Array type gas inlet mixing valve

An array type, mixing valve technology, applied in the direction of oil supply device, internal combustion piston engine, engine components, etc., can solve the problems of high cost, insufficient gas combustion, etc., and achieve the effect of low manufacturing cost, simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

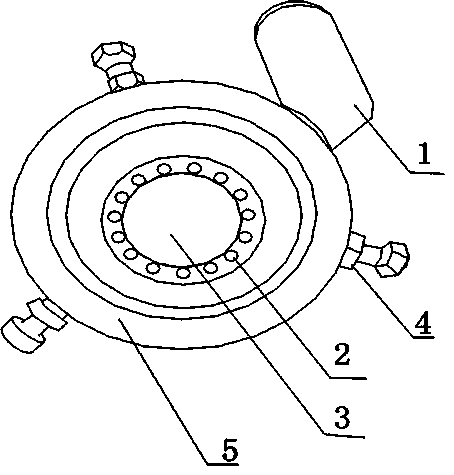

[0019] Such as figure 1 As shown, the circular valve body 5 is fixed on the intake valve by mounting bolts 4; the decompressed natural gas enters the circular valve body 5 through the CNG intake pipe 1, and then is distributed in the air intake port 3 in a circular array The CNG sub-port 2 disperses it evenly and fully mixes it with the air passing through the air intake port 3 to achieve a mass ratio of air and natural gas of about 12:1 (standard state), which solves the problem of insufficient fuel combustion and low reliability The problem.

Embodiment 2

[0021] Such as figure 1 As shown, this embodiment is based on Embodiment 1. As a preference, the material of the circular valve body 5 is Q345R steel plate. It has good comprehensive mechanical properties, process performance and high economic rationality. In addition to higher tensile strength and elongation requirements than Q345 (16Mn) steel, it also guarantees stronger impact toughness.

Embodiment 3

[0023] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, a fastening nut is provided on the mounting bolt 4, and the type of the nut is M6. In order to eliminate the use of bolts for a long time, especially when they are used in high temperature environments, they are bonded with the round valve body. A nut (equivalent to a gasket) is specially added to make the bolt better fasten the round valve body. On the engine intake valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com