Multichannel rotational flow coal burner

A technology of pulverized coal burner and cyclone, which is applied in the direction of burner, burner for burning powder fuel, combustion method, etc. It can solve the problems of insufficient combustion and poor stability of pulverized coal flame, so as to avoid the reduction of secondary air volume Small, to avoid the effect of secondary air volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

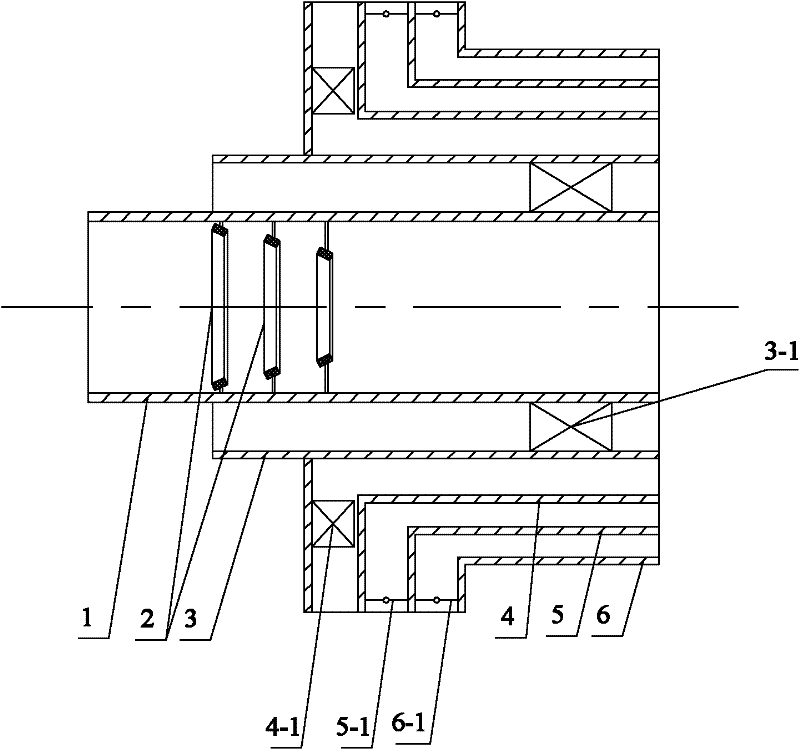

[0012] Specific implementation mode one: as Figure 1~4 As shown, the multi-channel swirl pulverized coal burner of this embodiment includes a primary air duct 1, a first secondary air duct 3, a second secondary air duct 4, a third secondary air duct 5, and a secondary air regulating duct 6 and a plurality of conical separation rings 2 with different diameters, the primary air duct 1 is provided with a plurality of conical separation rings 2 with different diameters, and the plurality of conical separation rings 2 with different diameters are The length direction of the air duct 1 is arranged in order from large to small, and the small end of each conical separation ring 2 is directed towards the outlet end of the primary air duct 1. The swirl pulverized coal burner also includes a first swirler 3- 1. The second cyclone 4-1, the third secondary air duct damper 5-1 and the secondary air regulating duct damper 6-1, one end of the primary air duct 1 is set in the first secondary ...

