Borehole-blasting method tunnel weak large deformation and rock burst pretreatment TBM (Full Face Rock Tunnel Boring Machine)

A technology of large deformation and drilling and blasting, which is applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problems of low construction efficiency and safety factor, and achieve the effect of reducing construction risk, improving construction efficiency, and improving construction safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

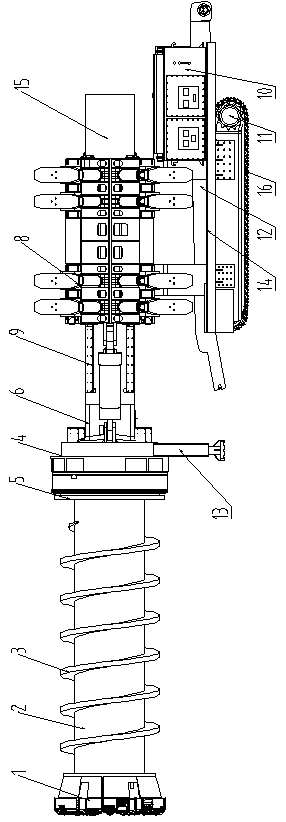

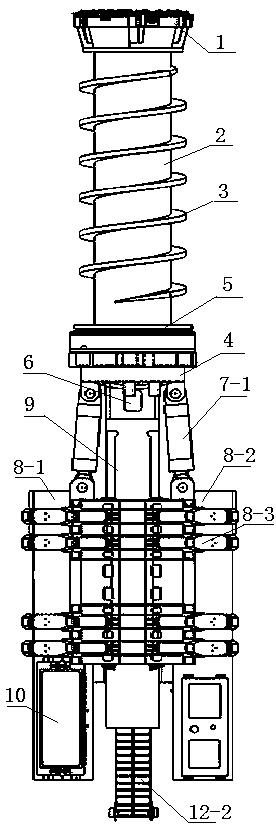

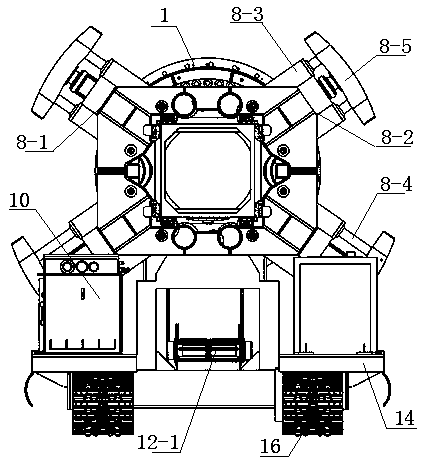

[0023] Embodiment 2, a kind of drilling and blasting method tunnel weak large deformation and rockburst pretreatment TBM, said propulsion mechanism 7 includes symmetrically arranged propulsion cylinders 7-1, one end of one propulsion cylinder 7-1 is hinged to the main drive 4, The other end is hinged with the corresponding left bracket 8-1. One end of another propulsion oil cylinder 7-1 is hinged with the main drive 4, and the other end is hinged with the corresponding right bracket 8-2. Under the action of the propulsion cylinder, the main drive drives the inner casing to move along the outer casing to realize the expansion and contraction of the cutterhead to complete an excavation stroke.

[0024] Further, the output end of the main drive 4 is provided with a main bearing 5, the hollow shaft 2 cooperates with the main bearing 5, and the main drive drives the hollow shaft to rotate to realize the rotation of the cutter head. The bottom of the main drive 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com