A circular flow energy-saving smokeless oven

A circulating flow and oven technology, which is applied in the field of circulating flow energy-saving smokeless ovens, can solve the problems of large heat loss, environmental pollution, single function, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

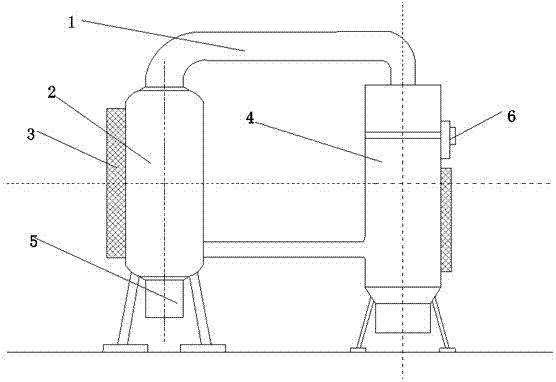

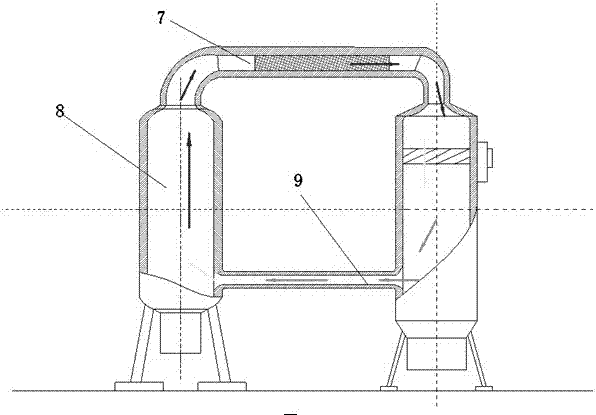

[0037] Such as figure 1 As shown, the circulating flow energy-saving smokeless oven includes a double circulation system 1, a main oven 2, a grill system 3, an auxiliary oven 4, a bio-grease collector 5 and a power supply device 6; the main oven 2 passes The double circulation system 1 communicates with the auxiliary oven 4, the main oven 2 and the auxiliary oven 4 are provided with a grill system 3, the collection platform at the bottom of the main oven 2 and the auxiliary oven 4 is connected to the bio-grease collector 5, and the power supply device 6 is installed on the side of the auxiliary oven 4 to provide electric energy. The temperature of the upper and middle parts of the main oven 2 is higher than that of the lower part, and the temperature of the upper and middle parts of the auxiliary oven 4 is lower than that of the lower part.

Embodiment 2

[0039] Such as figure 1 As shown, the circulating flow energy-saving smokeless oven includes a double circulation system 1, a main oven 2, a grill system 3, an auxiliary oven 4, a bio-grease collector 5 and a power supply device 6; the main oven 2 passes The double circulation system 1 communicates with the auxiliary oven 4, the main oven 2 and the auxiliary oven 4 are provided with a grill system 3, the collection platform at the bottom of the main oven 2 and the auxiliary oven 4 is connected to the bio-grease collector 5, and the power supply device 6 is installed on the side of the auxiliary oven 4 to provide electric energy. The temperature of the upper and middle parts of the main oven 2 is higher than that of the lower part, and the temperature of the upper and middle parts of the auxiliary oven 4 is lower than that of the lower part.

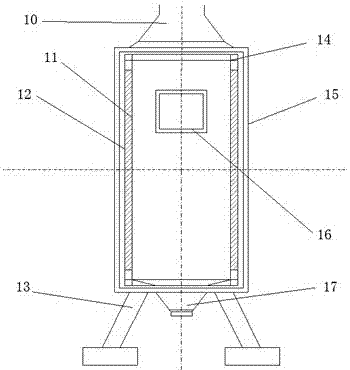

[0040] The main oven 2 includes a horn smoke exhaust port 10, a high-power infrared electric heating tube 11, a fly ash foam brick 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com