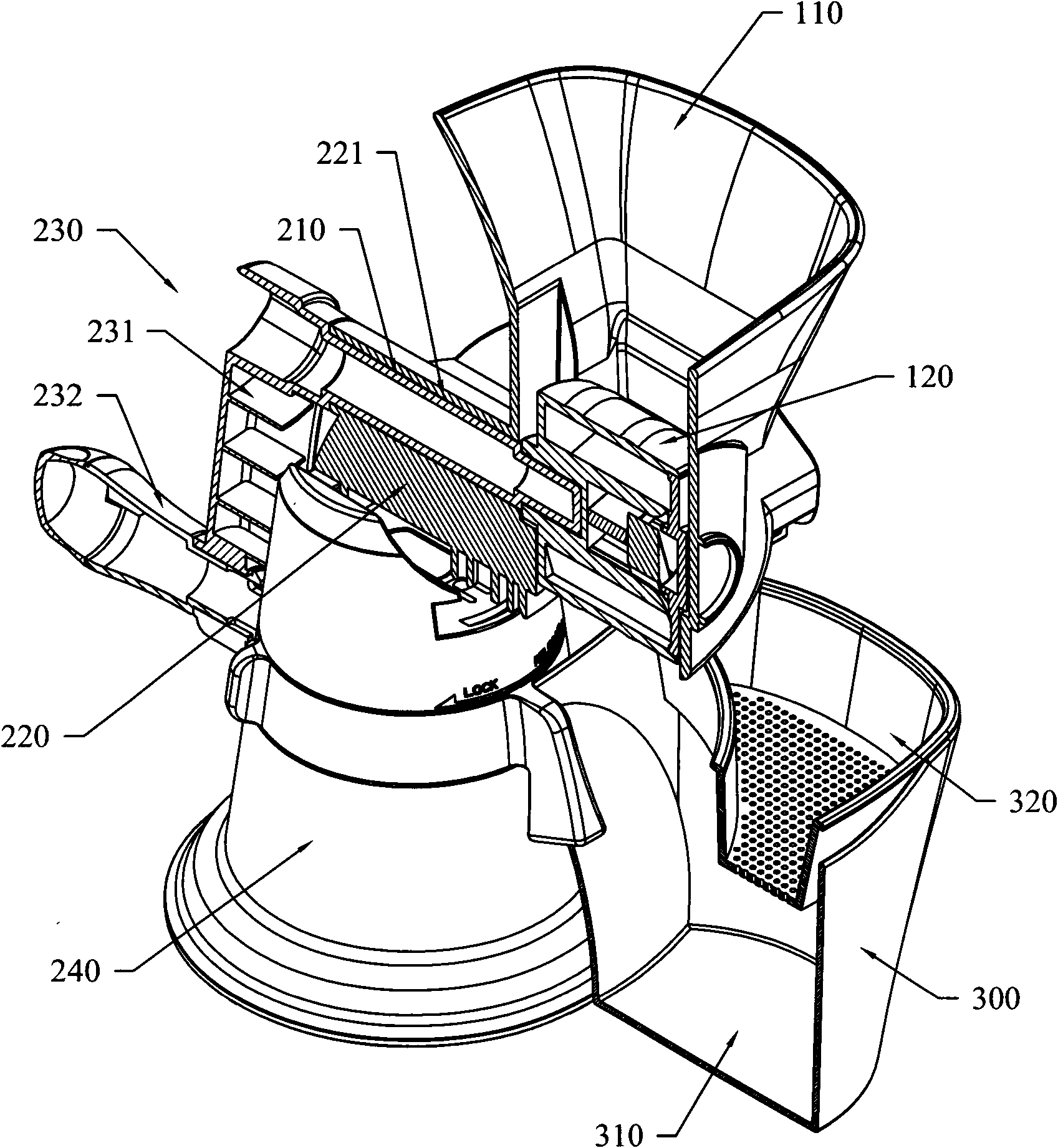

[0035] The juice extractor of the present invention comprises a juice extraction mechanism and a drive mechanism for driving the juice extraction mechanism to operate, wherein the juice extraction mechanism includes a container 110, a drum 120 that is rotatably arranged in the container 110 and driven by the drive mechanism; A scraper for the pressing surface; a juice outlet 111 and a slag outlet 112 are respectively provided on the container wall. The roller 120 rolls and cooperates with the container wall to squeeze the fruit or vegetable, thereby breaking the fruit capsule to form fruit juice or vegetable juice, the fruit juice or vegetable juice flows out from the juice outlet 111, and the pomace or vegetable residue is discharged from the slag outlet 112, In this way, automatic slag discharge is realized without manual slag discharge, and the operation is more convenient and clean.

[0036] Specifically, such as figure 1 , 2 , 3, and 4, in a preferred embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com