Environmental protective diesel oil, and preparation method

A diesel and environmental protection technology, applied in the field of environmentally friendly diesel and its preparation, can solve the problems of difficult to popularize and use water-mixed diesel, poor stability of emulsified diesel, influence on atomization and combustion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

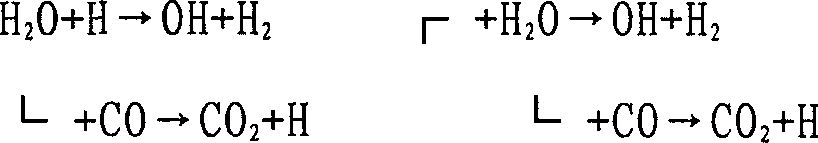

Method used

Image

Examples

Embodiment 1

[0029] The environmentally friendly diesel is composed of the following components by weight: 14 parts of zero diesel, 22 parts of water, 23 parts of vegetable oil, 10 parts of methanol, 25 parts of kerosene, and 6 parts of additives to synthesize the environmentally friendly diesel of the present invention.

Embodiment 2

[0031] The composite additive is composed of the following components by weight: 2.62 parts of Triton X-100 (OP emulsifier), 1.732 parts of ethanolamine, 14.51 parts of sodium hydroxide, 53.008 parts of ammonia (99.5%), and 5.57 parts of tincture , 20.36 parts of isopropanol, 2.0 parts of water, 0.2 parts of cetane number.

Embodiment 3

[0032] Embodiment 3 (preferred embodiment)

[0033] The environmentally friendly diesel is composed of the following components by weight: 16.5 parts of diesel, 24.2 parts of vegetable oil, 10.7 parts of methanol, 19 parts of water, 25 parts of kerosene, and 4.6 parts of compound additives to synthesize the environmentally friendly diesel of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com