Novel energy-saving gas burner

A gas burner, a new type of technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient combustion, low power, floating fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

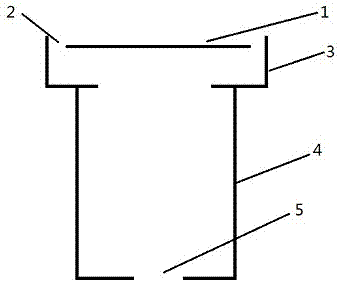

[0006] The gas burner has a round pipe gas supply pipe 4 that is uniform up and down. The lower part of the gas supply pipe 4 is an air inlet 5. The upper end of the gas supply pipe 4 is placed with three flamethrowers 3 that are tangential to the diameter of the garden. The flamethrower top plate 1 is located on the flamethrower 3. In the middle position, there is a groove 2 between the flamethrower 3 and the top plate 1 of the flamethrower, and the groove 2 communicates with the air inlet 5 up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com