Welding and cutting gas and preparation method thereof

A technology for welding and cutting gas and natural gas, applied in gas fuel, petroleum industry, fuel and other directions, can solve problems such as hidden safety hazards, corrosion of steel cylinders, easy explosion, etc., and achieve the effects of cost saving, low energy consumption and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

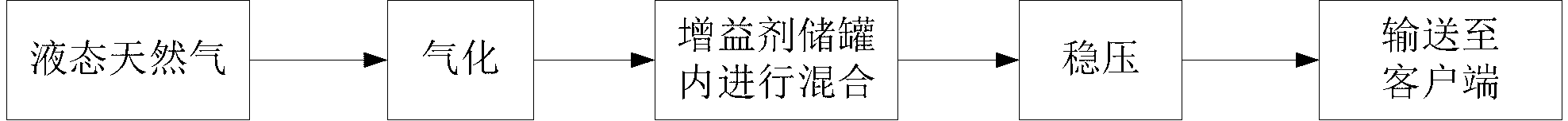

[0032] The consumption of welding and cutting gas is 500m 3 Customers within / d can use the liquefied natural gas stored in the Dewar tank to prepare the welding and cutting gas. Since the dewar tank has its own pressurization device and gasification device, the stored liquid natural gas can be vaporized without an additional vaporizer, and then the vaporized natural gas and gain agent are mixed to form welding and cutting gas. figure 1 A schematic flow chart showing the preparation of the welding and cutting gas from the liquefied natural gas stored in the Dewar tank is shown. Such as figure 1 As shown, the gasification device of the Dewar tank is used to gasify the liquefied natural gas, and the gasified natural gas is discharged through its gas phase outlet, and the gas phase outlet is connected to the bottom of the gain agent storage tank through a hose, so that the natural gas passes through The bottom of the buff tank enters the buff tank and escapes through the liquid...

Embodiment 2

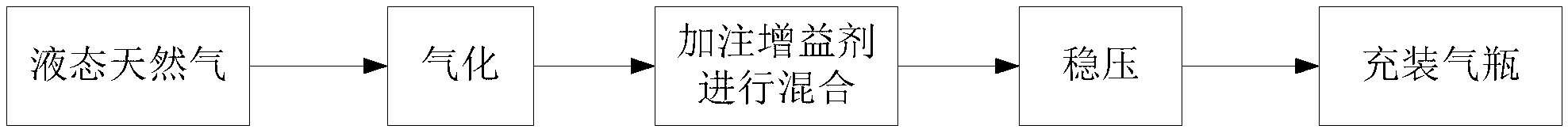

[0035] For the current acetylene plant, the welding gas can be prepared by pressurizing and gasifying the liquefied natural gas in the natural gas storage tank and mixing it with the gain agent, and then filling the welding gas into the gas cylinder and selling it to replace the original production of acetylene . figure 2A schematic flow chart showing the preparation of the welding and cutting gas by using the liquefied natural gas stored in the natural gas storage tank and filling the gas cylinder is shown. Such as figure 2 As shown, the liquefied natural gas in the natural gas storage tank is transported to the high-pressure vaporizer by the high-pressure cryogenic pump for gasification, and the outlet of the high-pressure vaporizer is connected to the mixing buffer tank through the delivery pipeline. The gain agent is injected into the delivery pipeline according to a certain proportion, and mixed with natural gas to form welding and cutting gas. The obtained welding an...

Embodiment 3

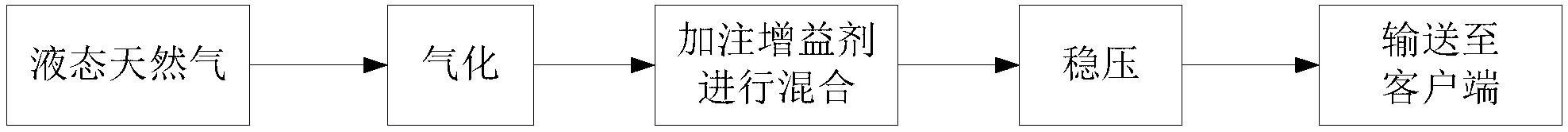

[0039] The consumption of welding and cutting gas is 1500m 3 Customers with / d and above can prepare welding and cutting gas by gasifying the liquefied natural gas in the natural gas storage tank and mixing it with a gain agent, and then adopt the centralized gas supply mode to transport the welding and cutting gas to each workshop through the main gas pipeline or working platform. image 3 A schematic flow chart showing the preparation of the welding and cutting gas by using the liquefied natural gas stored in the natural gas storage tank and performing centralized gas supply. Such as image 3 As shown, the liquefied natural gas in the natural gas storage tank is transported to the vaporizer for vaporization, and the outlet of the vaporizer is connected to the mixing buffer tank through a transmission pipeline. The gain agent is injected into the delivery pipeline according to a certain proportion, and mixed with natural gas to form welding and cutting gas. The obtained we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com