Gas burner combustion injection device with dispersed free flame and low NOx

A technology of gas burner and injection device, applied in the directions of gas fuel burner, burner, combustion method, etc., can solve the problem of high local temperature of flame, and achieve the effects of increasing heat dissipation area, high combustion efficiency and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

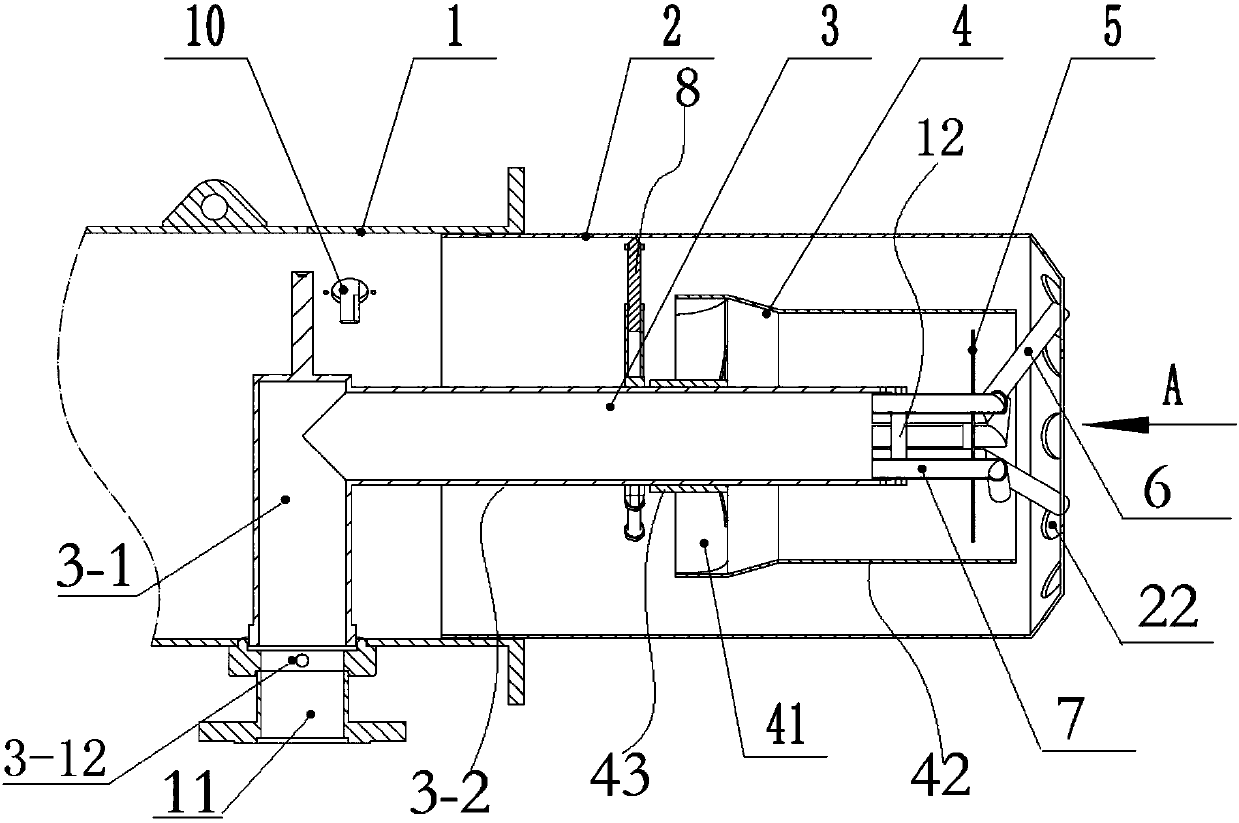

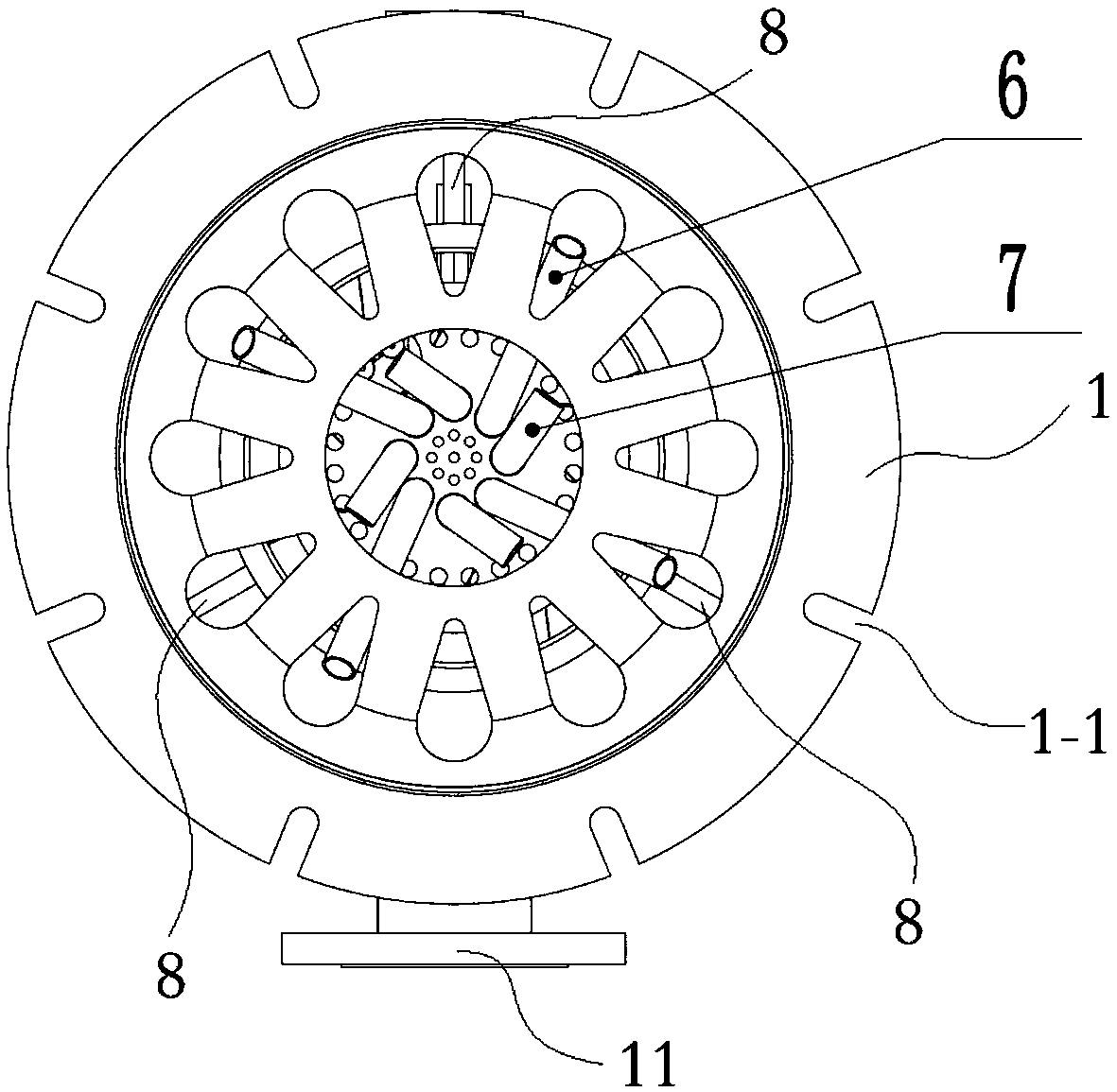

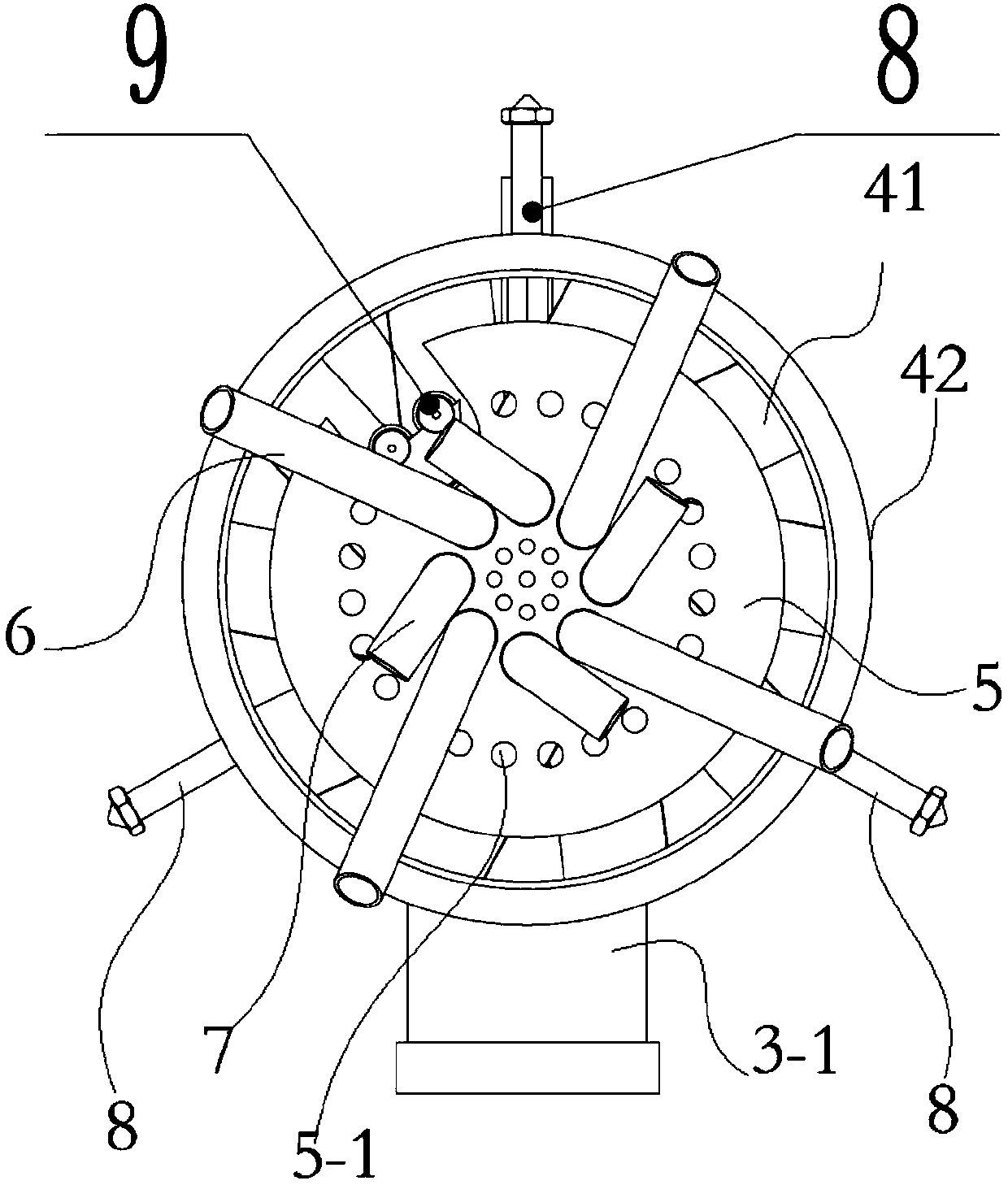

[0038] see Figure 1 to Figure 5 , a combustion injection device for a diffused free flame low NOx gas burner of the present invention, comprising a flame tube 2, an interface air pipe 11, an air intake pipe assembly 3 supplied by the interface air pipe, a fuel injection pipe, and two ignition needles 9; A number of fire outlets are arranged on the outlet end surface of the cylinder 2, and a blind section 23 is formed on the outlet end surface of the flame cylinder 2 outside the fire outlets, which is characterized in that:

[0039] It also includes rotating flange and primary air cylinder assembly;

[0040] Several fire outlets of the flame tube 2 are arranged in a petal shape, and the petal-shaped fire outlets include a central fire outlet 21, several outer ring fire outlets 22 evenly distributed on the periphery of the central fire outlet 21; The fire outlet 21, the outer ring fire outlet 22 and the blind section 23 form a petal shape, and the alternate arrangement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com