Flue gas internal circulation tail gas incinerator burner

A tail gas incineration and burner technology, which is applied in the direction of gas fuel burners, burners, incinerators, etc., can solve the problems of incomplete combustion, NOx emission not up to standard, and high operating costs, so as to achieve direct air distribution and improve combustion efficiency , good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

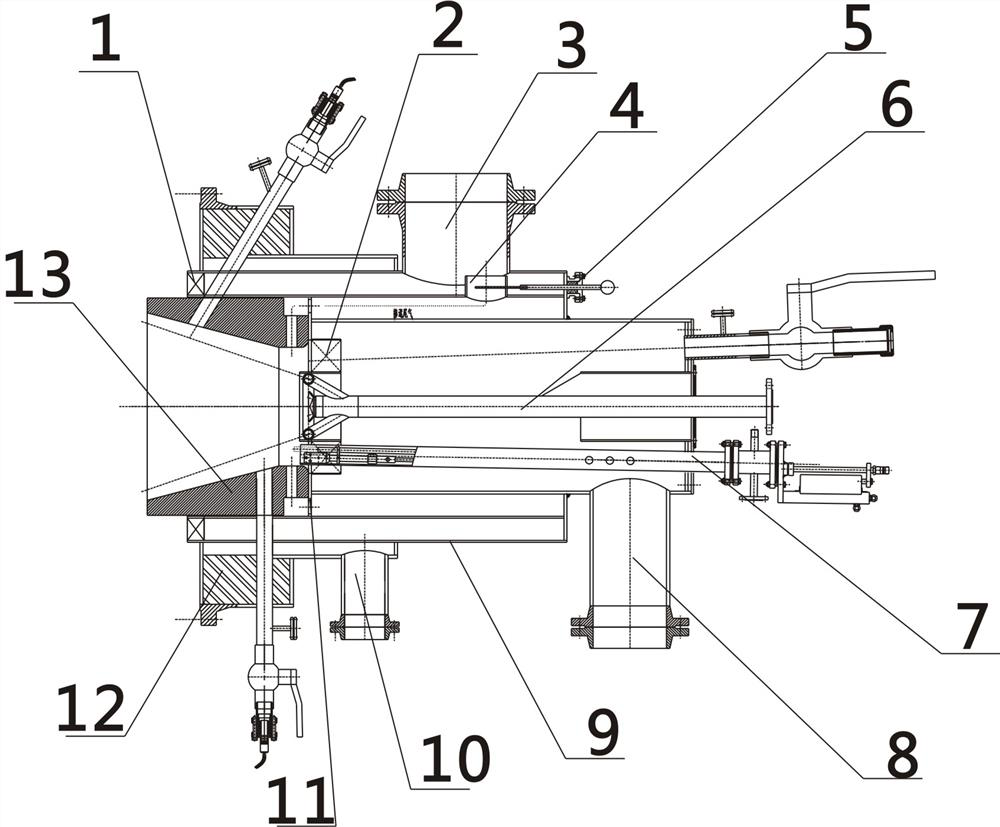

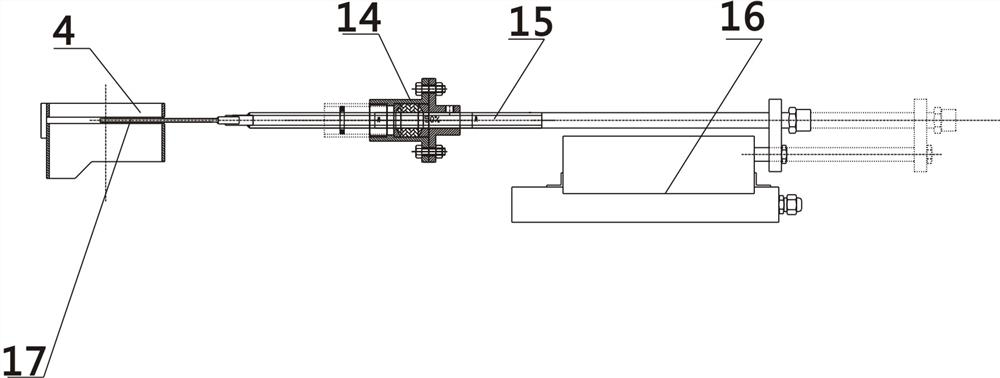

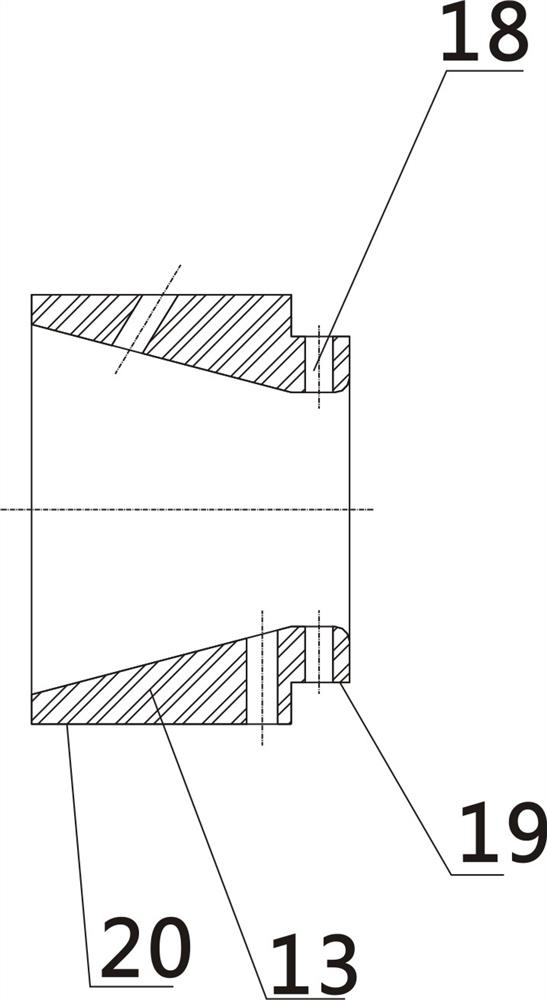

[0028] combined with Figure 1-6 The exhaust gas incinerator burner with internal flue gas circulation includes a burner housing 9, a brazier brick 13, a gas spray gun 6 and an exhaust gas mixing adjustment mechanism 5, and a brazier brick 13 is fixed inside the front end of the burner housing 9, The gas spray gun 6 is arranged at the center of the burner housing 9, and an ignition lamp 7 is fixed on the rear end flange of the burner housing 9;

[0029] The high-energy electric igniter installed inside the ignition lamp 7 has high electric spark energy and reliable ignition. The ignition rod is equipped with a propeller to realize automatic expansion and contraction. After the ignition is completed, the electrode head exits the high-temperature area to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com