Gas water heater and method for removing noise of gas water heater

A technology of gas and gas valves, which is applied in the direction of combustion methods, burners, fluid heaters, etc., and can solve problems such as high noise and insufficient combustion of gas water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

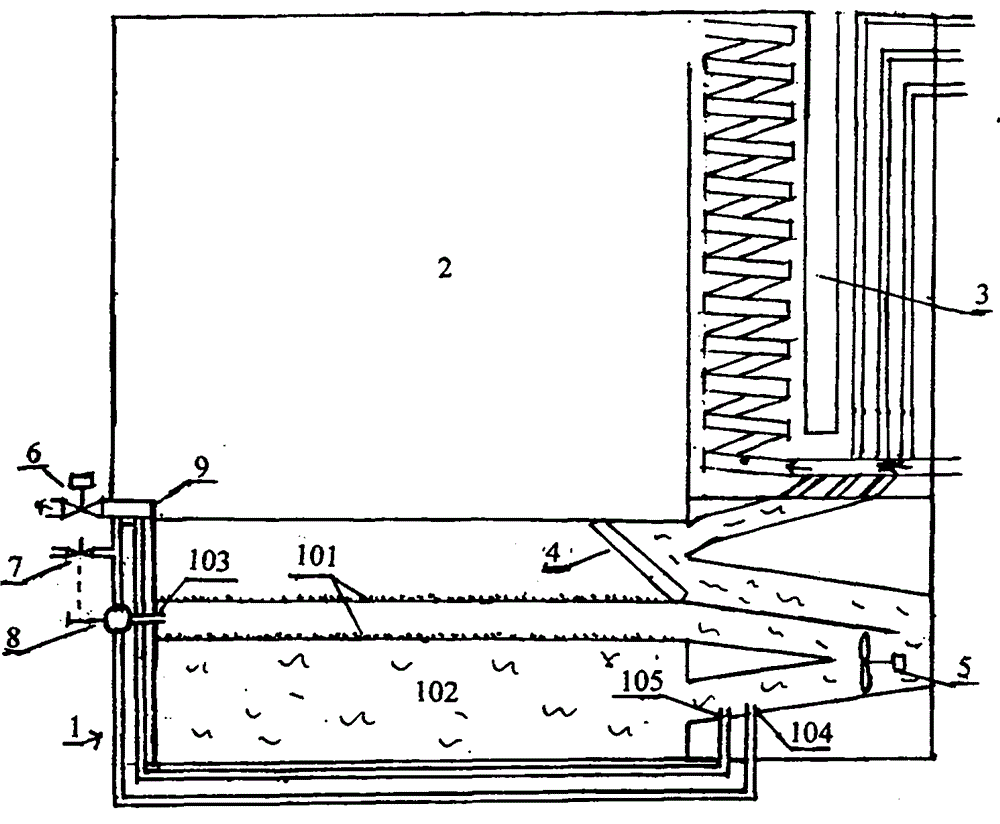

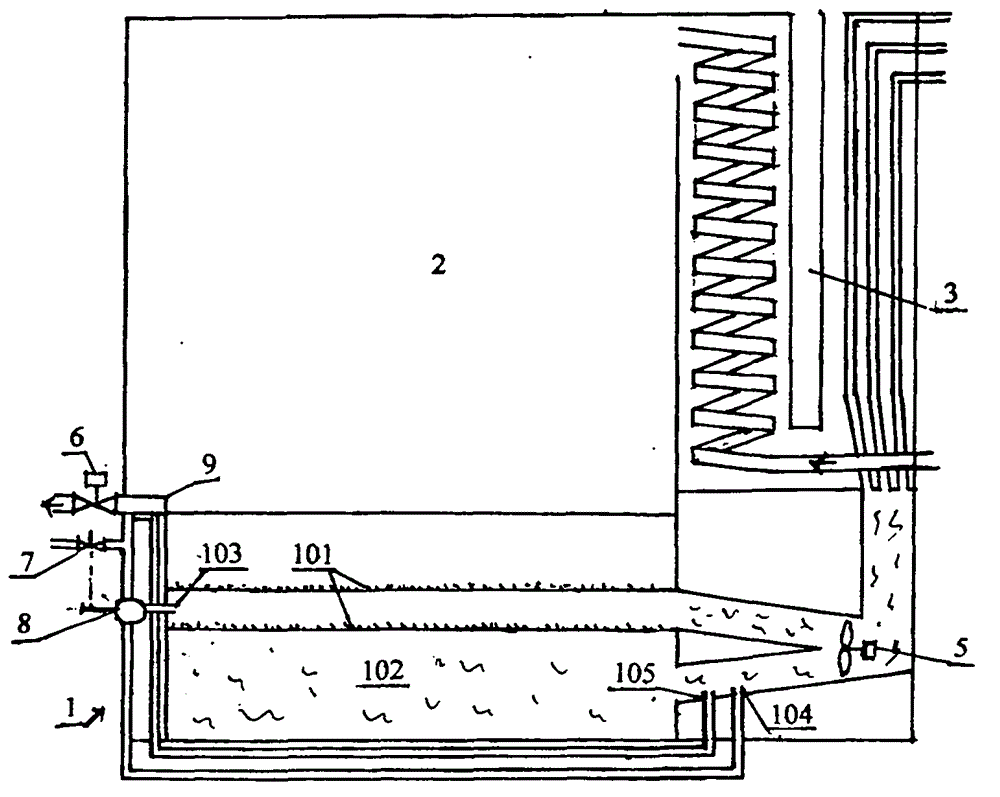

[0011] figure 1 As shown, the gas water heater of the present invention equipped with a semiconductor thermoelectric power generation device is mainly composed of a burner 1, a heat exchanger 2, a condenser 3, an axial flow fan 5, an electronic ignition and gear adjustment gas valve 8, and a gas valve for automatic water temperature adjustment. Valve 9, ion or pressure fire protection gas valve 7 are formed. The burner 1 is composed of a combustion layer, a premixing chamber 102, a gas nozzle and an electronic pulse igniter. When igniting, twist the water temperature to automatically adjust the gas valve 9, select a suitable set water temperature, and then press down the electronic ignition and gear adjustment Turn the knob of the gas valve 8, and then twist the knob of the electronic ignition and gear adjustment gas valve 8. After ion or pressure fire protection, the first gas of the gas valve 7 passes through the depressed electronic ignition and the gear adjustment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com