Method for producing large-size disc-type cast iron parts by means of lost foam casting

A technology of lost foam casting and casting production, which is applied to casting molding equipment, molds, mold components, etc. It can solve problems such as slag holes, improper selection of beads, and deformation of casting surface dimensions, so as to prevent deformation and improve surface quality. The effect of quality and stability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

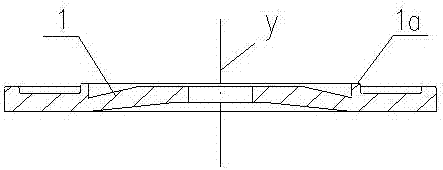

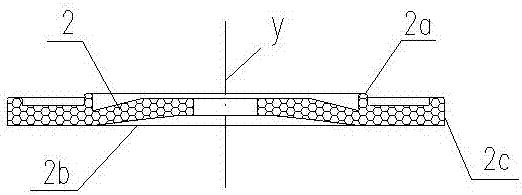

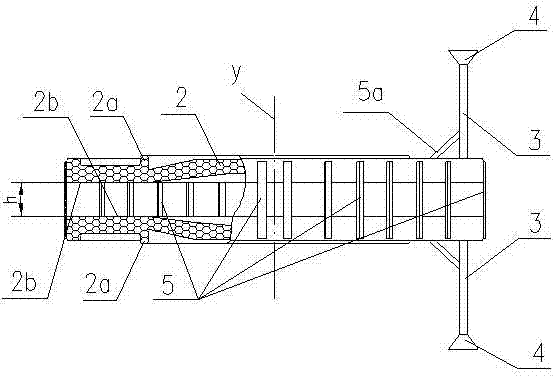

[0087] An enterprise needs to produce 6 pieces of friction discs 11, such as Figure 7 , Figure 8 As shown, the diameter of the outer circle is φ1050mm, the diameter of the inner circle is 640mm, the thickness is 32mm, and the thin-wall heat dissipation part 11a is 5mm.

[0088] The manufacturer of the STMMA beads used in this example - Zhejiang Kester New Material Co., Ltd.; the manufacturer of the hot melt adhesive used - Huachun Hot Melt Adhesive Products Co., Ltd.; the manufacturer of the special paint for lost foam used - Suizhou Hongsheng Industry and Trade Co., Ltd.; the steam pre-foaming machine used, model RO-YF, the manufacturer - Hebei Ruiou Lost Foam Technology Co., Ltd.; the model forming machine used, the manufacturer - Yantai Sifang Foundry Equipment Engineering Co., Ltd.; Paint mixer used: model GFS-2N-Y, manufacturer—Shanghai Puzhong Chemical Machinery Co., Ltd. In addition, the lost foam runners, sprue cups, wooden strips, profiling cold irons, and metal f...

Embodiment 2

[0118] In order to further verify the feasibility of the technical solution of the present invention, a certain enterprise subsequently produced 6 friction discs 11 and tested them.

[0119] The STMMA beads used in the second embodiment, hot melt adhesive, special paint for lost foam, steam pre-foaming machine, model forming machine, paint mixer, profiling cold iron, metal forming mold, sand box, vibrating table, Baume degree The tester, coating box, hand saw, and lost foam vacuuming system are the same as in Example 1. In addition, the used lost foam runners, sprue cups, and wooden strips have been re-completed and have been configured on the job site.

[0120] Next, continue by Figure 7 , Figure 8 and continue to refer to Figure 4 , Figure 5 , Figure 6 , illustrating a method of lost foam casting of a large-size disc type iron casting in the present invention—the friction disc 11, the steps are as follows:

[0121] 1) Bead selection: According to the wall thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com