Water-heat-power cogeneration system and method based on seawater desalination and cascade energy consumption

A technology for cogeneration and plant power system, which is applied in steam application, combined combustion mitigation, steam engine installation, etc. It can solve problems such as prolonging the response time of power grid dispatching commands, increasing the complexity of power grid dispatching, and limiting the economy of external steam supply. , to achieve the effect of reducing raw water intake, easy expansion, and less difficulty in project implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039]Example 1

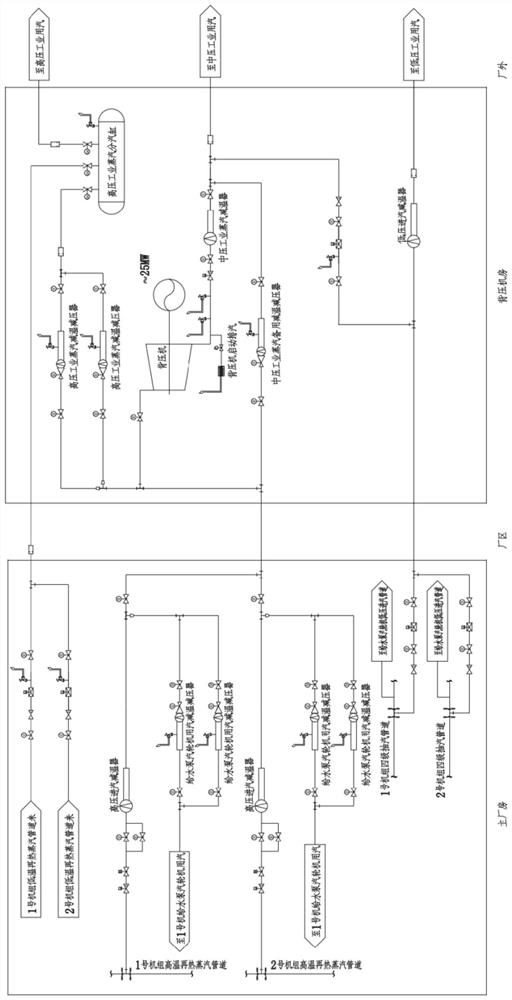

[0040]In a typical embodiment of the present disclosure, such asFigure 1 - Figure 2As shown, a water-thermal electric cogeneration system based on seawater dilution and steps can be proposed.

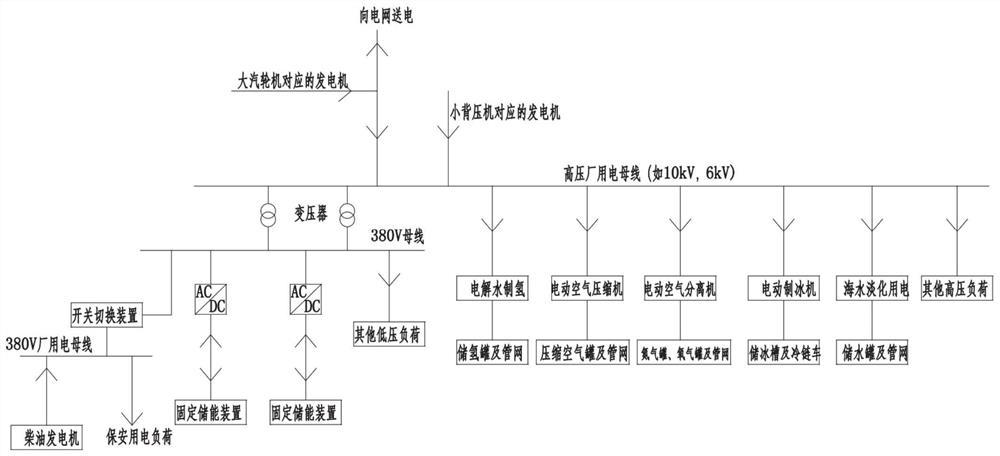

[0041]It mainly includes seawater dilution system, back pressure machine and reduced pressure reduction bypass system, energy storage and frequency modulation system and plant electrical system;

[0042]Among them, two types of fuelization methods are provided for seawater dilution systems;

[0043]One is the heat-resistant seawater, using low temperature and multi-effect seawater dilution devices, the raw water inlet is connected to the circulating cooling water drain of the seawater secondary circulation cooling tower;

[0044]In order to reduce the amount of water, the evaporation system of the low temperature and multi-effect seawater devices is used to cool the closed circulation cooling system, and the air-cooling device is provided to provide cooling circulating water for low temper...

Example Embodiment

[0123]Example 2

[0124]In another typical embodiment of the present disclosure, such asFigure 1 - Figure 2As shown, a water-thermal cogeneration method based on seawater dilution and step can be given.

[0125]Include the following steps:

[0126]Powering from the plant electrical system Through the drainage of the secondary circulating cooling tower by dilution equipment, it is dense water and output;

[0127]The steam of the turbine generator set is taken for step-by-step utilization, which outputs high, medium, low voltage industrial steam. Among them, the steam extracted from the high pressure cylinder is refined after the boiler, and then takes a portion or all of the high-temperature and hot steam input back pressure. Power generation, and output medium-voltage industrial steam; two unit work sections are connected to the back pressure, and the back pressure is incorporated into the factory, and power is powered by the sea water;

[0128]Plant electrical network connection gas system and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com