Method for producing granular fuel from biomass industrial produced wastes

A pellet fuel and waste technology, which is applied in the field of environmental protection and comprehensive utilization of biomass industrial production waste, can solve the problems of high product cost, high technical requirements, complicated process, etc., and achieve the effect of saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

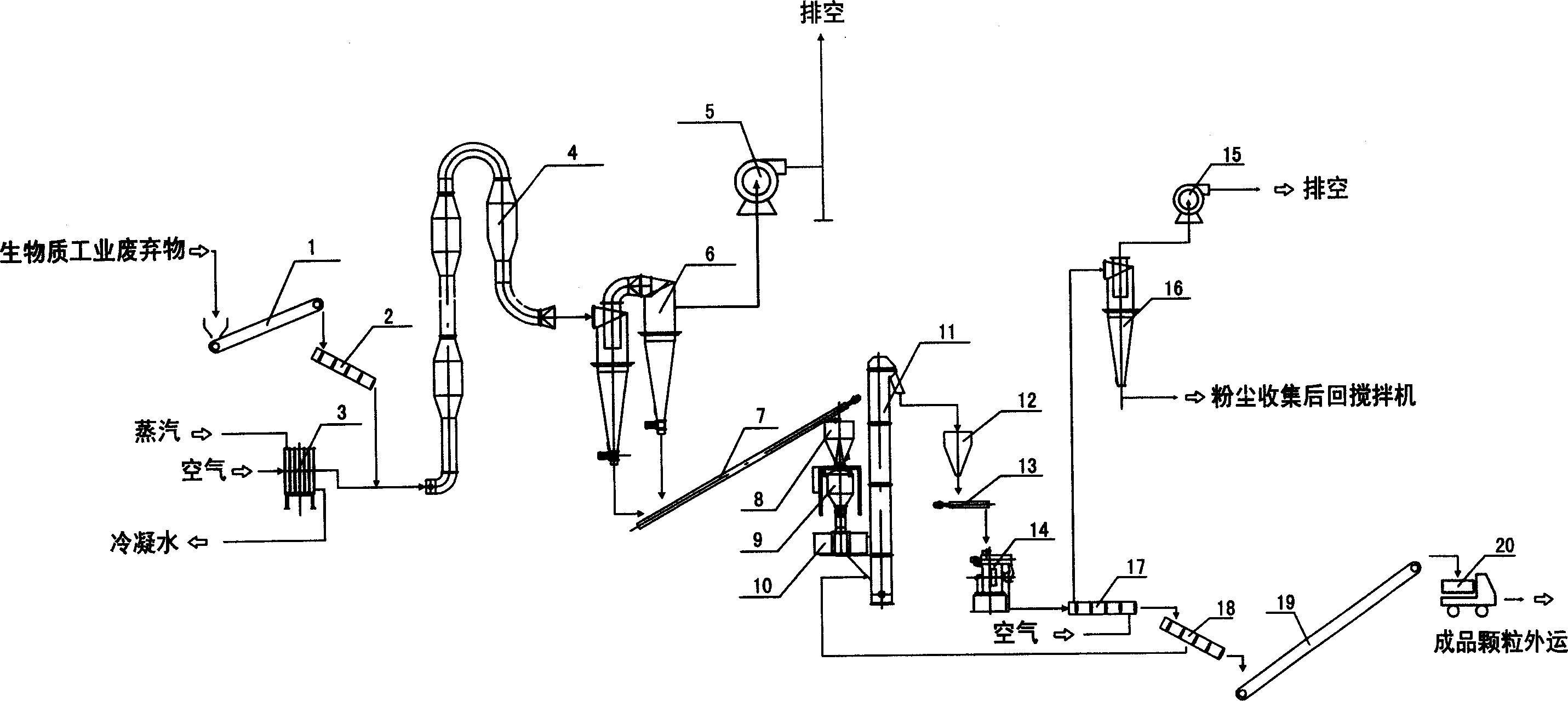

[0015] According to the process flow shown in the attached figure, the drying, granulation, cooling, screening and other systems of biomass industrial waste are installed and connected. Taking furfural slag as an example,

[0016] The furfural slag is loaded into the hopper of the belt conveyor 1 with a forklift and falls onto the vibrating screen 2 along with the belt conveyor. The large particles and sundries are screened out by the vibrating screen 2 and then crushed and returned to the vibrating screen. The furfural with qualified particle size The slag is sent to the scattered air dryer for drying along with the heated air. In the steam heat exchanger 3 , air and steam enter into the steam heat exchanger 3 , condensed water flows out from the bottom, and the heated air is sent into the diffuse air dryer 4 .

[0017] The pipe diameter of the scattered airflow dryer 4 is alternately reduced and expanded, so as to fully exert the high heat and mass transfer function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com