specific Embodiment approach 2

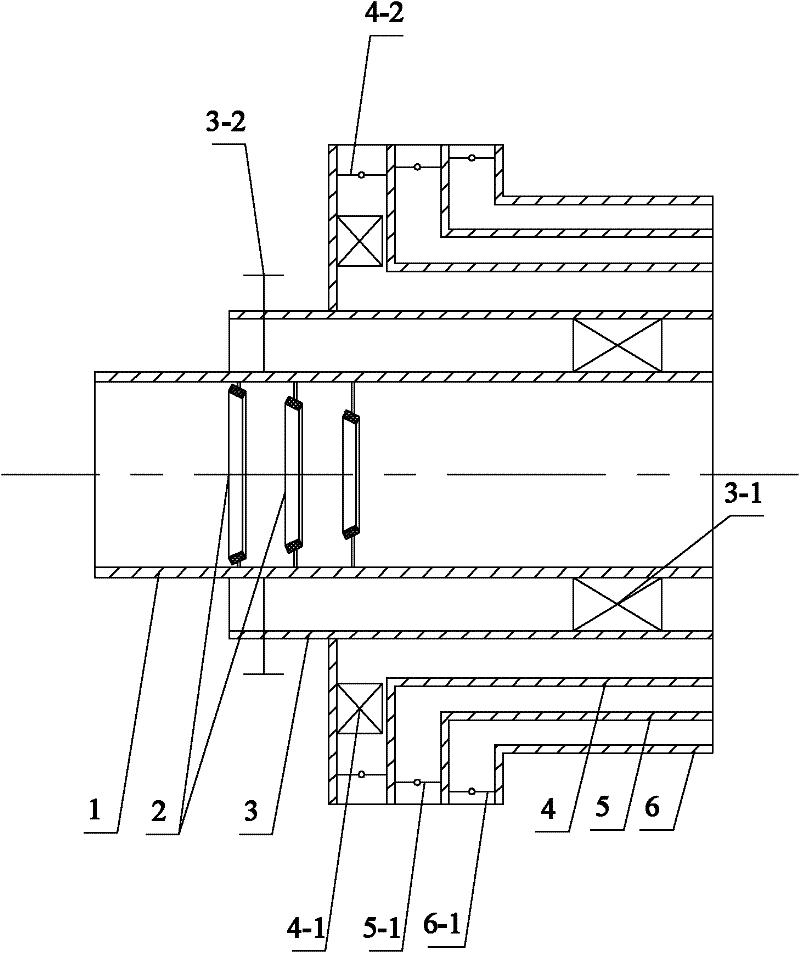

[0013] Specific implementation mode two: as figure 2 As shown, the swirl pulverized coal burner described in this embodiment also includes a first secondary air duct damper 3-2 and a secondary air second duct damper 4-2, and the first secondary air duct damper 3-2 It is arranged in the first secondary air duct 3 , and the second secondary air duct damper 4 - 2 is arranged in the second secondary air duct 4 . With such a design, the independent adjustment of the air volume in the first secondary air duct 3 and the second secondary air duct 4 can be realized, making the operation adjustment of the burner more flexible and convenient when the secondary air volume changes greatly. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

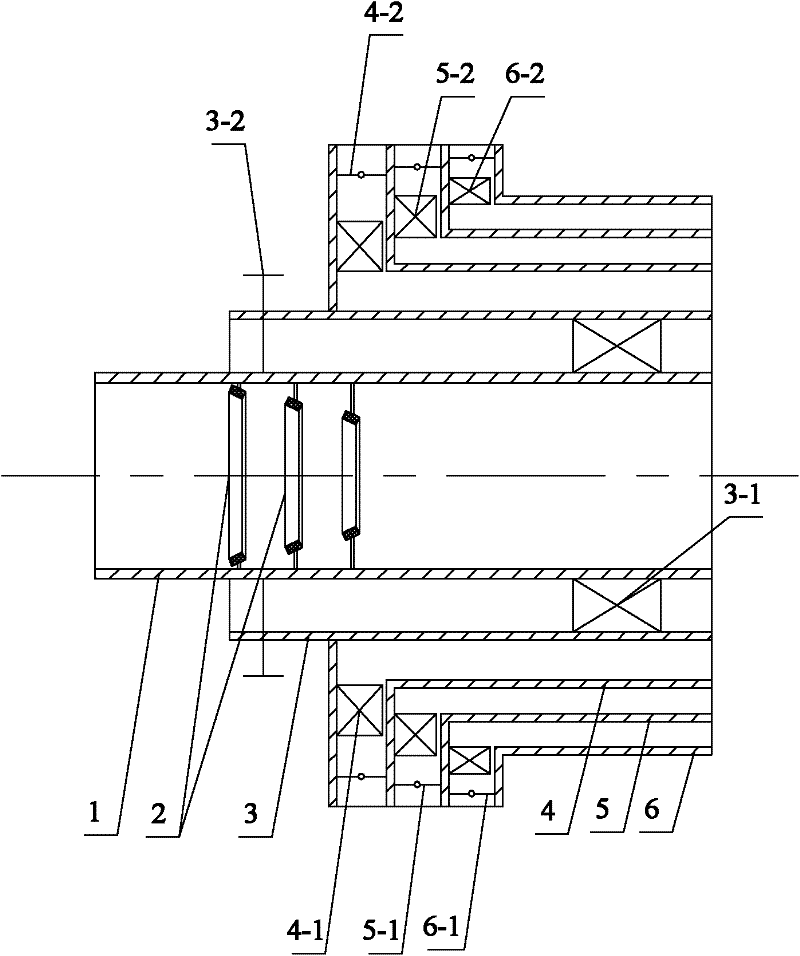

[0014] Specific implementation mode three: as image 3 As shown, the swirl pulverized coal burner in this embodiment also includes a third swirler 5-2 and a fourth swirler 6-2, and the third swirler 5-2 is arranged at the second In the third pipeline 5 , the fourth cyclone 6 - 2 is arranged in the secondary air regulating pipeline 6 . With such a design, the wind in the third secondary air duct 5 and the secondary air regulating duct 6 can form a swirling flow. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com