Control system for flue gas oxygen content of layer combustion boiler based on flue gas recirculation

A technology of flue gas recirculation and boiler flue gas, which is applied in the direction of controlled combustion, solid fuel combustion, and combustion methods. The effect of large load variation range, reduction of initial emission concentration, and reduction of manual operation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

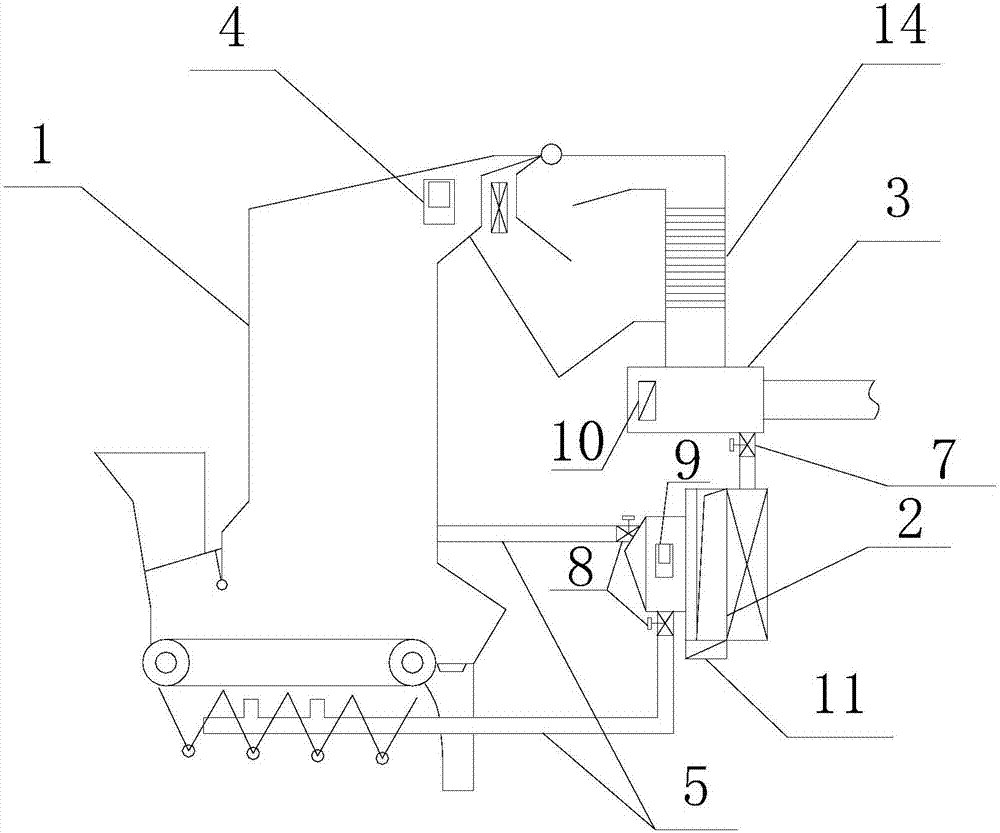

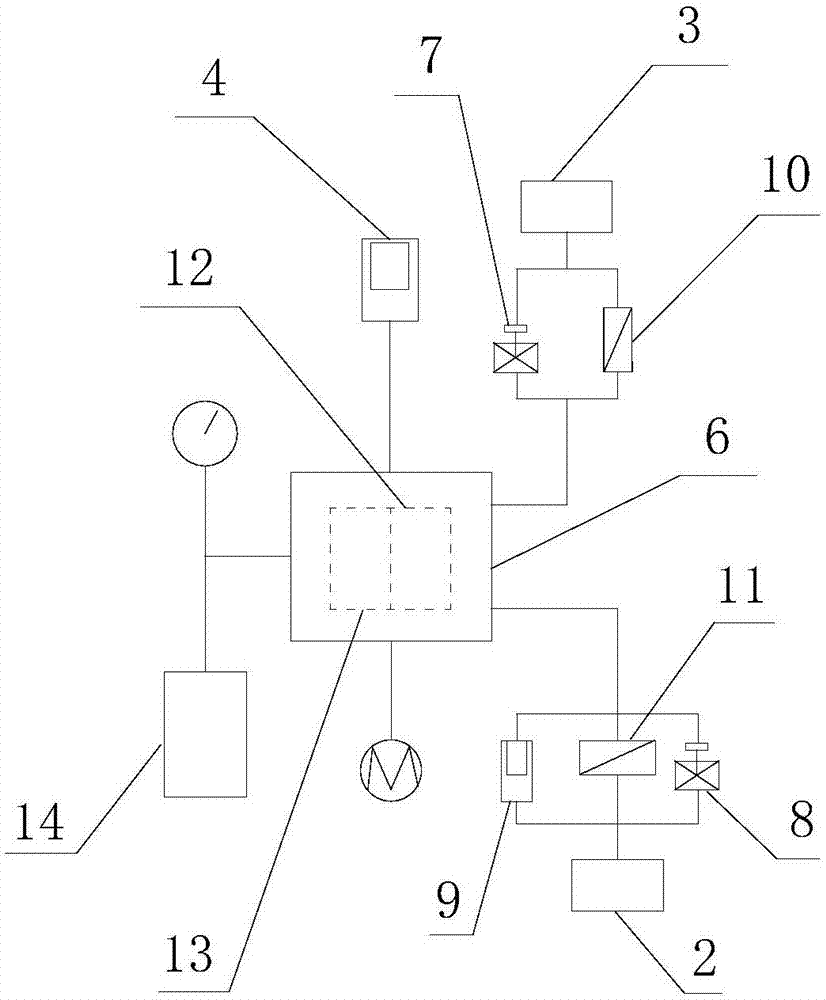

[0024] Such as Figure 1 to Figure 2 As shown, a layer-fired boiler flue gas oxygen content control system based on flue gas recirculation is mainly composed of a layer-fired boiler 1, a blower 2, a flue gas recirculation fan 3, a zirconia analyzer 4, an air duct 5 and a DCS The system (or PLC system) consists of 6, the furnace of the layer-fired boiler 1 is connected with the blower 2 through the air duct 5, the smoke outlet of the layer-fired boiler 1 is installed with a zirconia analyzer 4, and the smoke outlet of the layer-fired boiler 1 A flue gas recirculation fan 3 is arranged on the channel, and the flue gas recirculation fan 3 is connected to the air inlet of the blower 2 through the air pipe 5, and the flue gas recirculation fan 3 is connected with a first fan frequency conversion controller 10 and an electric regulating valve 7 , the electric regulating valve one 7 is installed on the air pipe 5 connecting the flue gas recirculation fan 3 to the air inlet of the blo...

Embodiment 2

