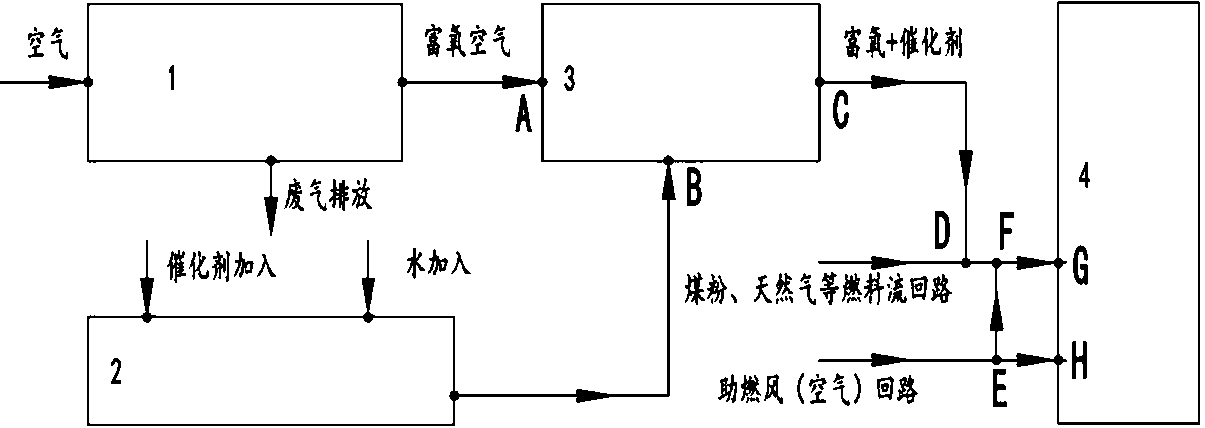

Furnace oxygen-enriched catalyzing combustion supporting method and device

A catalytic combustion and oxygen-enriching technology, which is applied in the direction of combustion methods, combustion using catalytic materials, indirect carbon dioxide emission reduction, etc., can solve equipment management, high maintenance costs, long construction period of oxygen equipment, high energy consumption of oxygen production, etc. , to achieve the effects of reducing excess air coefficient, changing combustion characteristics, and reducing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

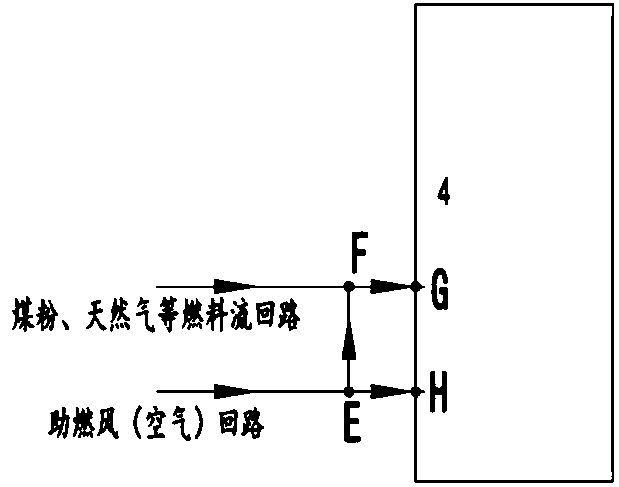

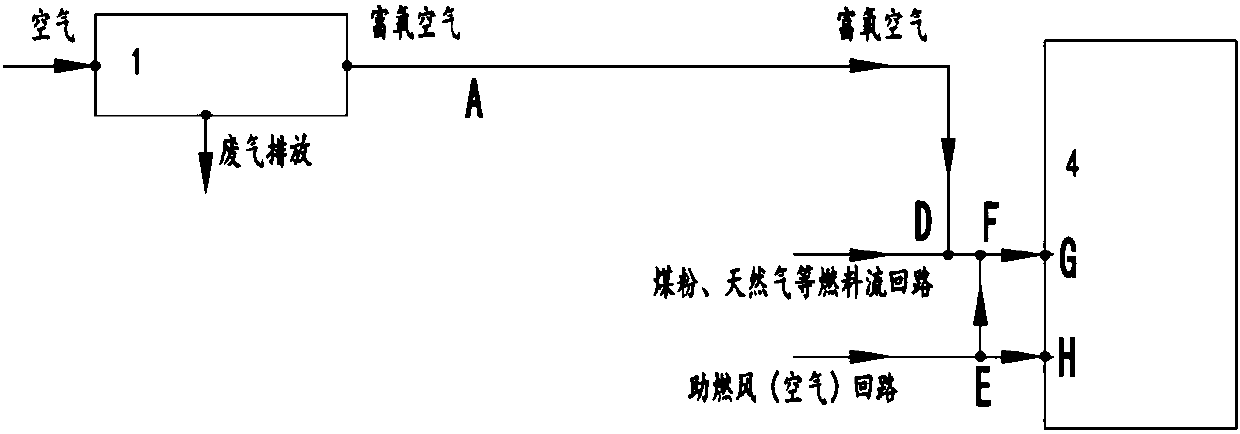

Method used

Image

Examples

Embodiment 1

[0065] A boiler that consumes about 267T of coal a day runs 360 days a year and works 24 hours a day. The calorific value of coal is 5024kcal / kg, the physical coal price is 700 yuan / T, the factory electricity fee is 0.67 yuan, the normal average load is 80%, and the natural production The steam is 72 tons, the standard coal consumption per unit of steam is about 111kg / T, and the hourly coal consumption is about 11.14T / h. When the plate-type membrane separator (produced by Shanghai Stuff Material Technology Co., Ltd., available on the market) uses membrane oxygen production as the oxygen source to perform partial oxygen-enriched combustion for the boiler, it will take about 6000m 3 / h, 30% oxygen-enriched, the power consumption is about 408KW, and the equipment investment is about 6 million yuan. The equipment maintenance and management costs are shown in the table below. It can achieve a coal-saving effect of about 6%, and it takes about 5 years to recover the investment. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com