Energy-saving high-efficient gas normal-pressure boiler

A gas and normal pressure technology, applied in the field of gas boilers, can solve the problems of low thermal efficiency, large gas consumption, insufficient combustion, etc., and achieve the effect of reducing gas consumption, solving large gas consumption and improving thermal energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

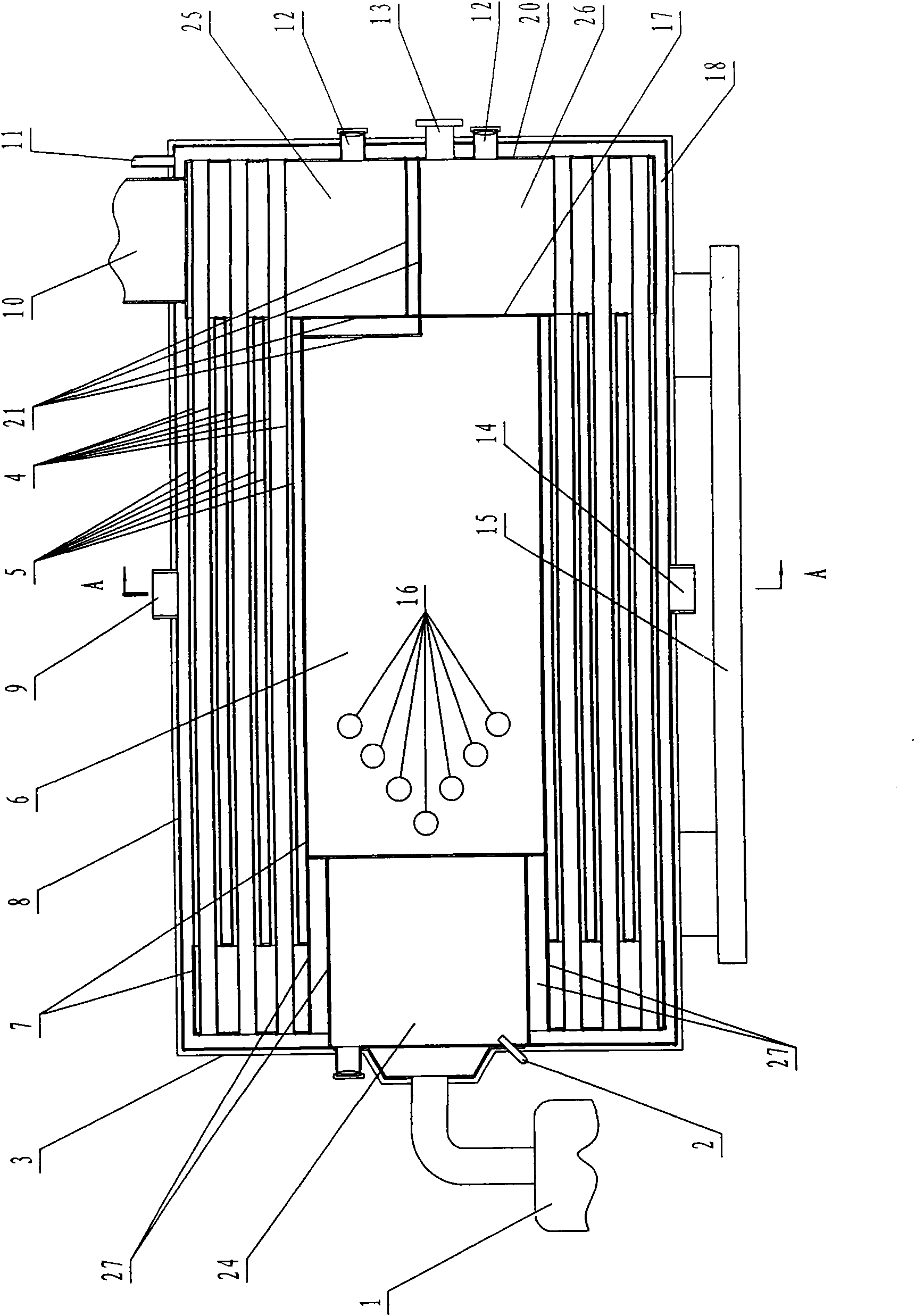

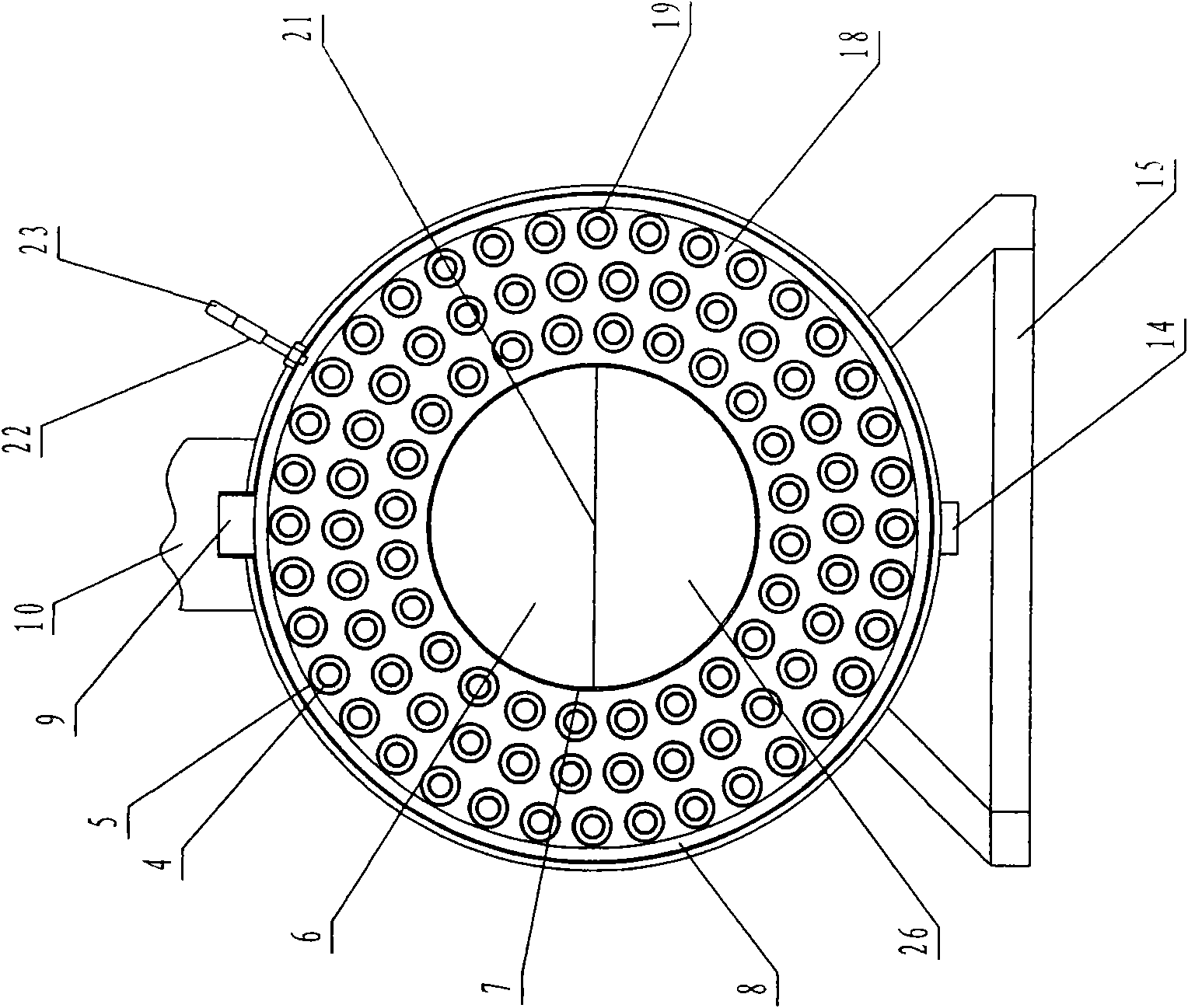

[0011] Energy-saving and high-efficiency gas-fired atmospheric boiler, including furnace shell 3, fire tube 5, furnace liner 7, furnace outer liner 8, inner flower plate 17, furnace 6 surrounded by furnace liner 7, fire tube 5, furnace liner 7 , the water interlayer 18 surrounded by the furnace outer bladder 8 and the inner flower disc 17, and the first vortex cyclone combustion chamber 24 and the second vortex cyclone combustion chamber respectively located at the front and rear ends of the furnace shell 3; The water pipes 4 whose ends are all communicated with the water interlayer 18, the two ends of the water pipes 4 are provided with an outer disk 20 whose edge is fixed to the side wall of the furnace liner 7 and used to support the water pipes 4; the second vortex cyclone combustion chamber is provided with double-layer transverse partition plate 21, the water interlayer 18 extends between the double-layer transverse partitions 21, the two sides of the edge of the transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com