Method of manufacturing a supercapacitor

A technology of supercapacitor and manufacturing method, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of increased internal resistance of capacitors, capacity attenuation, easy delamination of coatings and corroded aluminum foils, and weak coating adhesion. To achieve the effect of high density, high energy density, high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

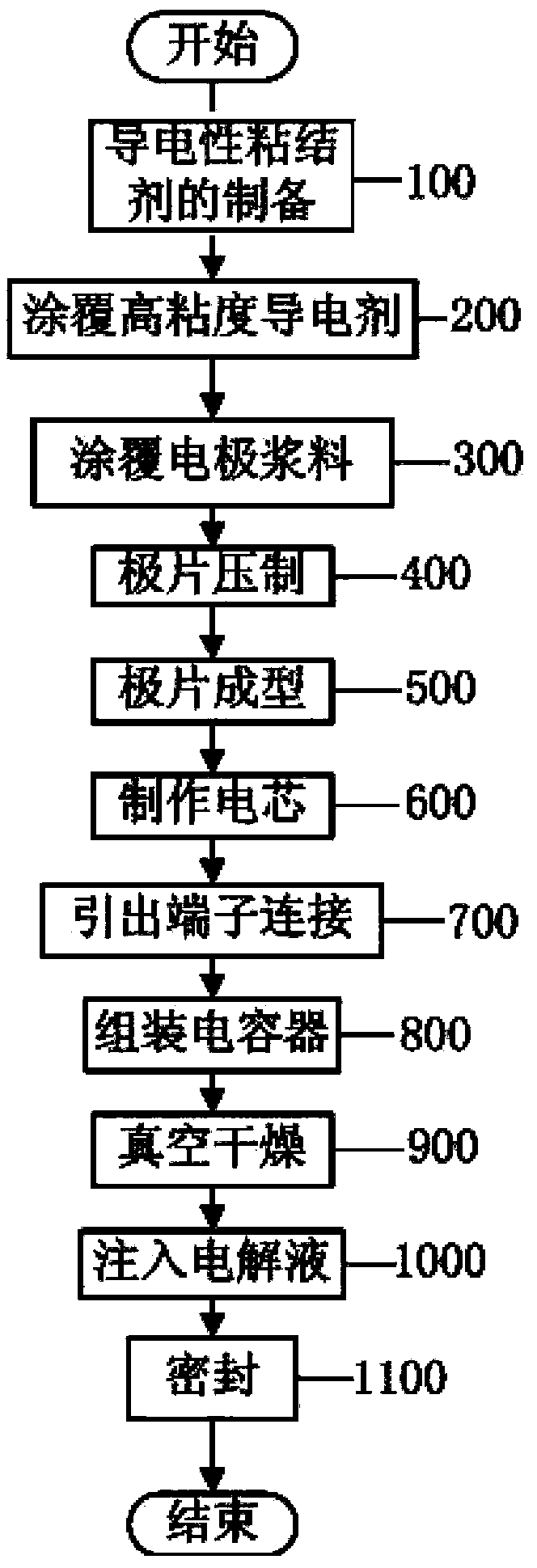

[0060] Such as figure 1 The illustrated embodiment is a method of manufacturing a supercapacitor, comprising the steps of:

[0061] Step 100, preparation of conductive binder: according to the ratio of deionized water and carboxymethylcellulose binder mass ratio of 50:1, put deionized water and carboxymethylcellulose binder into the mixer Stir in the storage tank for 40 minutes to fully integrate the deionized water and carboxymethyl cellulose binder;

[0062] According to the mass ratio of graphene and the carboxymethylcellulose binder in the storage tank is the ratio of 1:0.5, graphene is dropped in the storage tank of stirrer, and stir 40 minutes;

[0063] According to the mass ratio of conductive carbon black and the carboxymethyl cellulose binder in the storage tank is the ratio of 25: 1, drop into conductive carbon black in the blender,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com