[0026] Such as Figure 1 to Figure 2 As shown, a layer-fired boiler flue gas oxygen content control system based on flue gas recirculation is mainly composed of a layer-fired boiler 1, a blower 2, a flue gas recirculation fan 3, a zirconia analyzer 4, an air duct 5 and a DCS The system (or PLC system) consists of 6, the furnace of the layer-fired boiler 1 is connected with the blower 2 through the air duct 5, the smoke outlet of the layer-fired boiler 1 is installed with a zirconia analyzer 4, and the smoke outlet of the layer-fired boiler 1 A flue gas recirculation fan 3 is arranged on the channel, and the flue gas recirculation fan 3 is connected to the air inlet of the blower 2 through the air pipe 5, and the flue gas recirculation fan 3 is connected with a first fan frequency conversion controller 10 and an electric regulating valve 7 , the electric regulating valve one 7 is installed on the air pipe 5 connecting the flue gas recirculation fan 3 to the air inlet of the blo...

Embodiment 3

[0029] Such as Figure 1 to Figure 2 As shown, a layer-fired boiler flue gas oxygen content control system based on flue gas recirculation is mainly composed of a layer-fired boiler 1, a blower 2, a flue gas recirculation fan 3, a zirconia analyzer 4, an air duct 5 and a DCS The system (or PLC system) consists of 6, the furnace of the layer-fired boiler 1 is connected with the blower 2 through the air duct 5, the smoke outlet of the layer-fired boiler 1 is installed with a zirconia analyzer 4, and the smoke outlet of the layer-fired boiler 1 A flue gas recirculation fan 3 is arranged on the channel, and the flue gas recirculation fan 3 is connected to the air inlet of the blower 2 through the air pipe 5, and the flue gas recirculation fan 3 is connected with a first fan frequency conversion controller 10 and an electric regulating valve 7 , the electric regulating valve one 7 is installed on the air pipe 5 connecting the flue gas recirculation fan 3 to the air inlet of the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com