Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

A technology of organic pollution and remediation system, applied in the restoration of contaminated soil, separation methods, chemical instruments and methods, etc., can solve unreasonable tail gas treatment design, low heat energy utilization efficiency, dioxin adsorption effect needs further verification, etc. problems, to achieve the effect of reducing the risk of secondary pollution, reducing the consumption of water resources, and efficient thermal desorption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

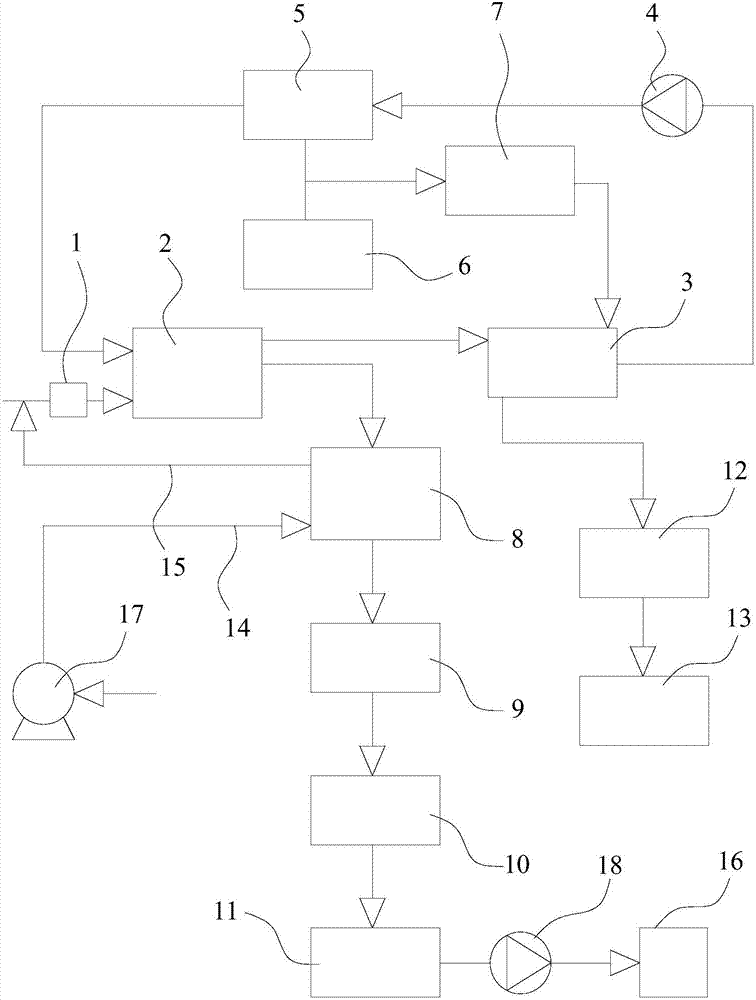

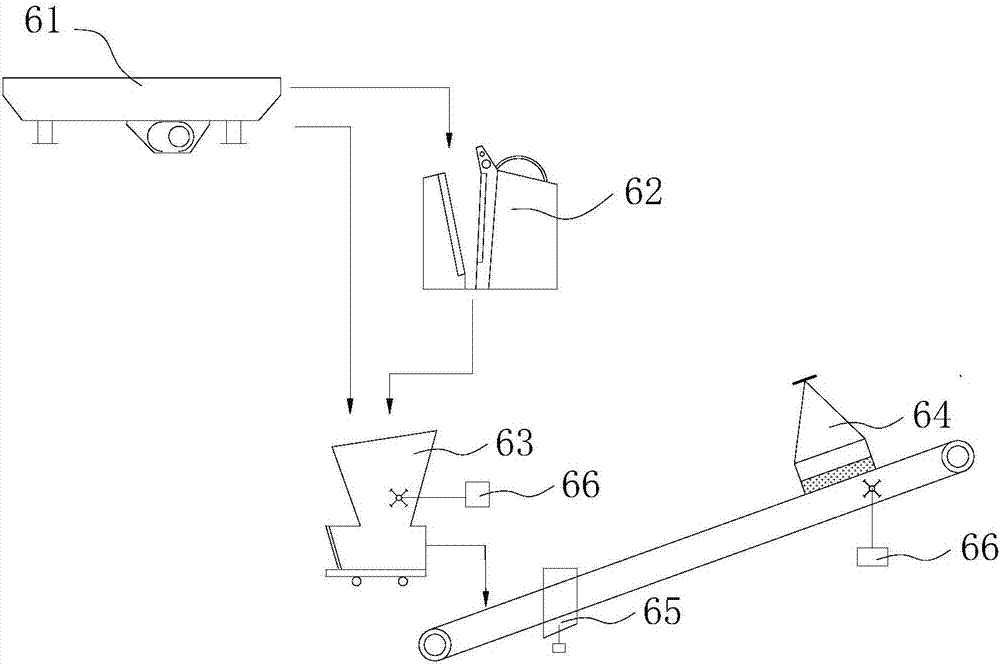

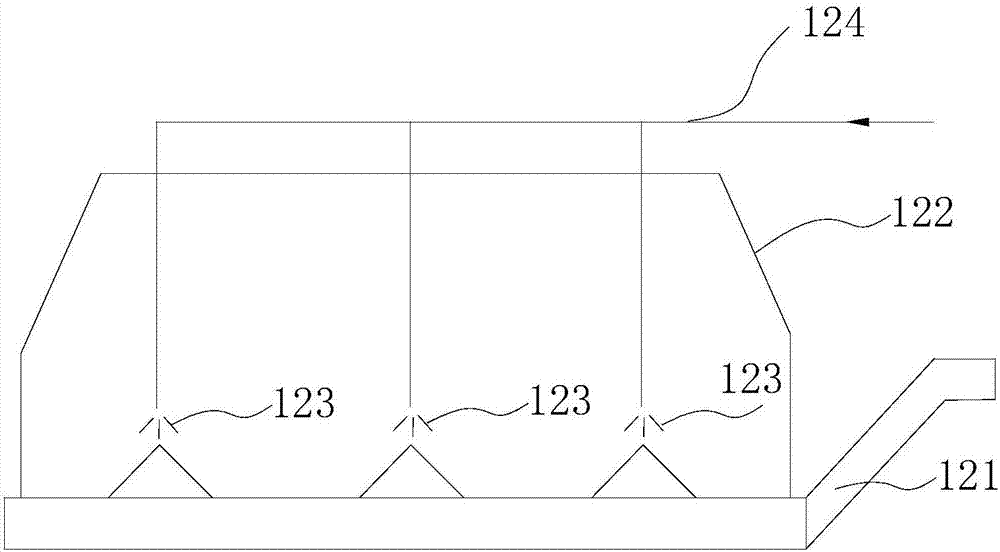

[0032] Such as figure 1 As shown, the ectopic heat desorption restoration system for organically polluted soils with high efficiency utilization of waste heat involved in this embodiment includes: a burner 1, a high temperature oxidation chamber 2, a rotary kiln heating treatment system 3, an induced draft fan 4, a cyclone Dust collector 5, soil pretreatment system 6, feed system 7, air heat exchanger 8, quench tower 9, bag filter 10, deacidification tower 11, soil humidification and cooling device 12, soil discharge system 13, normal temperature air inlet 14. High-temperature air outlet 15, chimney 16, blower 17 and induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com