Special heating furnace for joint coke production

A heating furnace and joint coke technology, which is applied to the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of energy waste, non-energy saving of heating furnace equipment, affecting the economic benefits of equipment, etc., and improve the operation efficiency. , Reduce the labor intensity of personnel, and the effect of intelligent control and adjustment of the heating furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

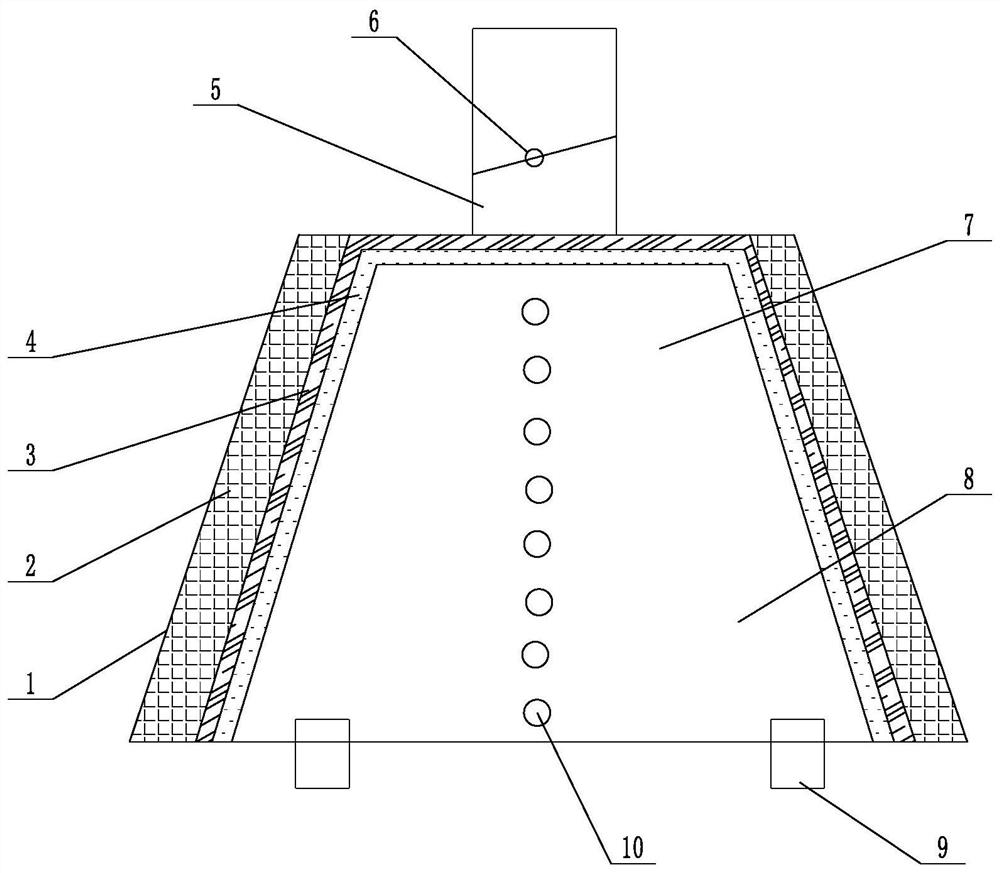

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the special heating furnace for joint coke production includes a furnace body 1, a chimney 5, a convection chamber 7, a radiation chamber 8, a burner 9 and a furnace tube 10, and the furnace body 1 is provided with a castable Furnace wall 2, the inner wall of furnace wall 2 is provided with dense ceramic lining 3, the surface of the lining is sprayed with high temperature resistant paint 4, the convection chamber 7 is located on the upper part of the radiation chamber 8, the burner 9 is located at the bottom of the furnace, inside the furnace body 1 Furnace tube 10 is provided.

[0022] The burners 9 are arranged symmetrically on both sides of the furnace tube 10 . The burner 9 is a low nitrogen burner. Use high-efficiency, low excess air coefficient, low NOx burner 9 to ensure that the flue gas is environmentally friendly

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com