Marine serial-wash filter

A technology for cleaning filters and filters, which is applied in the field of marine string washing filters, which can solve the problems of poor string washing effect, low temperature of string washing oil, and increased cost, and achieve the effects of easy observation, improved string washing efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

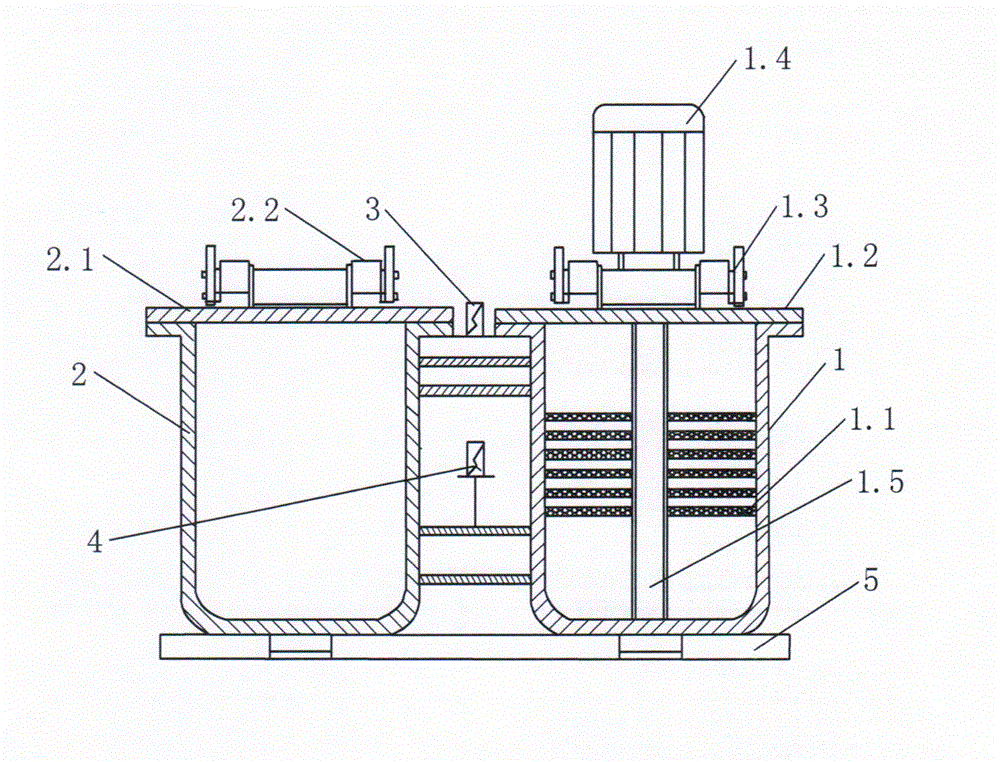

[0009] As shown in the figure, a serial washing filter 1 and a filter paper filter 2 are respectively placed on the heating base plate 5;

[0010] The string washing filter is a pot-shaped structure, the upper part is provided with a string washing filter cover 1.2, a string washing filter pressure difference indicator 1.3 is installed on the string washing filter cover, a motor 1.4 is installed on the upper part of the string washing filter, and a rotating shaft connected with the motor 1.5 Interspersed in the middle of the filter element 1.1.

[0011] The filter paper filter is a pot-shaped structure, the upper part is provided with a filter paper filter upper cover 2.1, and a filter paper filter pressure difference display 2.2 is arranged on the filter paper filter upper cover, and filter paper is housed in the filter paper filter.

[0012] A differential pressure automatic switching control valve 3 and a temperature automatic switching control valve 4 are installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com