Method for construction of underground continuous steel jacket box

A technology of underground diaphragm wall and construction method, which is applied in the direction of excavation, artificial island, sheet pile wall, etc., can solve problems such as inability to meet requirements, and achieve the effects of convenient installation in time, reduced impact, and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The construction method of the present invention can start from the construction method pile sealing wall to carry out the continuous wall steel box construction in one direction, and can also start from the middle groove section to construct on both sides in turn. The following is combined with the accompanying drawings to start the continuous wall steel box from the middle. Construction is taken as an example to further illustrate the specific implementation of the present invention.

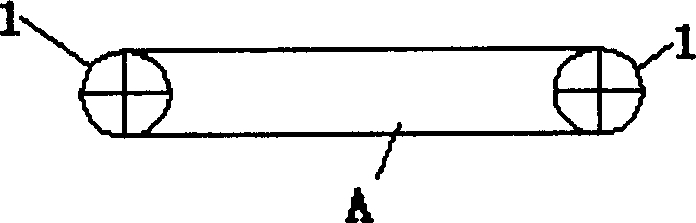

[0020] (1) if figure 1 As shown, at first the first auxiliary groove section A is grooved, the hole is cleared, the steel cage is lowered, the first locking pipe 1 is lowered, and concrete is poured;

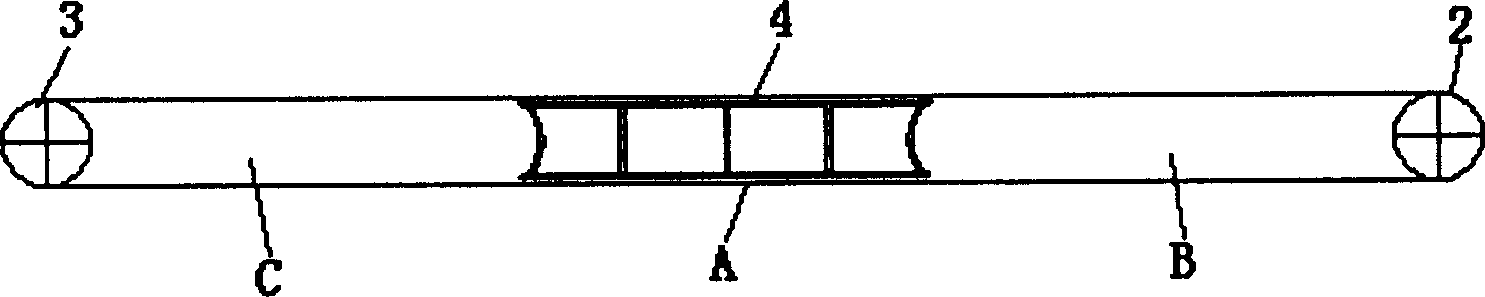

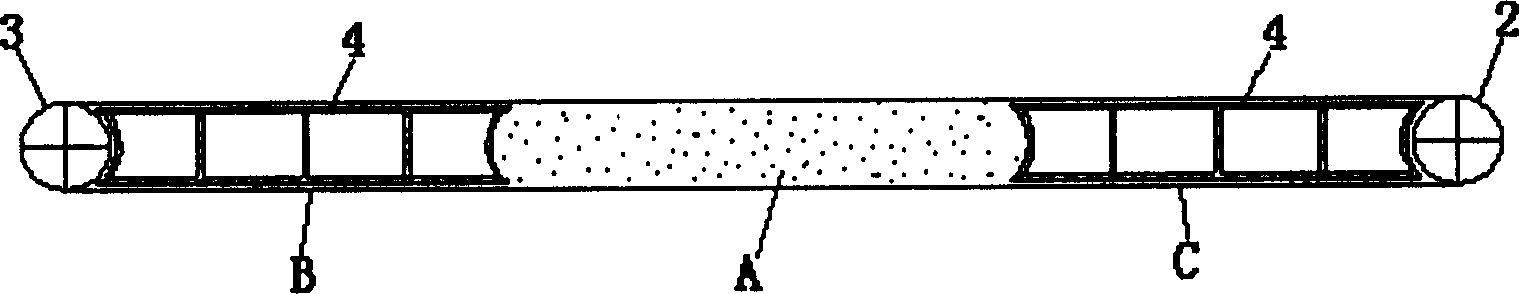

[0021] (2), such as figure 2 As shown, when the concrete is initially set, the first lock pipe 1 is pulled out, and the steel sleeve box 4 is inserted into the first auxiliary groove section A;

[0022] (3), such as figure 2 As shown, the second auxiliary groove section B adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com