Automatic control system for left and right tracks to travel synchronously

An automatic control system and crawler technology, which is applied in the direction of control drive, crawler vehicles, motor vehicles, etc., can solve the problems that cannot meet the requirements of use, cannot achieve synchronization, and the size of manual control force is different, so as to reduce the intensity of manual operation and improve the response. Sensitive, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

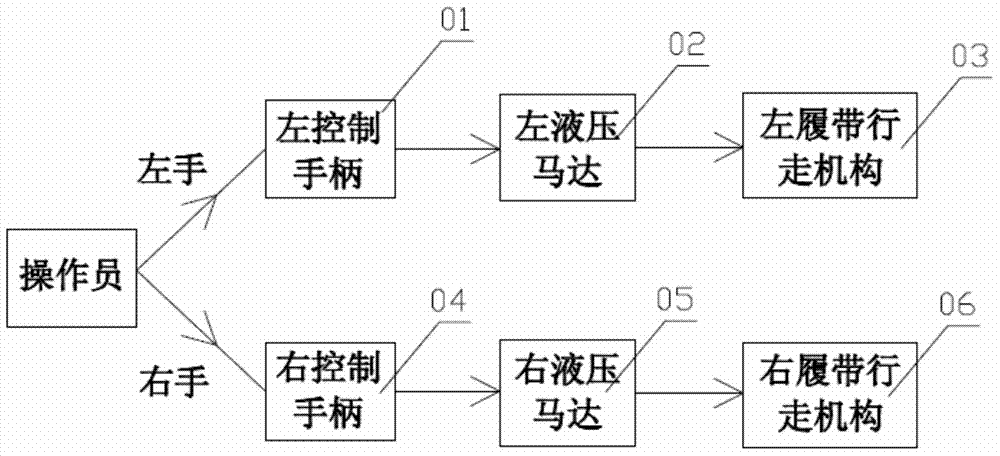

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

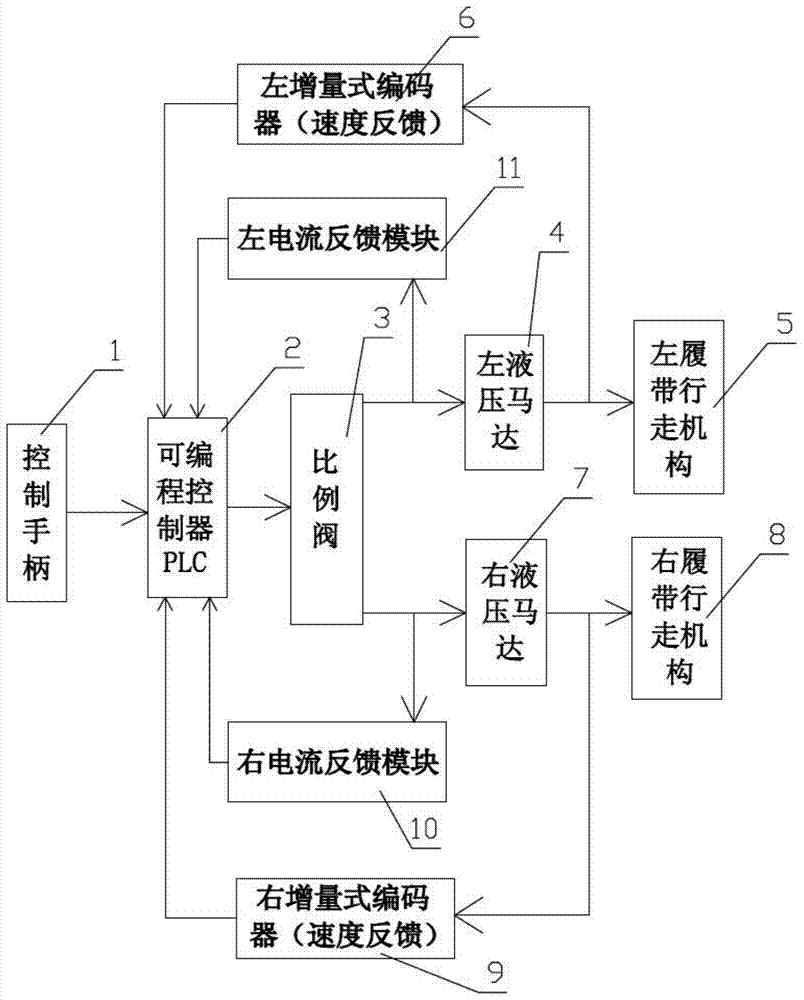

[0016] combined with figure 2 And attached image 3 , an automatic control system for synchronous walking of the left and right crawlers, which includes a control handle 1, a programmable logic controller PLC 2, a proportional valve 3, a left hydraulic motor 4, a left crawler mechanism 5, a left incremental encoder 6, a right Hydraulic motor 7, right crawler walking mechanism 8, right incremental encoder 9, right current feedback module 10 and left current feedback module 11; control handle 1 is electrically connected to programmable controller PLC2; control signal of programmable controller PLC2 The output end is electrically connected to the signal input end of the proportional valve 3; the hydraulic output end