Burning device and process for oil shale fluidized bed

A technology of oil mother shale and fluidized bed, which is applied in the field of comprehensive utilization of oil mother shale, can solve the problems such as difficulty in fully utilizing the calorific value and ash content of oil mother shale, low utilization value of ash residue, incomplete combustion, etc., so as to avoid flow loss and deposition. , Significant economic benefits, uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

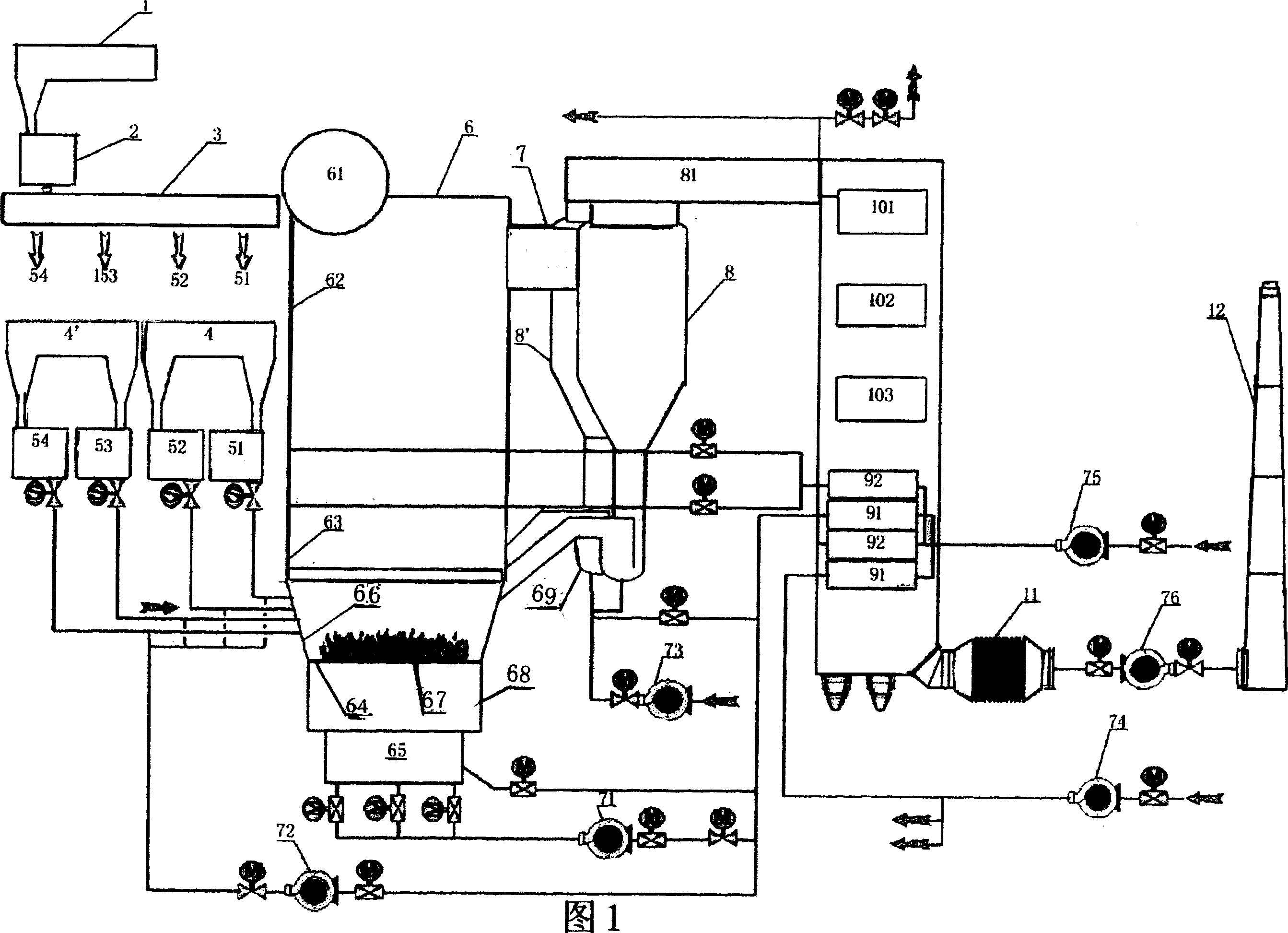

[0018] With a fluidized bed boiler 6 as the center, a boiler combustion system device is arranged upstream of the device. Set up a set of material conveying system including lifting, conveying and two-stage crushing to convey raw coal and oil shale into the boiler for combustion, and connect to a set of cyclone separators 8 and 8' at the outlet above the furnace through the flue 7. The above conveying system includes oil shale bin 1, oil shale feeder 2, chain conveyor 3, coal feeder bin 4, 4', and 1# coal feeder 51, 2# coal feeder 52, 3# coal feeder 53 , and 4# coal feeder 54; after the preheated air is pressurized by the booster fan 72, it is connected to the coal feeder system. Also be connected with the preheating air pipeline that pressurizes through ignition booster blower 71 at furnace bottom 65 places, blast into hot blast in furnace. The bottom of the group of cyclone separators 8 and 8' is connected with a "J" valve feeder 69, and then connected to the lower chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com