Display shell preparation method for increasing explosion diameter

A technology for fireworks bombs and bud opening medicines, which is applied in the field of preparation of fireworks bombs that increase the diameter of bud openings, and can solve problems such as unfavorable safety and environmental protection, residues of medicine grains, and particle adhesion, so as to improve viewing effects and reduce smoke , The effect of increasing the firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

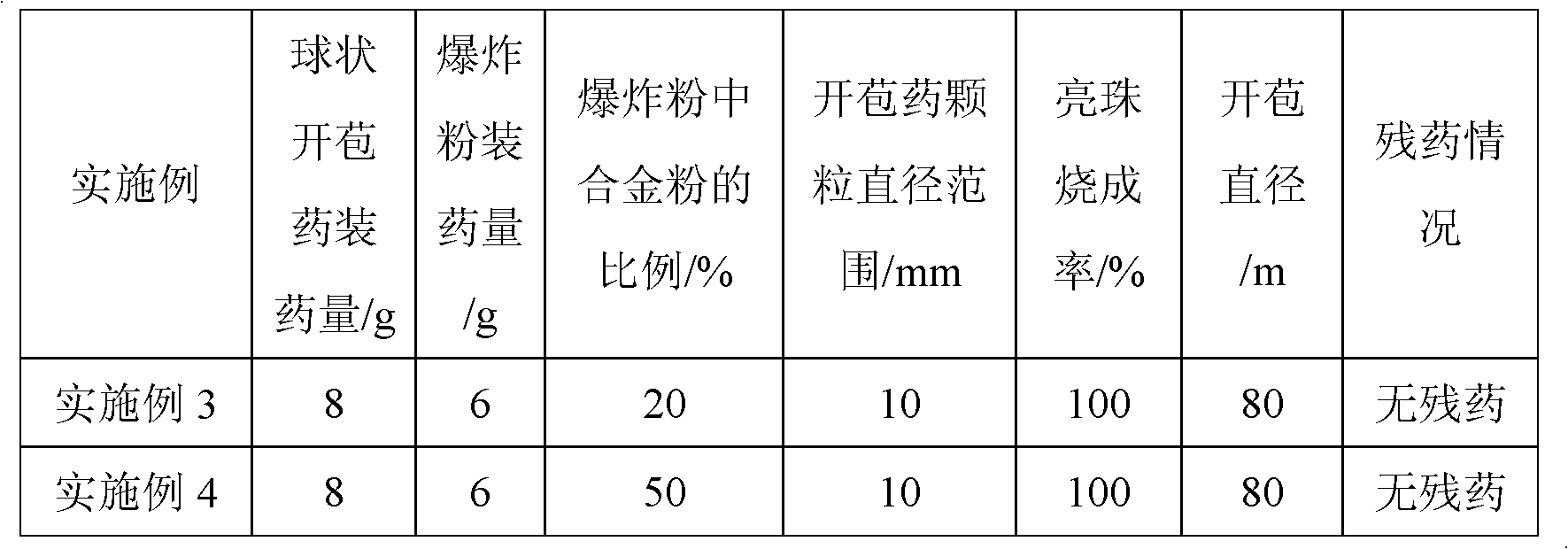

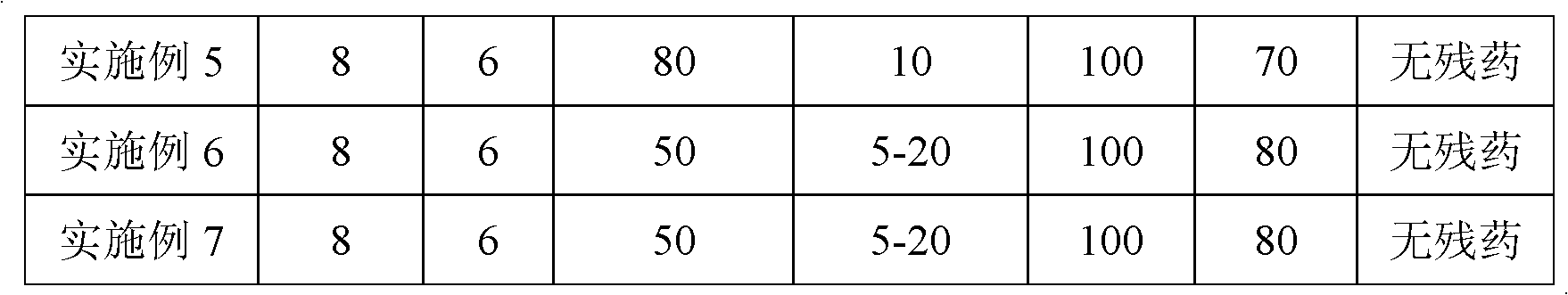

Examples

preparation example Construction

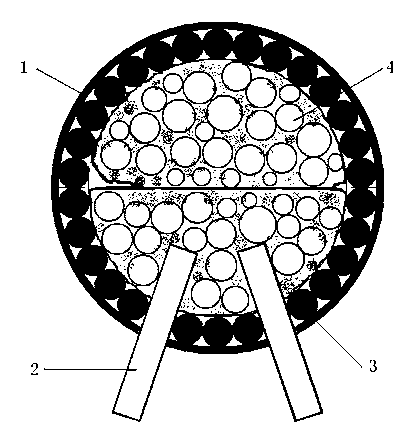

[0015] combine figure 1 , a kind of preparation method of the display shell that improves opening bud diameter, comprises the following steps:

[0016] Step 1, bonding the granular micropore medicine into a pellet-shaped bud-opening medicine, the pellet-shaped bud-opening medicine is formed by using granular micropore fireworks medicine through an organic adhesive, and the described The diameter range of the pellet-shaped bud-opening medicine is 5mm-20mm, and the organic binder is an aqueous solution of a water-soluble binder, an aqueous solution of starch or modified starch, an ethanol solution of ethyl cellulose, polyvinyl butyral The ethanol solution containing nitrocellulose, the sol or the emulsion containing nitrocellulose, the mass percentage of the pellet-shaped bud-opening drug is composed of 82%-99% of the granular micro-pore fireworks drug, and the organic binder is 0.2-10%.

[0017] The granular microporous fireworks medicine is the prior art of the inventor's pat...

Embodiment 1

[0028] combine figure 1 , select the 3-inch fireworks bomb as an example, use the pellet-shaped drug blocks bonded by granular micro-aerosols as the bud-opening drug, the diameter of the outer spherical shell is 76mm, the thickness is 3mm, and the diameter of the bright beads is 10mm.