of the proportional valve 3 is divided into two circuits, one is connected with the left hydraulic motor 4 and the left crawler running mechanism 5 in turn, and the other is connected with the right hydraulic motor 7 and the right crawler in turn The walking mechani...

specific Embodiment 2

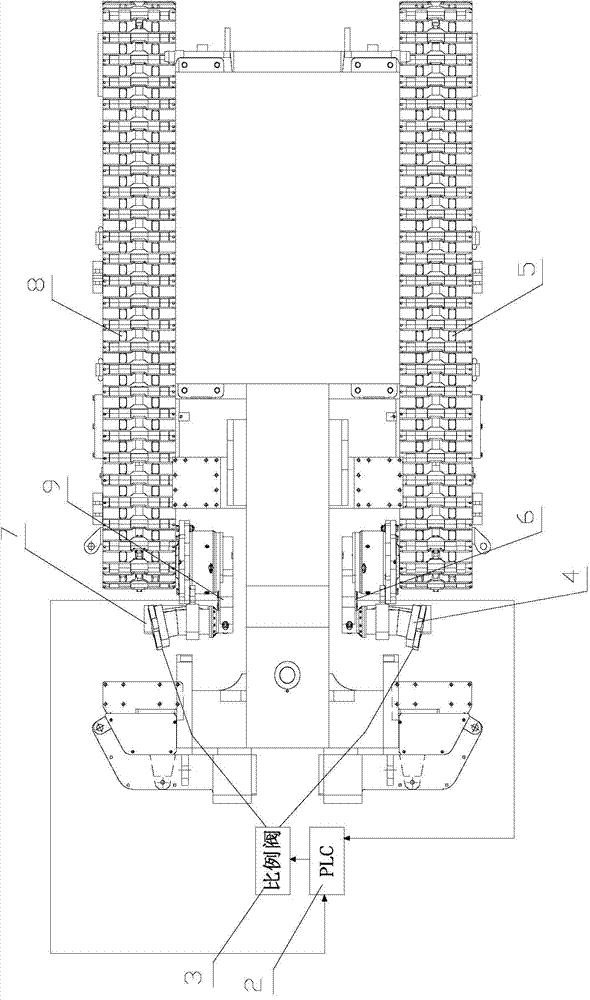

[0017] further combined with Figure 4 , an automatic control system for synchronous walking of the left and right crawlers, which includes a control handle 1, a programmable logic controller PLC 2, a proportional valve 3, a left hydraulic motor 4, a left crawler mechanism 5, a left incremental encoder 6, a right Hydraulic motor 7, right crawler walking mechanism 8, right incremental encoder 9, right current feedback module 10 and left current feedback module 11; control handle 1 is electrically connected to programmable controller PLC2; control signal of programmable controller PLC2 The output end is electrically connected to the signal input end of the proportional valve 3; the hydraulic output end of the proportional valve 3 is divided into two circuits, one is connected with the left hydraulic motor 4 and the left crawler running mechanism 5 in turn, and the other is connected with the right hydraulic motor 7 and the right crawler in turn The walking mechanism 8 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com