Method for preparing cadmium selenide quantum dots by using microbial cells

A technology of microbial cells and quantum dots, applied in the direction of bacteria, fermentation, etc., can solve the problems affecting the uniformity and harshness of the product, and achieve the effect of low synthesis cost, simple method and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

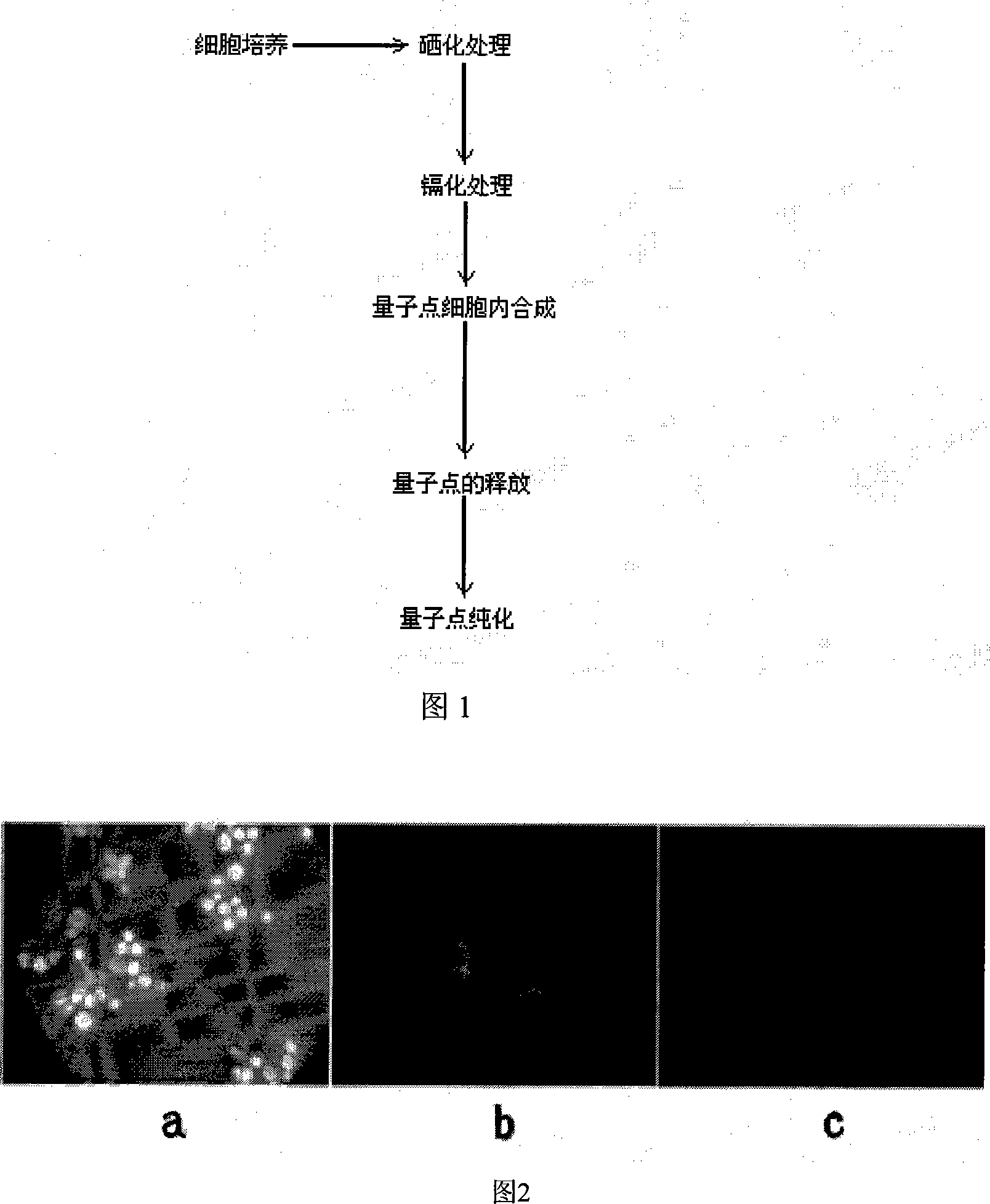

Method used

Image

Examples

Embodiment 1

[0059] 1. Culture of Yeast Cells

[0060] First, inoculate a single colony of Saccharomyces cerevisiae into YPD medium, culture with shaking at 30°C for 24 hours; set aside.

