Full-load selective catalytic reduction (SCR) denitration system of coal-fired boiler

A coal-fired boiler, full-load technology, applied in the direction of lighting and heating equipment, gas treatment, membrane technology, etc., can solve the problem that the system cannot be put into normal operation, so as to facilitate the removal of NOx, increase the temperature of raw flue gas, and reduce the The effect of ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

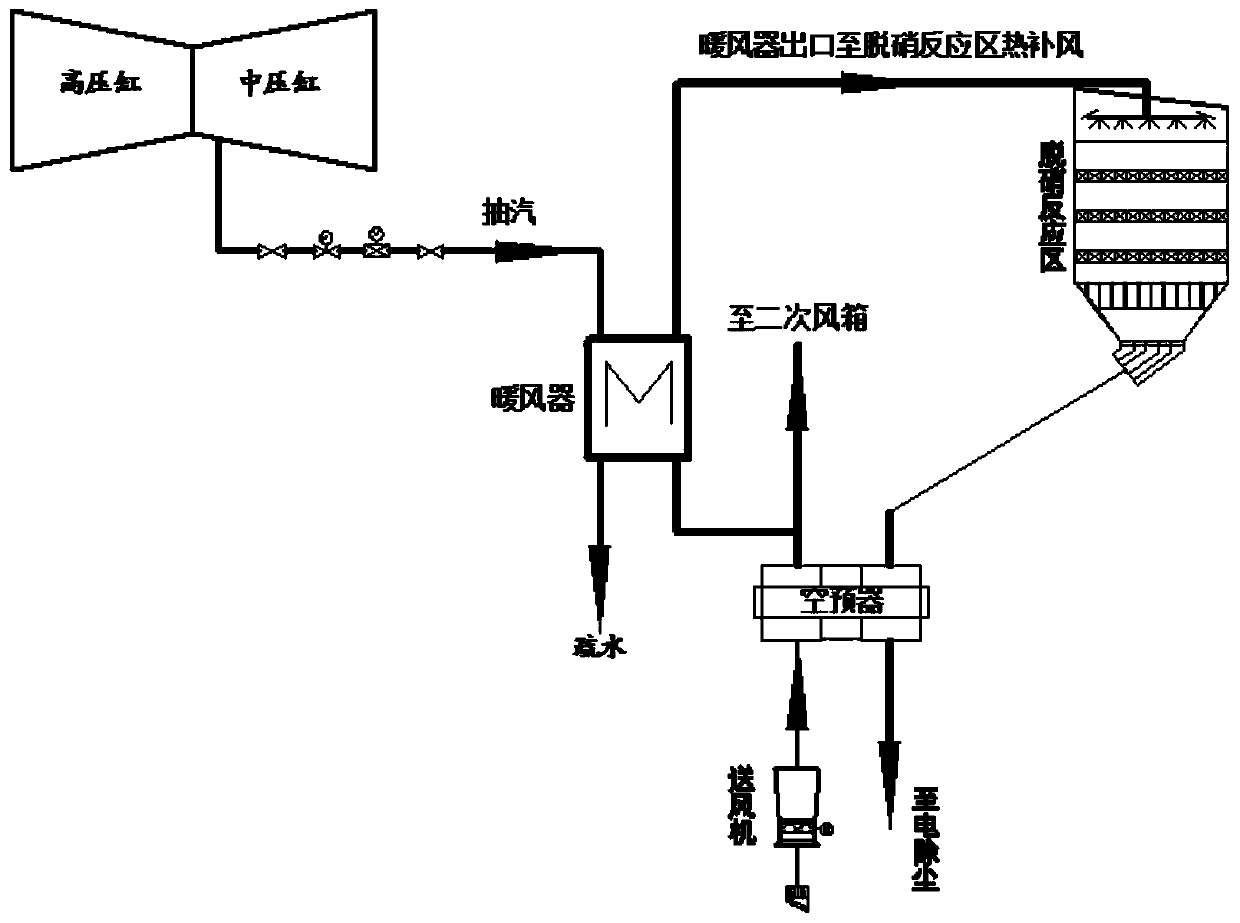

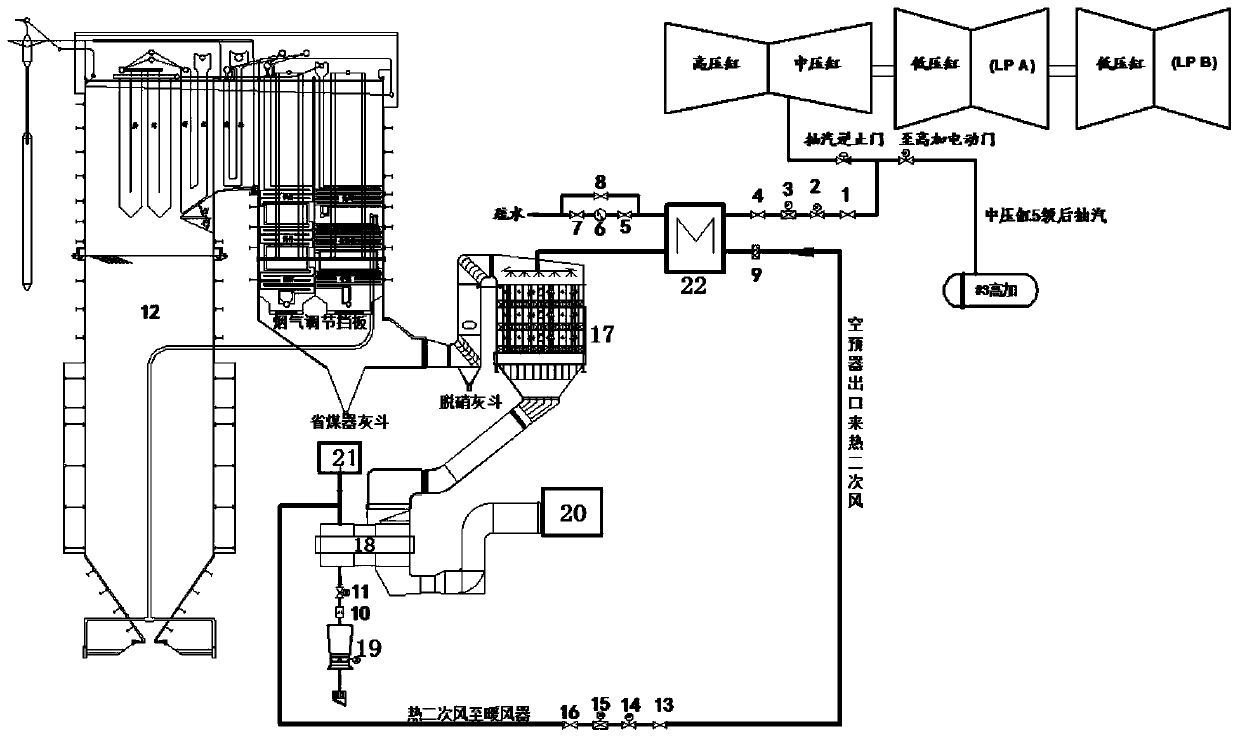

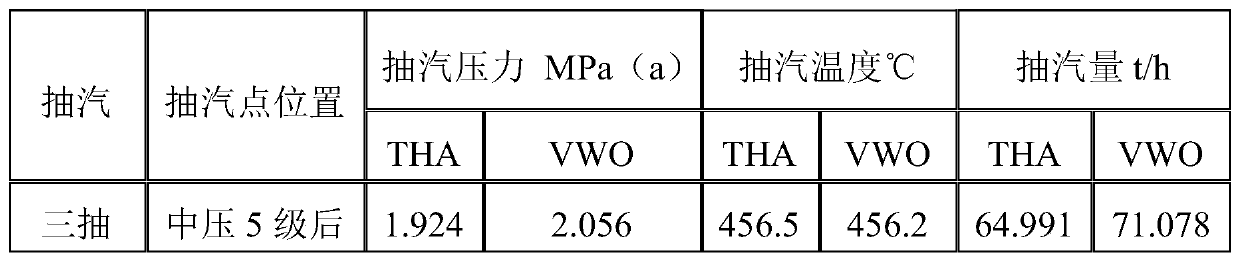

[0033] In view of the problem that the SCR denitrification device cannot operate when the coal-fired unit is started or operated at low load, this application proposes a full-load SCR denitrification system for coal-fired boilers to reduce nitrogen oxide emissions. Under normal circumstances, since the installed quantity of coal-fired generating units is generally configured with more than two units, when more than one unit is in operation, and when the other unit is in the startup or shutdown phase, this system uses the high-temperature extraction steam of the operating unit, Heating the hot secondary air of the start-up or shutdown unit, spraying the further heated high-temperature secondary air into the catalyst reaction area through reasonable flow field optimization, and mixing with the original hot flue gas in the tail flue, it can Directly increase the temperature field in the catalyst reaction area.

[0034] Such as figure 1 As shown, the system includes a denitration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com