After-combustion type low consumption high efficiency smokeless green boiler

A high-efficiency, combustion-type technology, applied in the field of coal-fired boilers, can solve the problems of insufficient coal combustion, low heat utilization rate, and environmental pollution, and achieve the effect of solving insufficient coal combustion, high thermal efficiency, and solving air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

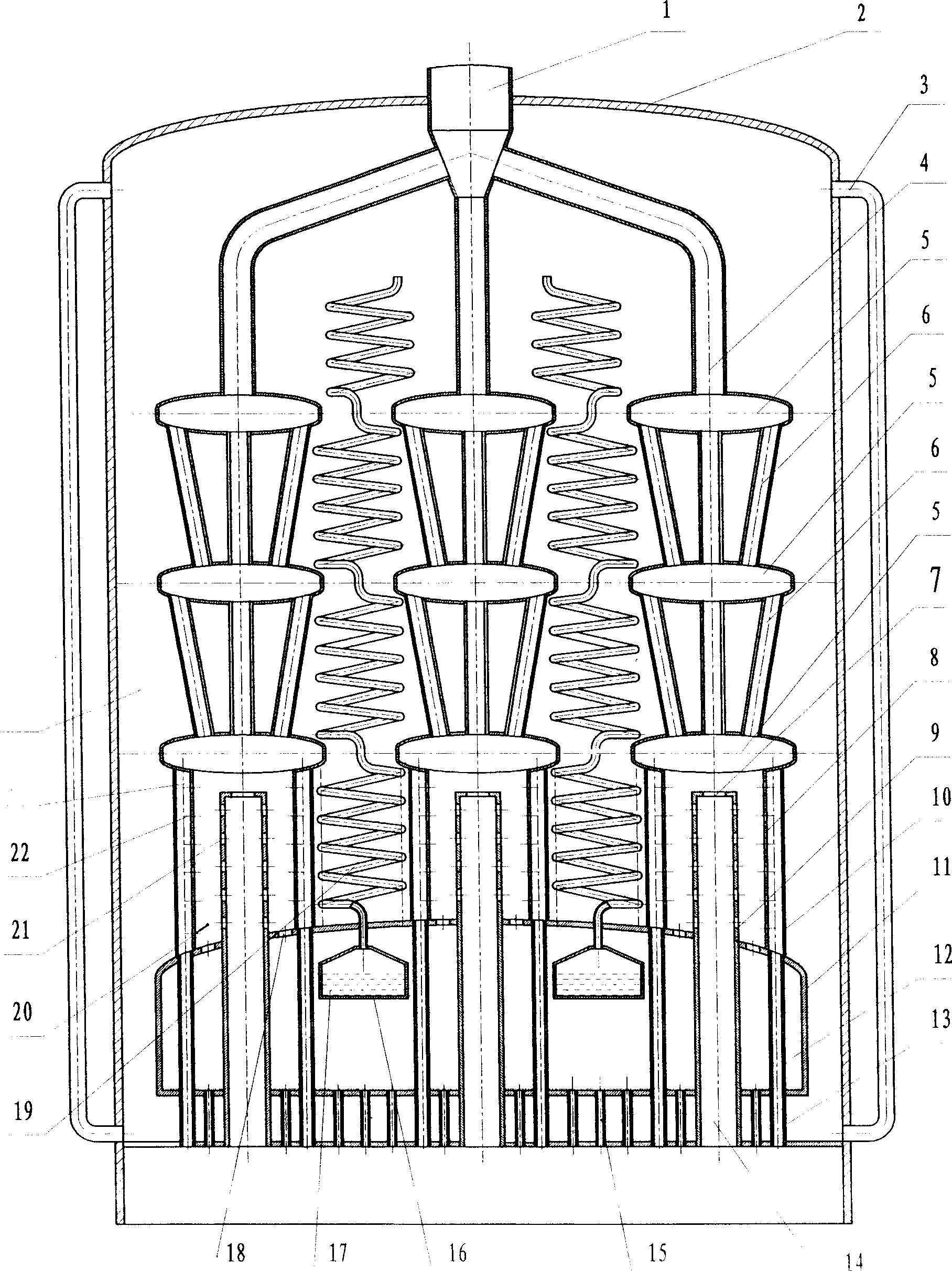

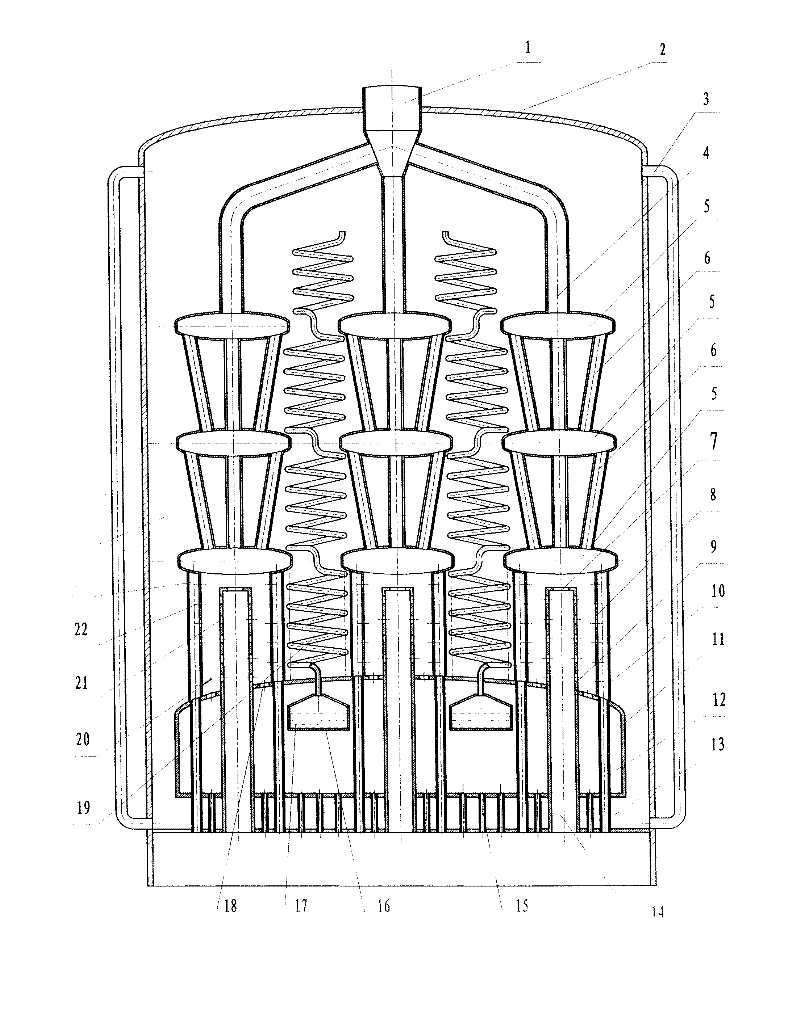

[0010] Taking a one-ton boiler as an example, the drum is welded with a 3.0 mm thick steel plate, with a total height of 1500 mm and a diameter of 1000 mm. The automatic circulation pipe is welded with a seamless galvanized iron pipe with a diameter of 32 mm. The air guide pipe between the bottom of the furnace and the combustion chamber is welded with a seamless steel pipe with a diameter of 25 mm, and its length is 100. There are 200 air guide pipes in total. The combustion chamber is welded with a 5 mm thick iron plate, the combustion chamber is supported by the air duct, and suspended in the drum, and there is one recombustion chamber, and the outer wall of the outer honeycomb cylinder of the recombustion chamber is welded with a 2.0 mm thick iron plate, with a diameter of 150 mm, height 150 mm, the outer honeycomb cylinder is welded with thick 2.0 iron plate, diameter 130 mm, height 150 mm, holes of φ5 mm are evenly distributed on the wall of the cylinder at intervals of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com