Fire coal smoke cyclone dedusting desulfurizer

A desulfurization device and coal-fired flue gas technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of coal-fired boiler flue gas emissions, achieve low operating costs, and eliminate secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

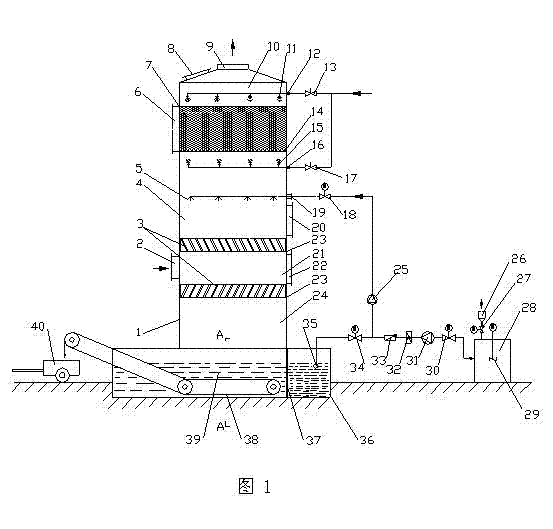

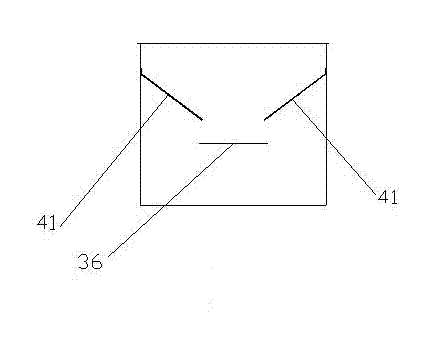

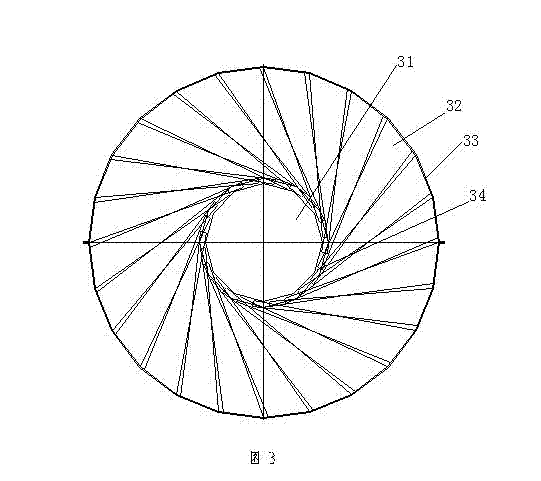

[0012] see figure 1 ~8, the present invention is provided with body 1, smoke inlet 2, swirl disc 3, desulfurization chamber 4, lye sprayer 5, working ports 6, 8, 20, 22, activated carbon desulfurization ring 7, smoke outlet 9 , clean room 10, water sprayer 11, 15, water inlet 12, 16, gate valve 13, 17, shelf 14, solenoid valve 18, 27, 30, 34, lye inlet 19, first dust removal chamber 21, Support 23, second dust removal chamber 24, solution mixing pump 25, alkali adding bucket 26, circulating alkali tank 28, agitator 29, solution delivery pump 31, electric disc valve 32, check valve 33, liquid level switch 35, filter Pool 36, filter plate 37, slag scraper 38, water bath dedusting room 39, transfer vehicle 40 and deflector 41.

[0013] The flue gas enters the first dust removal chamber 21 from the flue inlet 2. When the dust-laden flue gas enters the swirling disk, an inertial swirl flow is generated, and the dust sinks by gravity. , into the desulfurization chamber 4, the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com