A retrofit method for energy saving and emission reduction to reduce the emission of nitrogen oxides from ddf decomposition furnace

A technology for energy saving, emission reduction and nitrogen oxides, which is applied in combustion methods, furnaces, and furnace components, etc., can solve the problems of increasing heat loss of chemical incomplete combustion, insufficient combustion of pulverized coal, and small volume of the decomposition furnace, and achieves a higher average rate. The effect of residence time, reduction of excess air coefficient, and improvement of burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

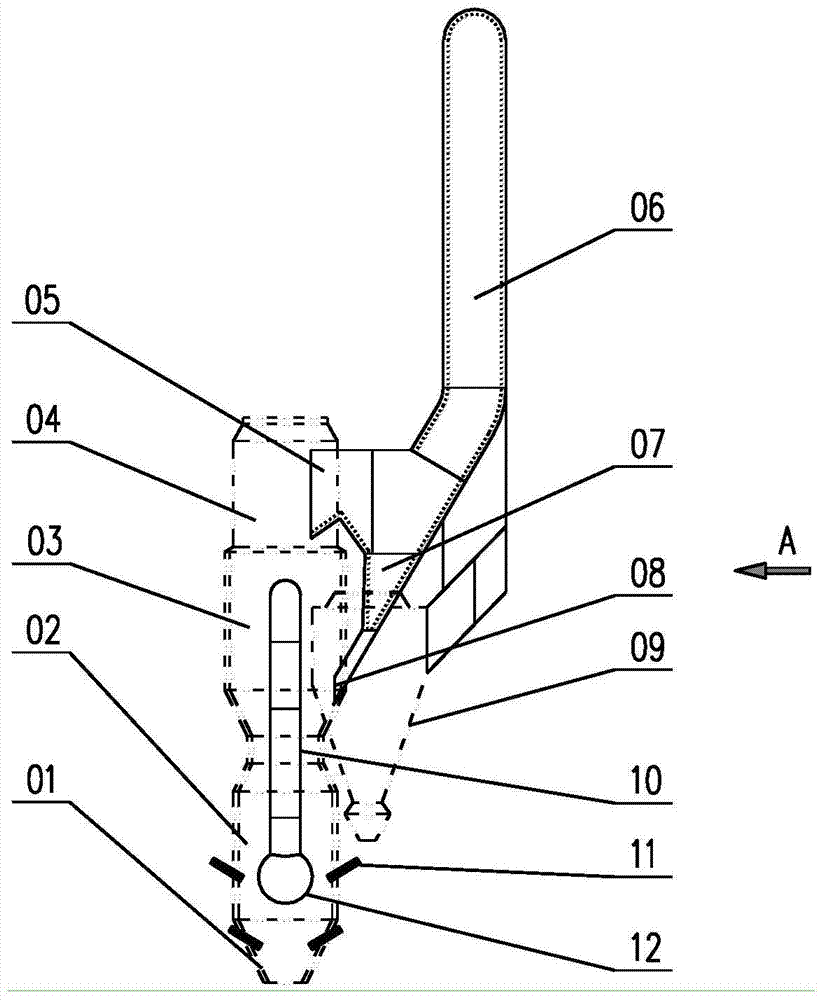

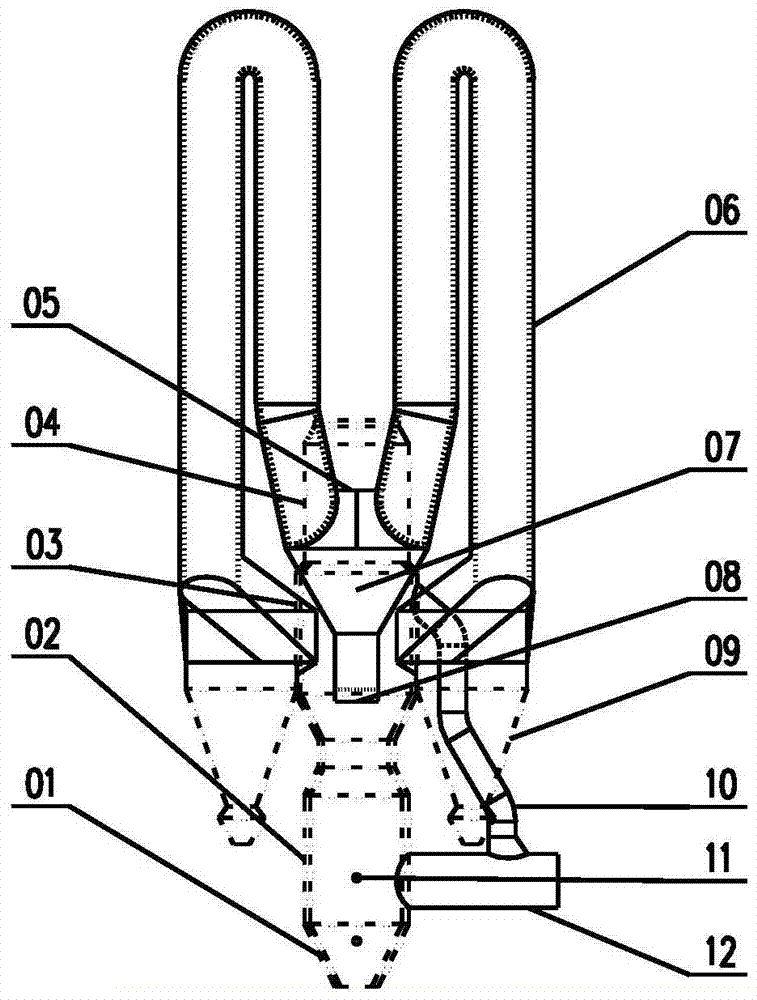

[0021] The volume of the existing calciner in a cement plant is only 300m 3 , when the output is 2100t / d, the residence time of the hot air in the calciner is only 2.0s, the connecting pipe from the calciner to the fifth-stage preheater is very short, and the daily output per unit capacity of the calciner is as high as 7.5t / m 3 d. It is recommended that the daily output per unit furnace capacity should not be higher than 4t / m 3d. The furnace capacity is obviously too small, which directly affects the insufficient combustion of pulverized coal in the calciner. After the transformation, it is planned to expand the calciner furnace by extending the combustion space to the outside of the frame, adding a horizontal confluence flue gas pipe and two symmetrically arranged external gooseneck pipes with a diameter of 2900mm when the calculation is performed at 2300t / d capacity, increasing the furnace capacity by 2.4 times to 720m 3 , the residence time of hot air is extended to 4.8s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com