A forward and reverse double circulation water pump

A dual-circulation, water pump technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problem that the water pump cannot achieve dual-circulation, etc., and achieve the effects of easy connection, prolonged use time, and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

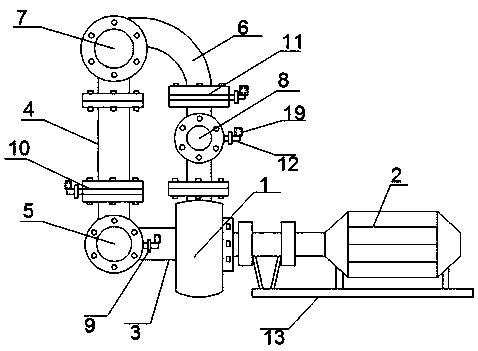

[0029] A forward and reverse double circulation water pump, comprising a water pump body 1, a water inlet is opened on the left side of the water pump body 1, a water outlet is opened on the top, a first connecting pipe 3 is arranged on the water inlet, and a first connecting pipe 3 is arranged on the upper surface The second connecting pipe 4 communicated with the first connecting pipe 3, the first connecting pipe 3 is also provided with a liquid inlet pipe 5 perpendicular to the second connecting pipe 4, one end of the third connecting pipe 6 communicates with the second connecting pipe 4, The other end is set at the water outlet of the water pump body 1,

[0030] The connection between the second connecting pipe 4 and the third connecting pipe 6 is provided with a first liquid outlet pipe 7, the middle part of the third connecting pipe 6 is provided with a second liquid outlet pipe 8, the liquid inlet pipe 5, the second connecting pipe 4, the third The connecting pipe 6 and...

Embodiment 2

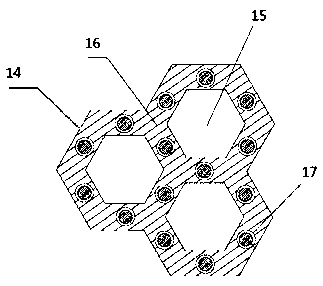

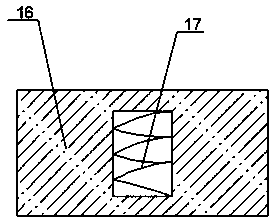

[0034] On the basis of Embodiment 1, the water pump body 1 is connected to the motor 2, and a shock absorber 13 is arranged at the lower part of the motor 2. The shock absorber 13 includes a shock absorber body 14, and the shock absorber body 14 is provided with a penetrating shock absorber body 14. Hole 15, hole wall 16 is formed between adjacent hole 15, the inside of hole wall 16 is embedded with spring 17, and the setting direction of spring 17 is perpendicular to the upper surface of shock-absorbing pad body 14, and the length of spring 17 is less than shock-absorbing pad The thickness of the main body 14 reduces the vibration received by the motor 2 and prolongs the service time.

Embodiment 3

[0036] On the basis of the embodiment 1-2, the upper surface and the lower surface of the shock absorbing pad body 14 are provided with patterns, and the patterns are zigzag, which not only has the function of shock absorption, but also can play the role of anti-slip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com