Oxygen-enriched air mixed blowing combustion adjuvant boiler energy-saving method and equipment used thereby

An oxygen-enriched air and combustion-supporting agent technology, applied in the combustion method, combustion equipment, combustion air/fuel supply, etc., can solve the problem of not much improvement in cost and cost performance, achieve good comprehensive energy saving and emission reduction effect, and reduce ignition temperature. , easy to accept the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

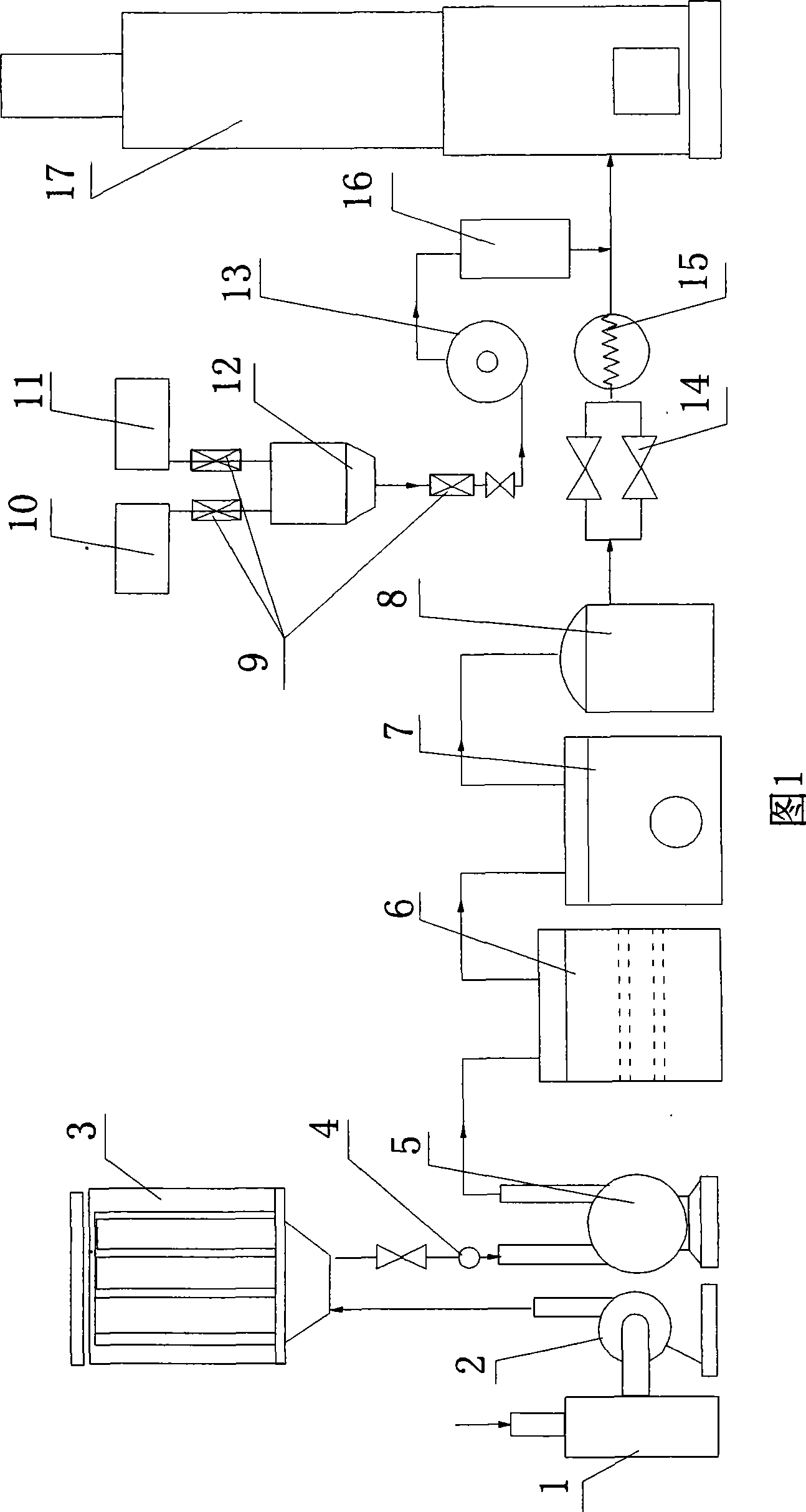

[0021] The energy-saving method of the oxygen-enriched air mixed-blown combustion-supporting agent boiler of the present invention and the equipment used therein are very simple and convenient to manufacture, and can be manufactured according to the drawings shown in the description. The air cleaner 1, blower 2, Membrane oxygen-enriched generator 3, vacuum gauge 4, vacuum pump 5, steam-water separator 6, air dryer 7, air regulator 8, reversing valve 9, air heater 10, combustion aid storage tank 11, water storage tank 12. Flow meter 13, liquid mixing tank 14, booster pump 15, combustion aid atomizer 16, and boiler 17 are all general chemical equipment or boiler combustion equipment.

[0022] Compared with the prior art, the energy-saving method of the oxygen-enriched air mixed blowing combustion-supporting agent boiler and the equipment used in the present invention have the characteristics of reasonable design, simple structure, easy processing, safety and reliability, and rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com