Boron powder combustion heat value testing device

A testing device and calorific value technology, applied in the field of boron powder combustion calorific value testing device, can solve problems such as incomplete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is a test device for the calorific value of combustion of boron powder.

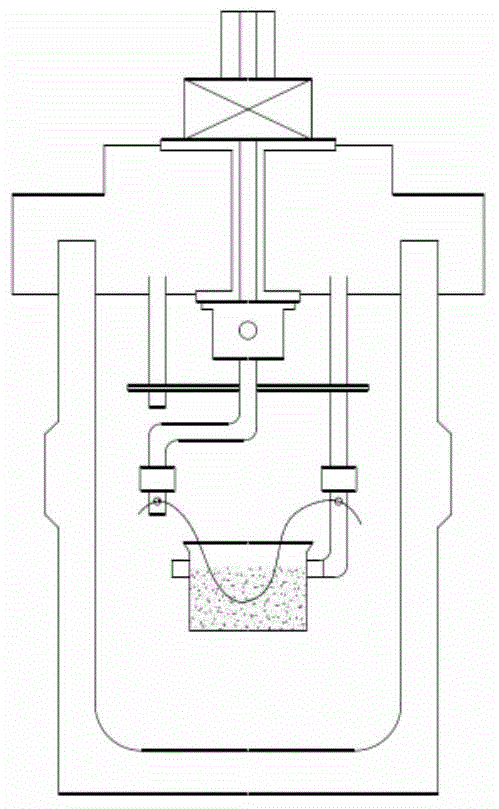

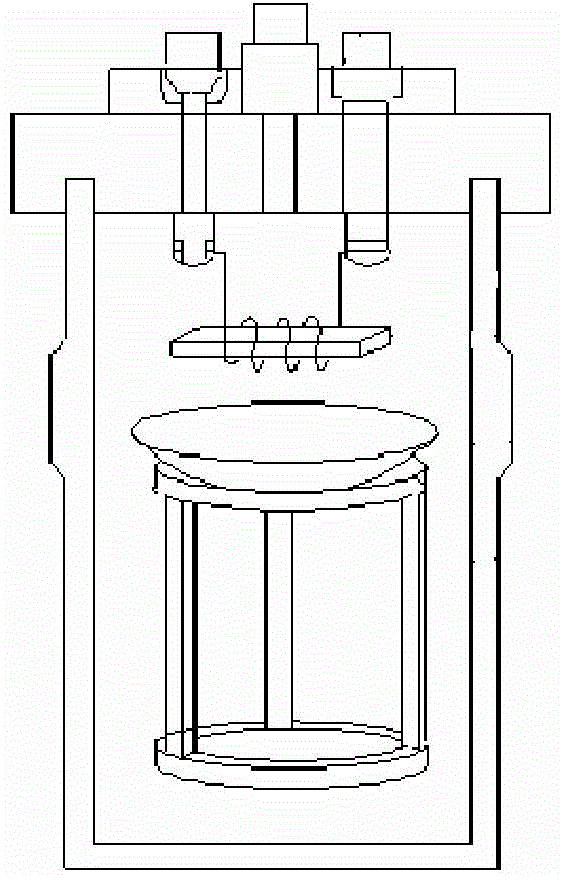

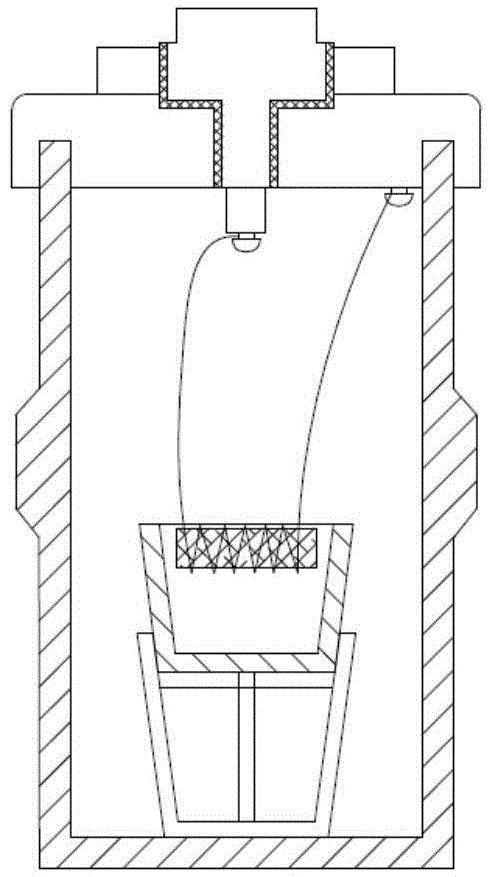

[0026] refer to Figure 1 ~ Figure 3 , The basic principle of using an oxygen bomb calorimeter to test the combustion calorific value of a sample is: the test system is composed of an oxygen bomb calorimeter, an ignition device, a temperature and temperature difference instrument, and a data acquisition computer. Wherein the oxygen bomb calorimeter is composed of an oxygen bomb, an inner cylinder, an outer cylinder, a stirrer, and a temperature sensor, and an appropriate amount of distilled water is installed in the inner cylinder and the outer cylinder. First calibrate the heat capacity of the test system, and then conduct the test. Connect the sample to the ignition wire and place it in the crucible of the oxygen bomb, fill the oxygen bomb with 2MPa oxygen, and then deflate it to the chamber pressure, repeat this twice, and then fill it with 2MPa oxygen to ensure that the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com