Auxiliary engine tracking power source system for power plant

A technology for power plants and generators, applied in electrical components, energy industry, circuit devices, etc., can solve the problems of unit operation safety threats, complicated inverter maintenance, and high operating failure rates, achieving superior energy-saving effects, reducing length and high voltage. The number of switching intervals, the effect of a simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

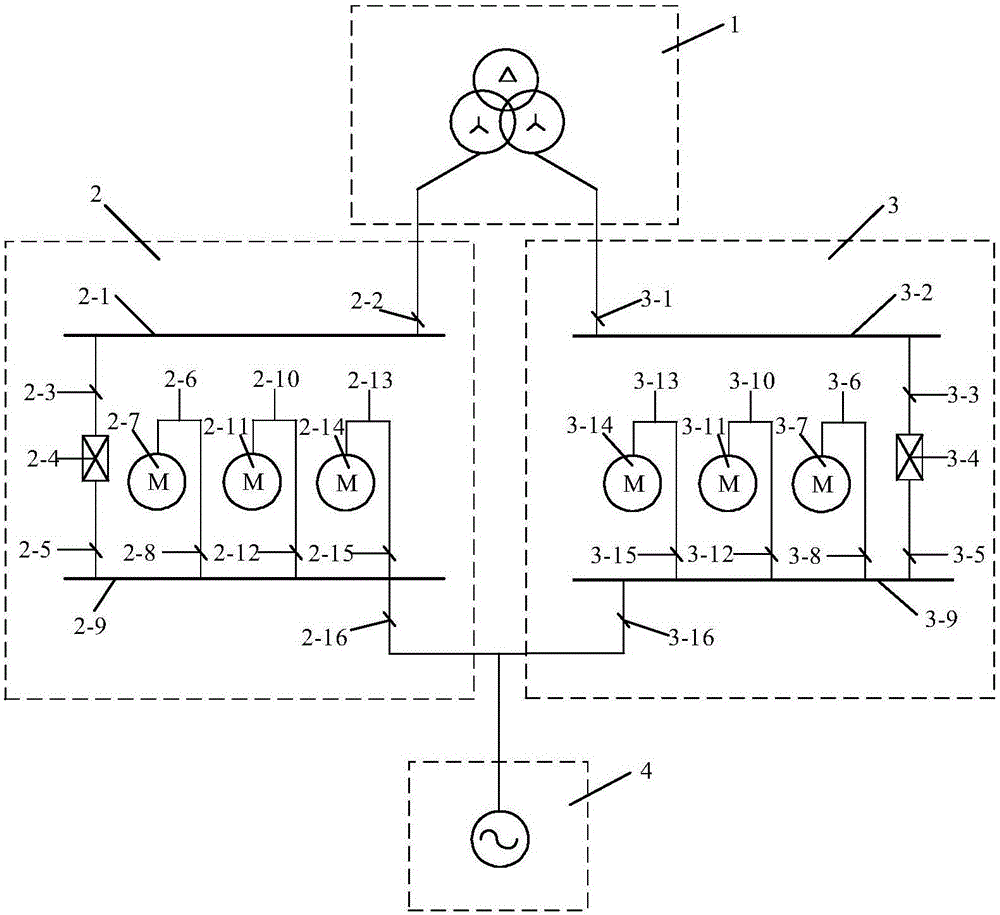

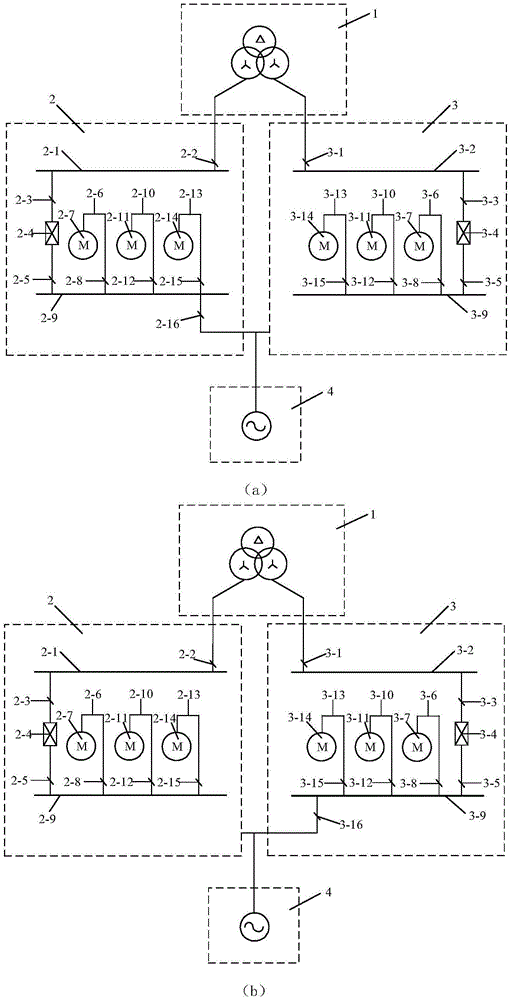

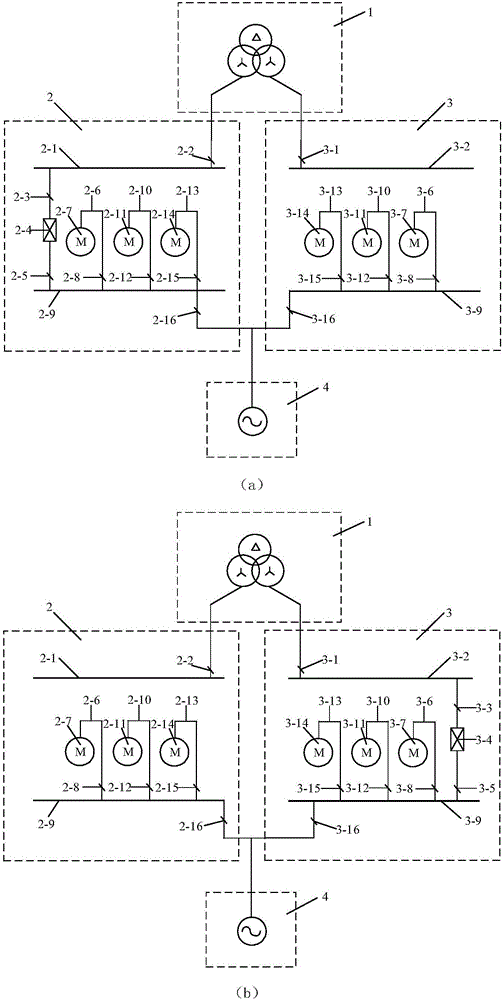

[0036] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0037] like figure 1 As shown in the figure, the present invention is an auxiliary power source system for power plant adjustment, including a high-voltage plant transformer 1, a section A plant auxiliary machine 2, a B section plant auxiliary machine 3, and a unified power source generator 4; wherein , the high-voltage side inlet end of the high-voltage factory transformer 1 is connected with the main wiring of the external thermal power plant, and the two low-voltage side outlet ends are respectively connected with the A-stage auxiliary equipment 2 and the B-section auxiliary equipment 3 through cable lines; The incoming line end of the plant auxiliary machine 2 in section A is connected with the incoming line end of the plant auxiliary machine 3 in section B through a cable line and is connected with the outlet end of the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com