Novel aluminium oxide vertical activation roasting device and roasting method

A technology of alumina calcination, which is applied in the direction of vertical furnace, furnace type, process efficiency improvement, etc., can solve the problems of insufficient calcination of alumina pellets, waste of waste heat resources, large cooling energy consumption, etc., and achieve the reduction of shaft furnace Energy consumption, guaranteed combustion efficiency, sufficient gas-solid heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings.

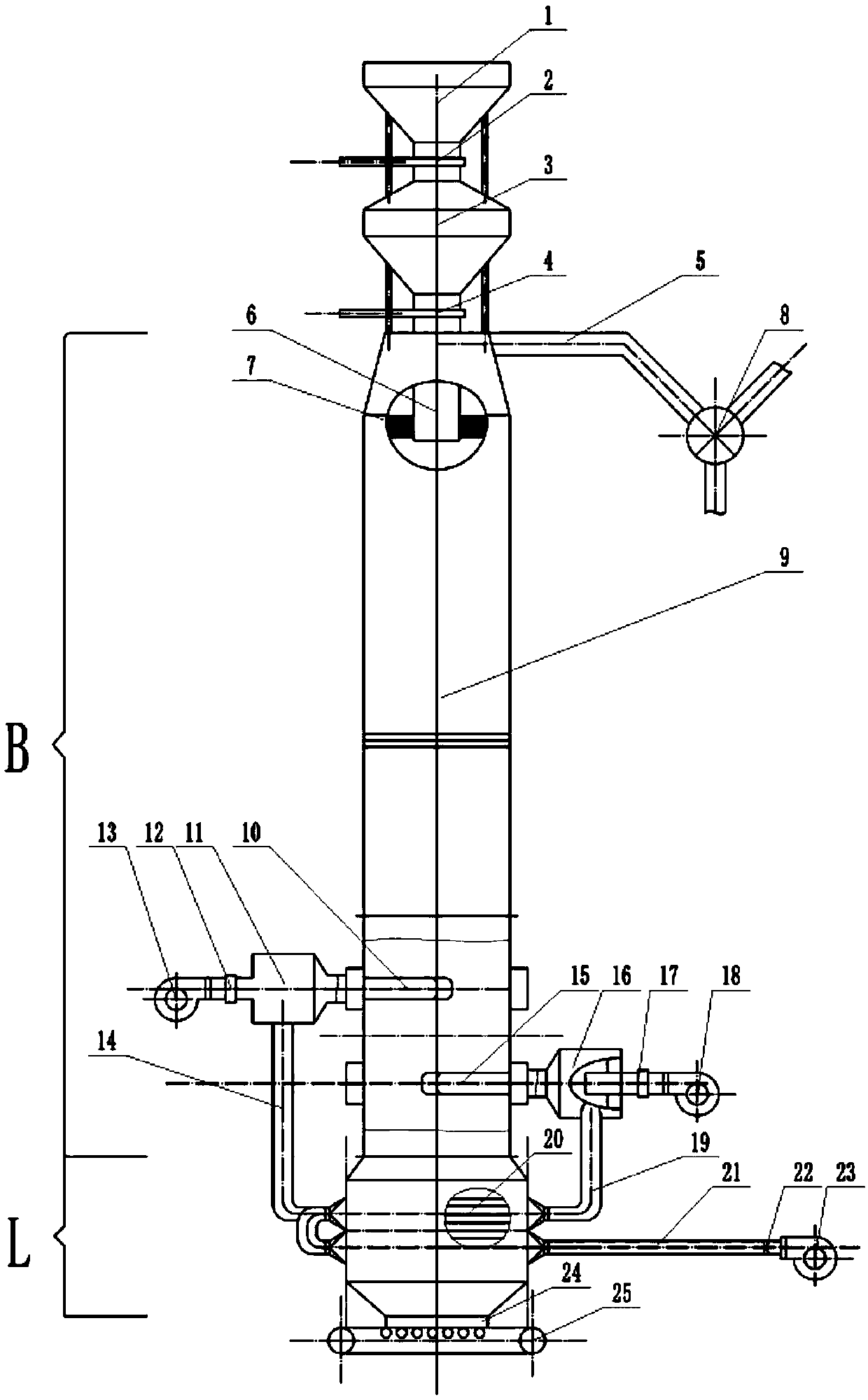

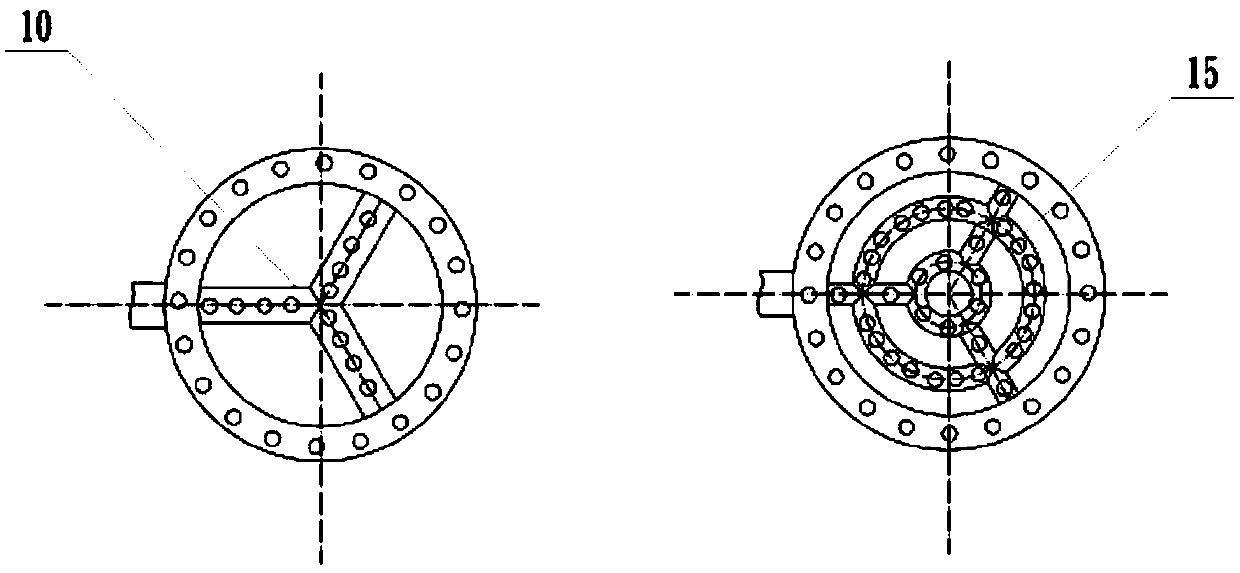

[0023] figure 1 It is a schematic diagram of the roasting device of the present invention, figure 2 It is a schematic diagram of the roasting air duct of the device of the present invention, as shown in the figure: a new type of alumina vertical activated roasting device, which mainly includes a feeding funnel 1, a gate valve A2, a temporary storage room 3, a gate valve B4, Vertical closed furnace body 9, self-excited dust collector 8, belt conveyor 25, fan 23 and pipelines connecting the above devices; the lower part of the feeding funnel 1 and the upper part of the temporary storage room 3 are equipped with a slide valve, and the feeding funnel Below 1 is the gate valve A2, below the temporary storage room is the gate valve B4, the feeding funnel 1 and the temporary sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com