[0061] 2. Selenization treatment of Saccharomyces cerevisiae cells

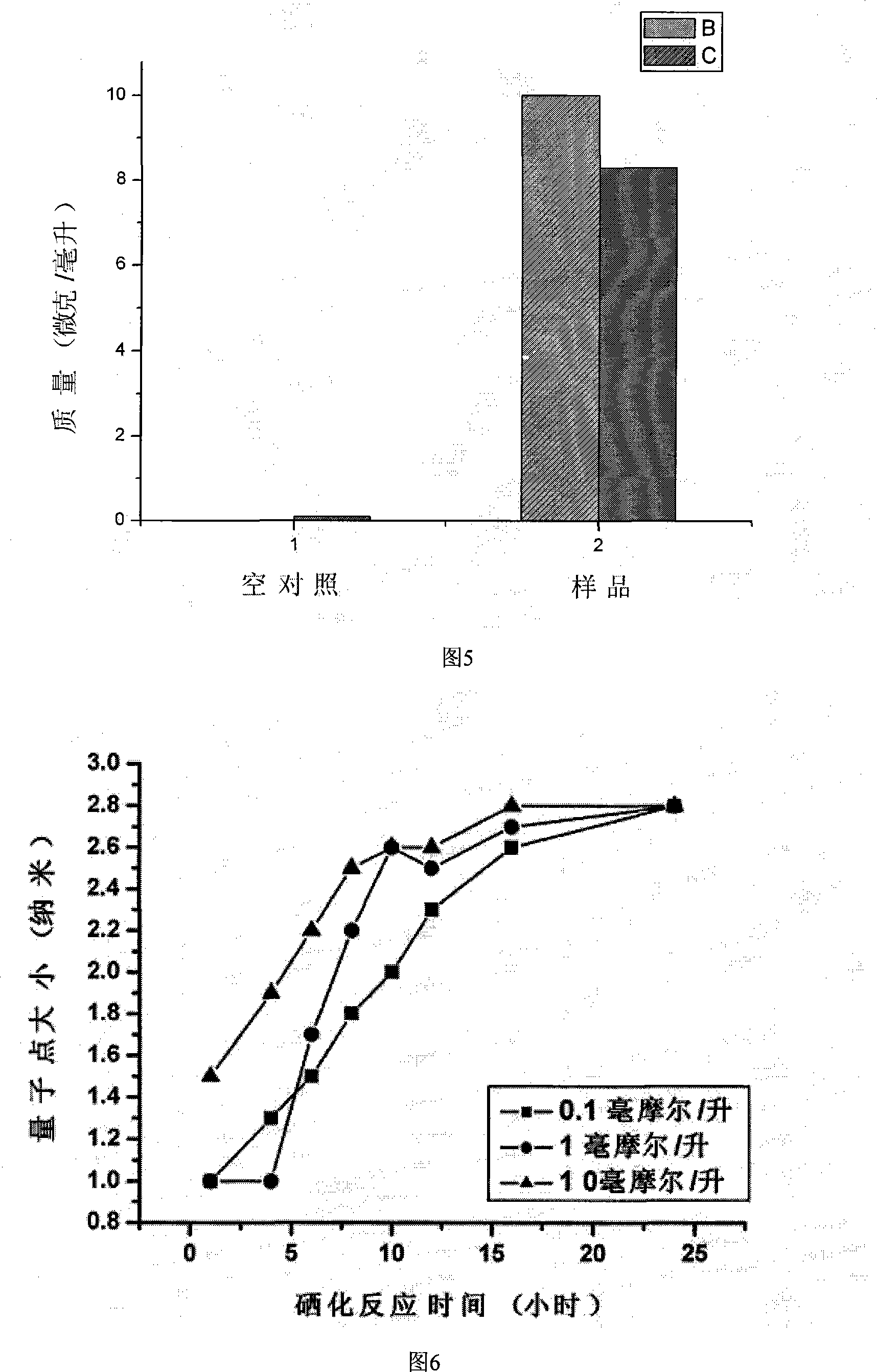

[0062] 0.05 milliliters, 0.5 milliliters, and 5 milliliters of Na2SeO3 (100 mg / liter) solutions were respectively added to three bottles of Saccharomyces cerevisiae cell suspension obtained in step 1 (50 milliliters of cell suspension in each bottle), and cultured with shaking at 30°C for 0-25 Hour.

[0063] 3. The synthesis of cadmium treatment of cells and the synthesis of CdSe quantum dots in cells

[0064] The cell suspension obtained after step 2 was centrifuged at 8000 rpm for 3 minutes, and the supernatant was discarded. and resuspended in fresh YPD medium. Then add 0.5 ml of 100 mmol / L CdCl2 solution, and shake at 30° C. for 12 hours.

[0065] 4. Extraction of intracellular CdSe quantum dots

[0066] The cell suspension ob...

Embodiment 2

[0070] 1. Yeast cell culture

[0071] First, inoculate a single colony of Saccharomyces cerevisiae into YPD medium, culture with shaking at 30°C for 24 hours; set aside.

[0072] 2. Selenization treatment of Saccharomyces cerevisiae cells

[0073] 0.5 ml of Na2Se03 (100 mg / L) solution was added to 50 ml of Saccharomyces cerevisiae cell suspension obtained in step 1, and cultured with shaking at 30° C. for 24 hours.

[0074] 3. The synthesis of cadmium treatment of cells and the synthesis of CdSe quantum dots in cells

[0075] The cell suspension obtained after step 2 was centrifuged at 8000 rpm for 3 minutes, and the supernatant was discarded. and resuspended in fresh YPD medium. Then add 0.05 milliliters, 0.5 milliliters and 5 milliliters of CdCl2 solution (concentration is 100 mmol / liter) respectively, and shake at 30 DEG C for 0-40 hours.

[0076] 4. Extraction of intracellular CdSe quantum dots

[0077]The cell suspension obtained in step 3 was centrifuged at 8000 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com