Household up-draft biomass gasification device

A gasification device and biomass technology, applied in the direction of manufacturing combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the gas sensible heat loss of gasification furnace, increase the cost of biomass gasification, and keep the wall of gasification furnace insulated Insufficient and other problems, to achieve the effect of low operating cost, reduced carrying heat loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

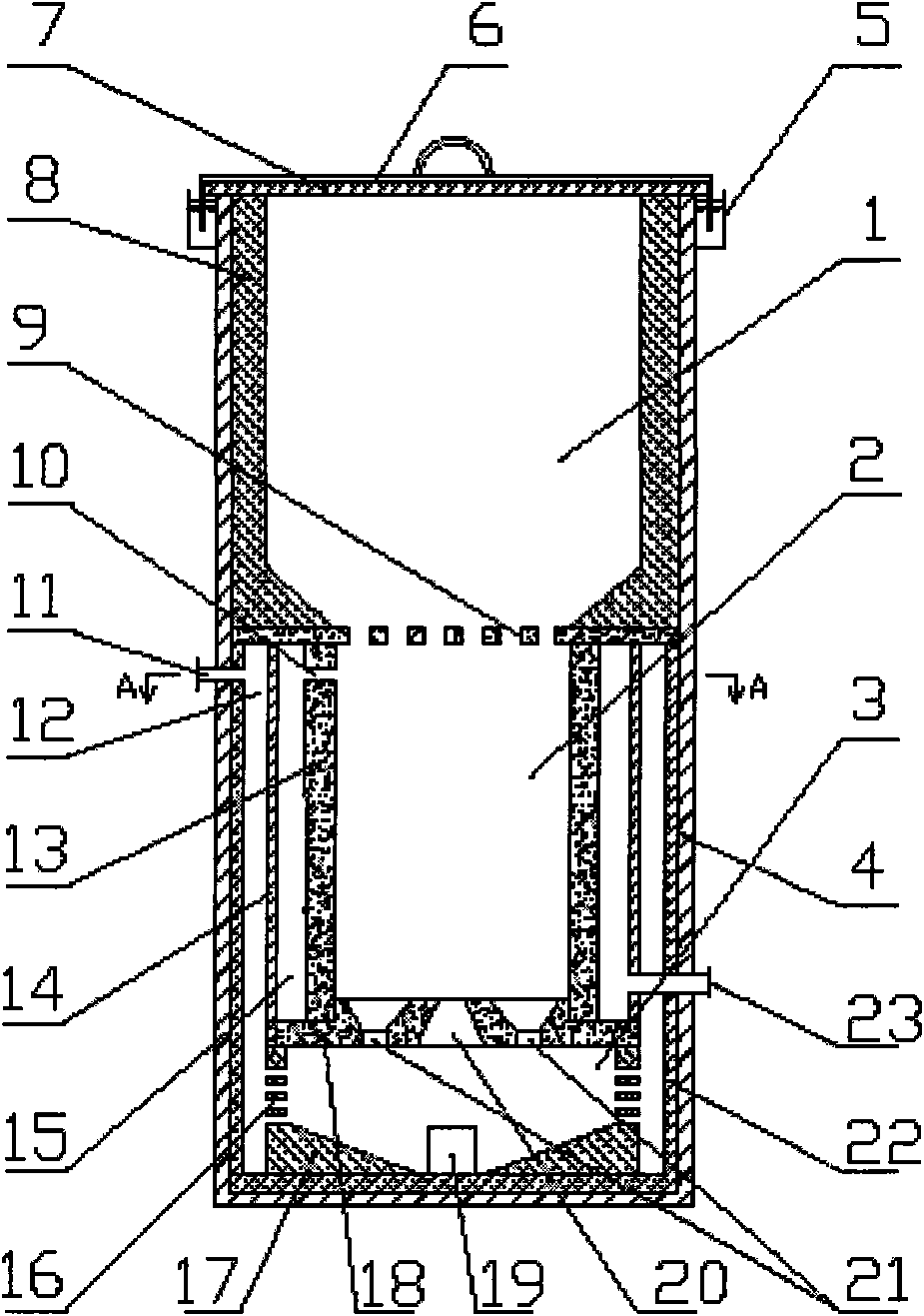

[0033] see below figure 1 , the outer wall 4 of the gasification furnace is an upright cylindrical structure, and its internal structure is composed of a retort chamber 1 in the upper section, a main gasification chamber 2 in the middle section, and an ash chamber 3 in the lower section. The grate 18 is divided.

[0034] The retort chamber 1 is surrounded by a circular outer wall 4 and an upper insulation layer 8 , with an end cover 6 on the top, and a water seal ring groove 5 outside the upper part of the outer wall 4 .

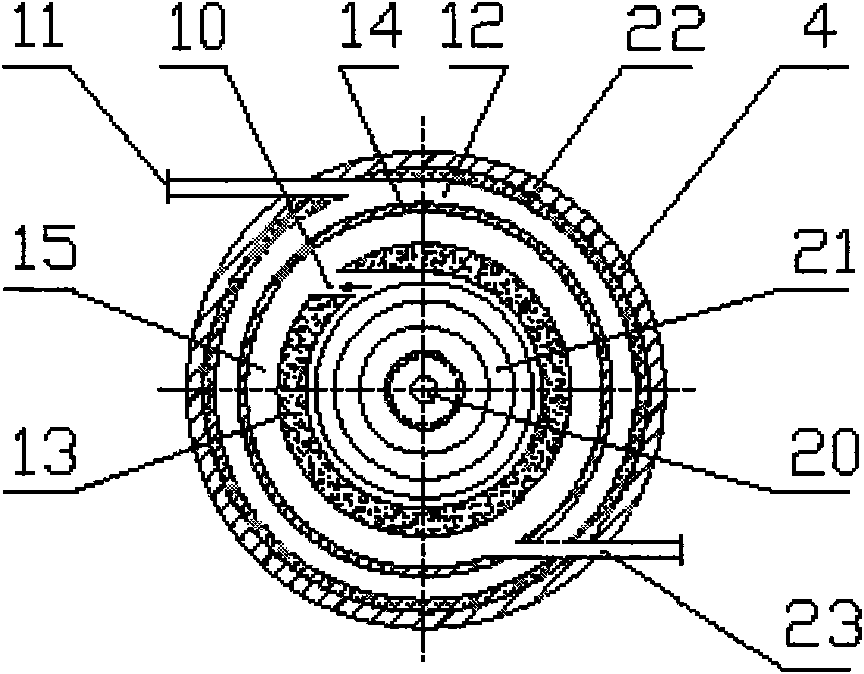

[0035] The main gasification chamber 2 is composed of a radiation cylinder 13, a heat conduction cylinder 14, a lower insulation layer 22 and an outer wall 4 from inside to outside in the radial direction, and encloses two annular spaces. On the side wall of the furnace body at the upper part of the main gasification chamber 2, an air inlet 11 penetrating through the lower insulation layer 22 is set; on the upper side wall of the radiant cylinder 13, a gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com