Gas Turbine Combustor Head Structure and Combustion Organization Method

A gas turbine and combustor technology, applied in the direction of combustion methods, combustors, continuous combustors, etc., can solve the problems of flat rise in nitrogen oxide emission levels, failure to meet emission standards, limited potential, etc., to reduce the possibility, Save cooling structure design and save cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

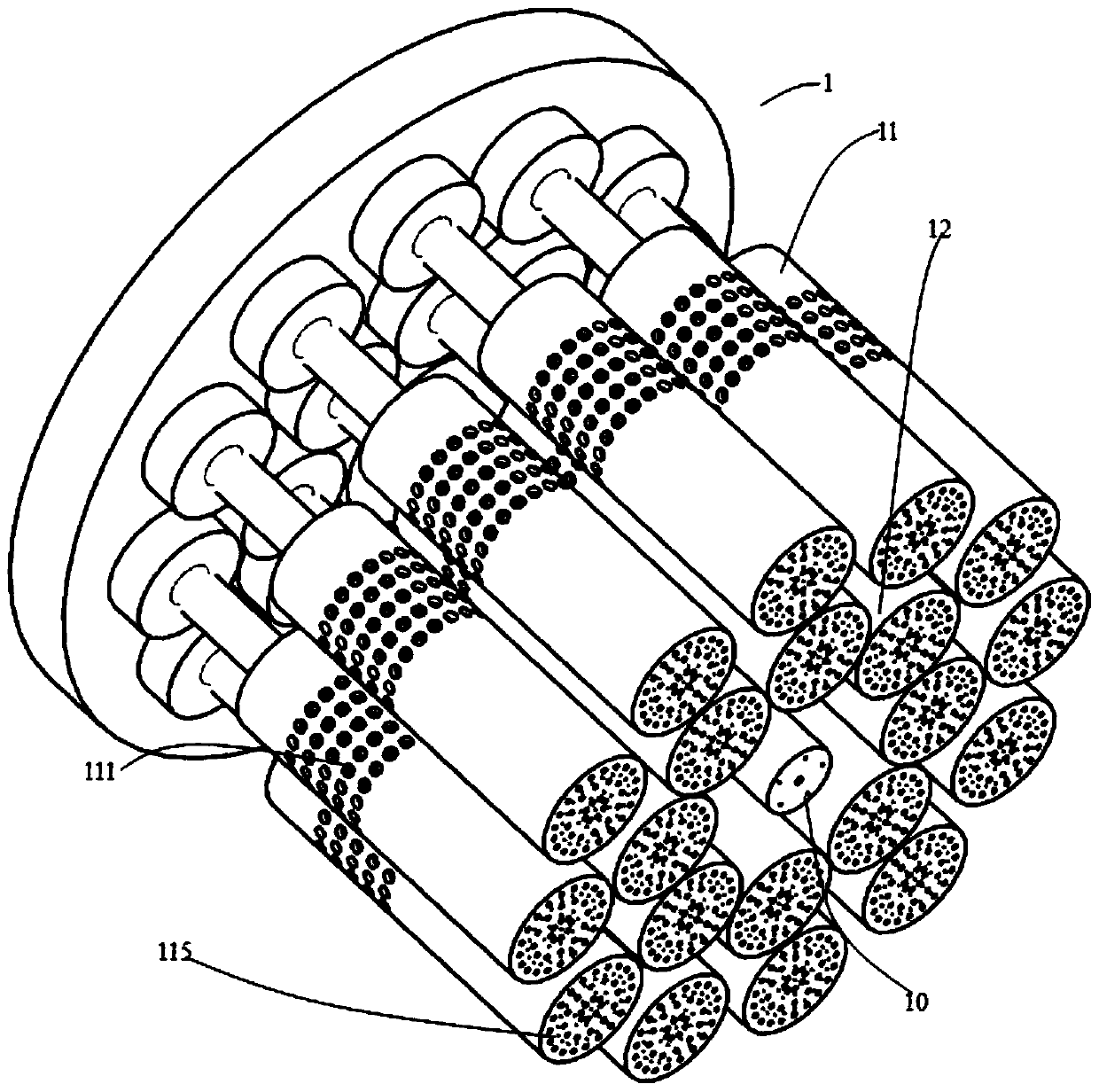

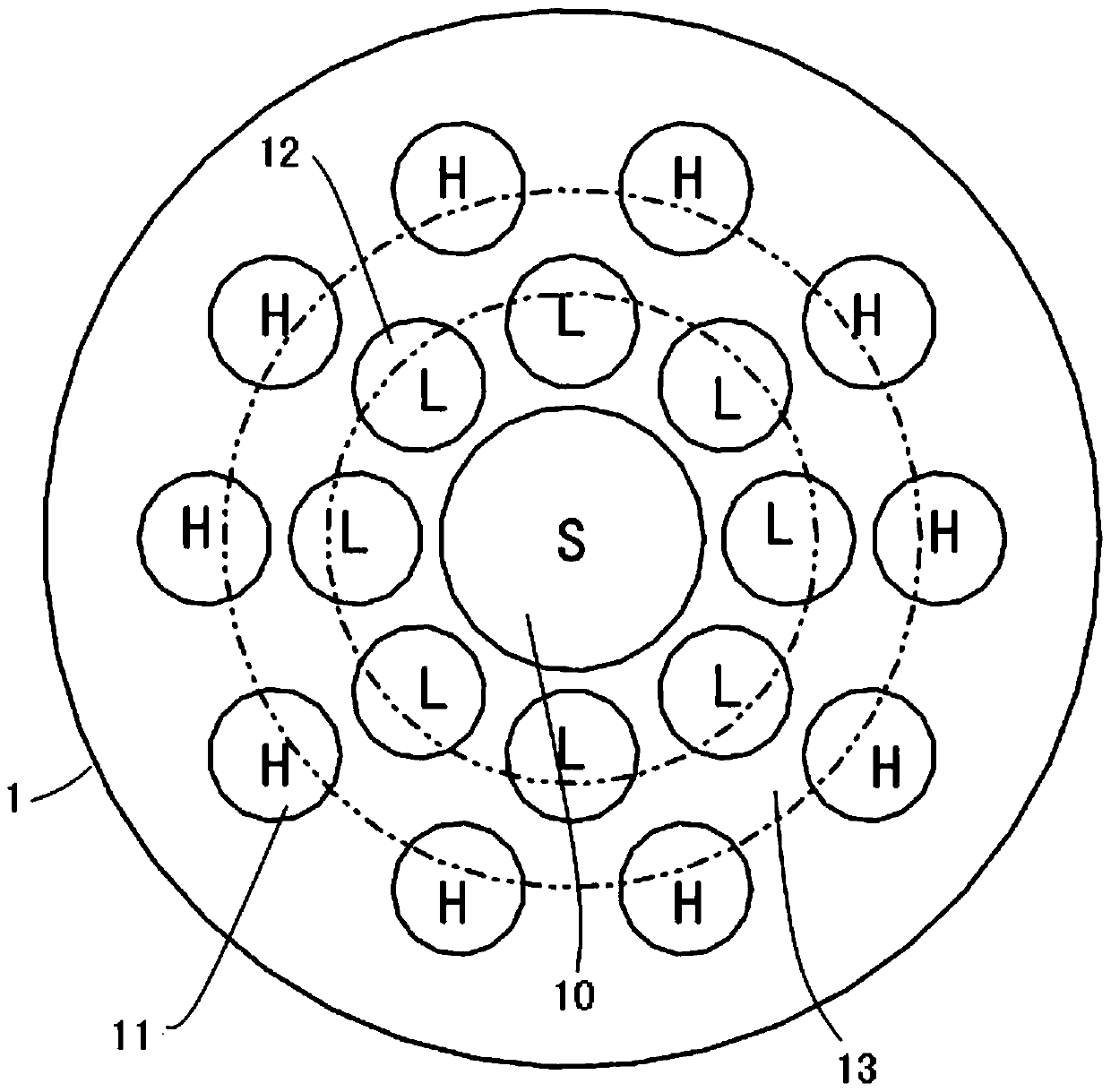

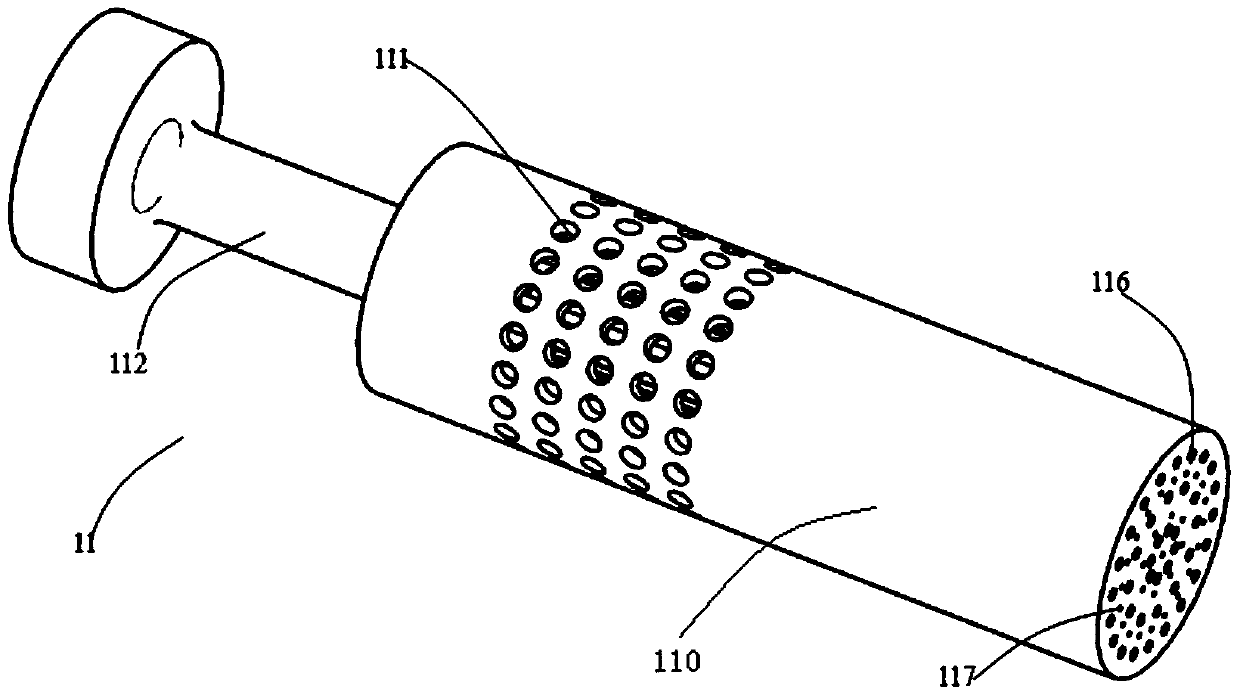

[0030] refer to Figures 1 to 6 As shown, the gas turbine combustor head structure of the present invention includes a head end plate 1 , a central swirl nozzle module 10 , a plurality of high-speed jet nozzle modules 11 and a plurality of low-speed jet nozzle modules 12 . The central swirl nozzle