[0029] The preparation method and process of the granular micro-aerosol are as follows: the granular micro-pore firework drug is prepared by using single-base waste gunpowder containing 97.0% of nitrocellulose and 1.0% of diphenylamine (stabilizer) as raw materials. The single-base waste powder is preliminarily crushed in the presence of a large amount of water, and the particle diameter is controlled to be no more than 3mm. The single-base waste powder with water is added to the forming reactor, and the moisture content of the wet single-base waste powder is 15%. -30%, add ethyl acetate solvent 10 times the mass of single-base waste propellant powder under stirring, stir and dissolve at 45°C-6...

Embodiment 2

[0036]The granulated microporous fireworks medicine is prepared by using the raw material medicine granules with nitrocellulose content of 99% and diphenylamine (stabilizer) content of 0.5%. First add the raw material medicine pellets into the forming reactor, add ethyl acetate solvent 10 times the mass of the raw medicine medicine pellets under stirring, stir and dissolve at 45°C-60°C for 30-60min, and then continuously pour into the system Add water; carry out emulsification and foaming operation under stirring state, continue to add water in this step, the amount of water added is 6 times of the mass of the raw material granules, and then continue to stir at 50-60°C for 30min-60min, the system When the temperature is adjusted to 65°C-68°C, an aqueous solution containing 0.5% gelatin, which is 6 times the mass of the raw material granules, is added into the material system to disperse into balls. Continue to maintain the temperature at 65°C-68°C, and disperse for 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com