Premixing duty nozzle of combustion chamber of gas turbine

A technology for on-duty nozzles and gas turbines, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of high temperature and tempering of the nozzle wall surface, achieve low flame peak temperature, reduce NOx emissions, and facilitate application and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] On the premise of ensuring the combustion efficiency and performance of the combustion chamber, the invention can realize ultra-low nitrogen oxide emission in a wide load range by optimizing the nozzle on duty, especially can reduce the NOx emission of the combustion chamber under the low working condition of the combustion chamber , the premix duty nozzle has a compact structure and is suitable for the combustion of natural gas, coal-to-synthesis gas and other low-to-medium calorific value synthesis gases.

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

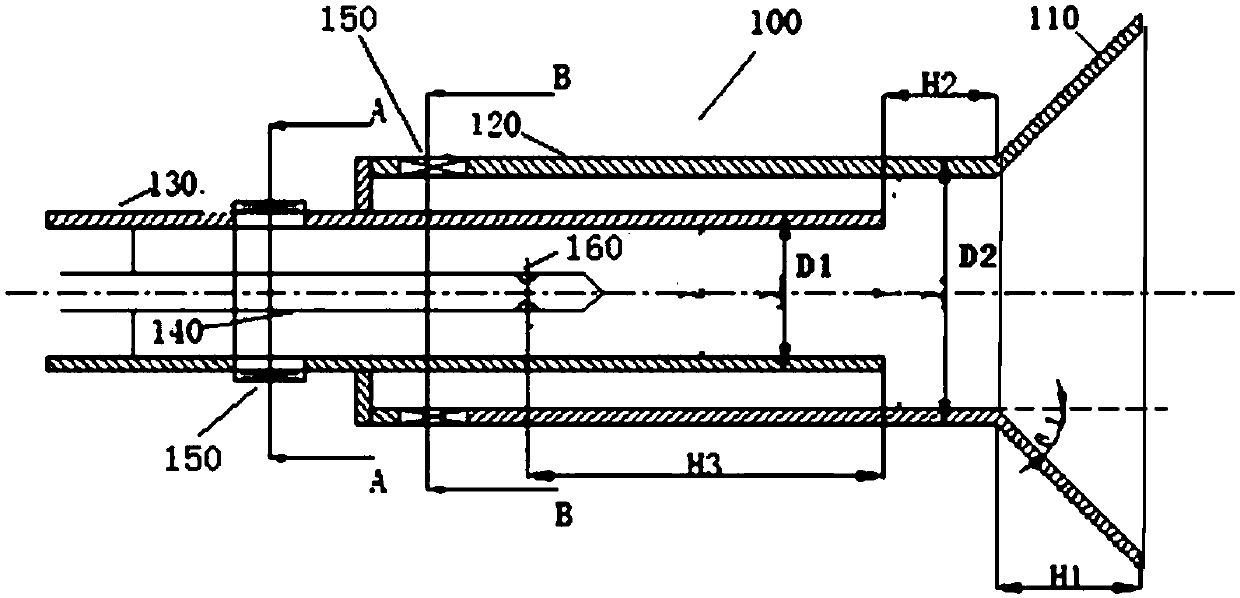

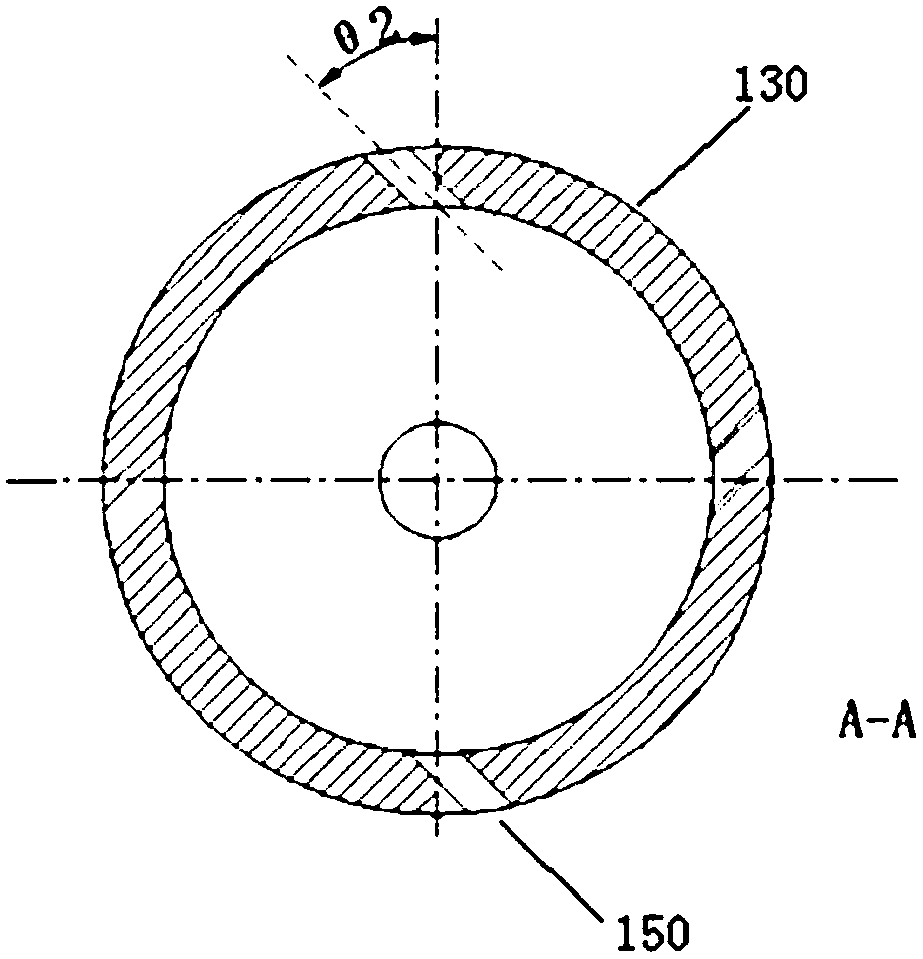

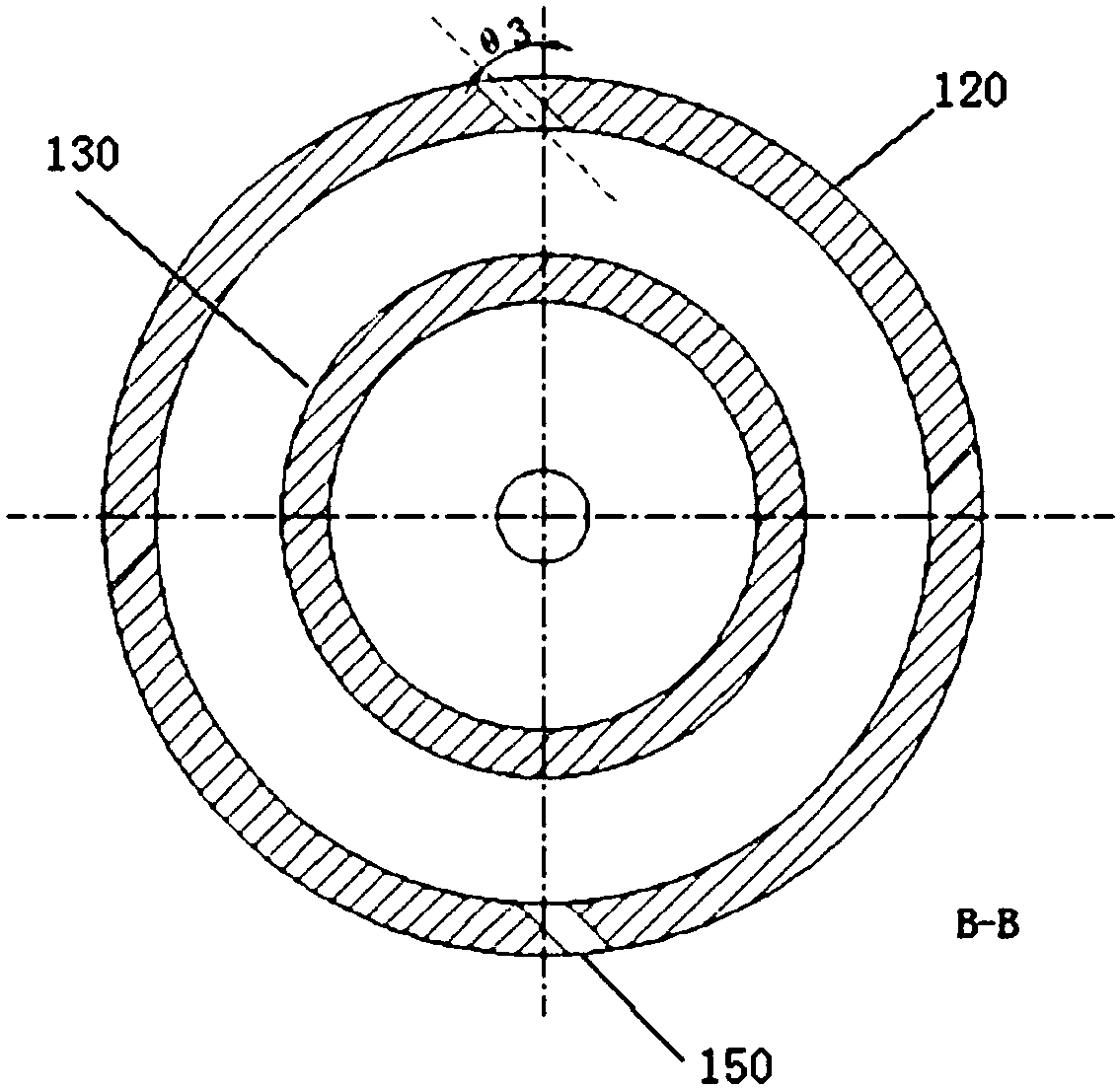

[0034] see Figure 1-Figure 3 , the embodiment of the present invention provides a premix duty nozzle 100 , including: a cone 110 , an outer swirl passage 120 , an inner swirl passage 130 and a duty fuel nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com