module 10 is installed on the head end plate 1 and is located at the center of the head end plate 1 . A plurality of high-speed jet nozzle modules 11 and a plurality of low-speed jet nozzle modules 12 are also mounted on the head end plate 1 and arranged around the central swirl nozzle module 10 to form an inner nozzle circle and an outer nozzle circle. The head end plate 1 is provided with a plurality of fuel intake passages for supplying fuel to the central swirl nozzle module 10 , the high-speed jet nozzle module 11 and the low-speed jet nozzle module 12 . Wherein, the average equivalent ratio of the high-speed jet nozzle module 11 is smaller than the average equivalent ratio of ...

Embodiment 2

[0040] The head structure of the gas turbine combustor in this embodiment includes a head end plate 1 , a central swirl nozzle module 10 , a plurality of high-speed jet nozzle modules 11 and a plurality of low-speed jet nozzle modules 12 . The central swirl nozzle module 10 is installed on the head end plate 1 and is located at the center of the head end plate 1 . A plurality of high-speed jet nozzle modules 11 and a plurality of low-speed jet nozzle modules 12 are also mounted on the head end plate 1 and arranged around the central swirl nozzle module 10 to form an inner nozzle circle and an outer nozzle circle. The head end plate 1 is provided with a plurality of fuel intake passages for supplying fuel to the central swirl nozzle module 10 , the high-speed jet nozzle module 11 and the low-speed jet nozzle module 12 . Wherein, the central swirl nozzle module 10, the high-speed jet nozzle module 11, and the low-speed swirl nozzle module 12 are all the same as in Embodiment 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com