Umbrella-shaped liquid atomizer and application thereof

A liquid atomization and umbrella-shaped technology, which is applied in the direction of production fluid, injection device, wellbore/well components, etc., can solve the problem that the fracturing flowback fluid cannot be burned, so as to save combustion processing time, reduce pollution and personnel safety damage, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

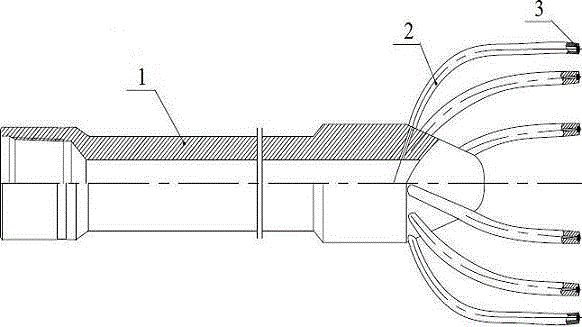

[0018] This embodiment provides a figure 1 , 2 The umbrella-shaped liquid atomizer shown includes an inlet straight pipe body 1 and a plurality of outlet elbow bodies 2. One end of the inlet straight pipe body 1 is open and the other end is sealed. The plurality of outlet elbow bodies 2 are The sealing end of the inlet straight pipe body 1 is uniformly arranged circumferentially and forms an umbrella shape. One end of each outlet elbow body 2 communicates with the inlet straight pipe body 1 , and the other end is connected with an atomizing nozzle 3 .

[0019] The liquid enters from the inlet straight pipe body 1, and is sprayed and atomized by the atomizing nozzle 3 through the outlet elbow body 2. Since the liquid is divided into multiple paths from the inlet straight pipe body 1, and the atomizing nozzle 3 has a small aperture, it forms a semicircle Atomized and sprayed.

Embodiment 2

[0021] On the basis of Embodiment 1, this embodiment provides an umbrella-shaped liquid atomizer, and the diameter of the atomizing nozzle 3 is 0.3mm~1.8mm. There are 12 outlet elbow bodies 2 .

[0022] The inlet straight pipe body 1 and the outlet elbow body 2 are welded, and the outlet elbow body 2 and the atomizing nozzle 3 are threaded. In order to facilitate disassembly, cleaning, replacement and maintenance.

[0023] Both the inlet straight pipe body 1 and the outlet elbow body 2 are 304 stainless steel pipes. Temperature resistance 800 ℃, corrosion resistance, good processing performance, high toughness.

[0024] The atomizing nozzle 3 is made of tungsten carbide YG8 material. Cemented carbide tungsten carbide YG8 material, heat treatment hardness up to HRC92~95, has high erosion resistance.

Embodiment 3

[0026] On the basis of the foregoing embodiments, this embodiment provides the use of an umbrella-shaped liquid atomizer. The umbrella-shaped liquid atomizer is used in the combustion treatment process of fracturing flowback fluid to treat fracturing flowback fluid. Nebulize.

[0027] The fracturing flowback fluid is the fracturing flowback fluid in the sewage tank. After the fracturing flowback fluid enters the umbrella-shaped liquid atomizer through the pipeline and the pump, it is directly sprayed onto the gas combustion flame of the acid discharge cylinder through the atomizing nozzle 3 combustion.

[0028] Umbrella-shaped liquid atomizer is used to improve the combustion efficiency of fracturing flowback fluid, so that the fracturing flowback fluid in the sewage tank passes through the liquid atomizer to form a mist spray, thereby increasing the flow rate of fracturing flowback liquid in the acid discharge cylinder Combustion at all places covers the contact area, and bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com