Boiler fly ash remelting chromium slag detoxification system for improving blend ratio of chromium slag and method thereof

A technology for chromium slag and fly ash, which is applied in the system field of detoxification through a boiler fly ash remelting system, can solve the problems of restricting the processing speed of chromium slag, single correspondence, and inflexible operation mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with specific embodiment:

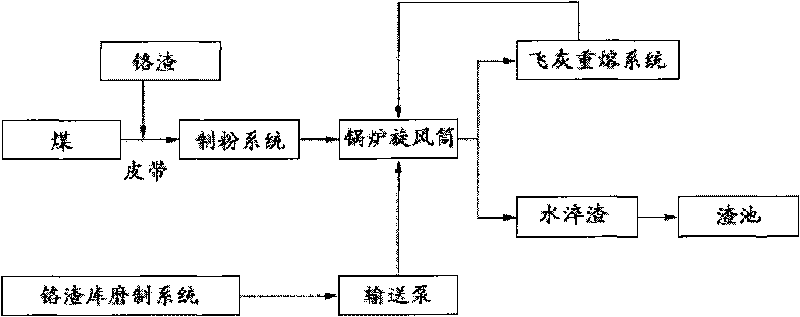

[0020] Such as figure 1 Shown, the technological process of boiler fly ash remelting chromium slag detoxification system of the present invention is as follows:

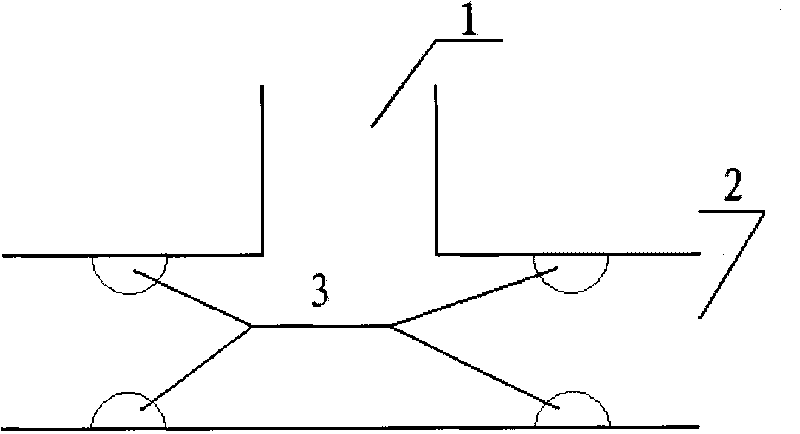

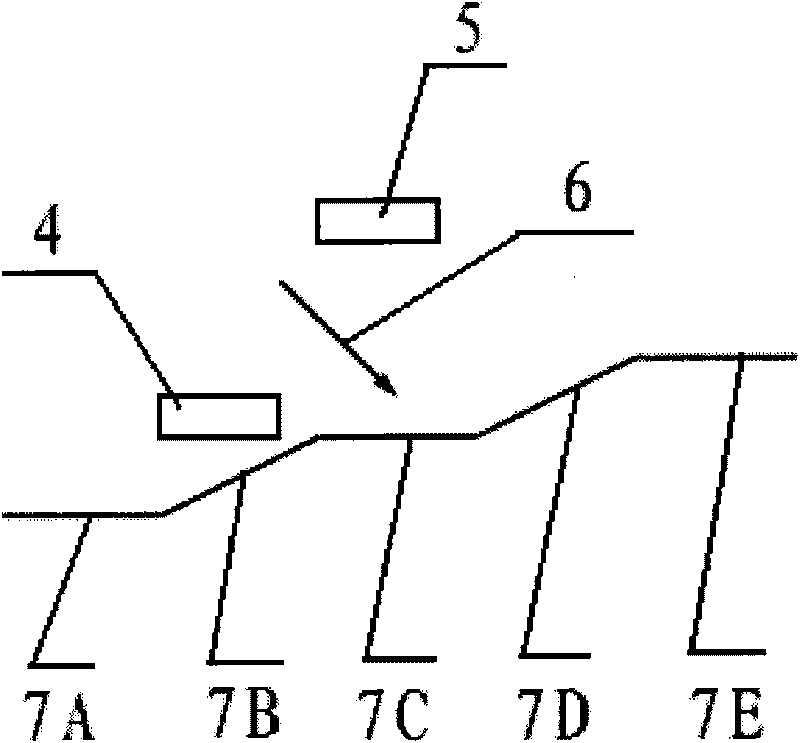

[0021] Coal and chromium slag are sent to the crusher for pulverization and metering, mixed according to the proportion of 15-20%, and then conveyed to the ball mill through the belt to be ground into a fine powder of R90≈20%, and then sprayed into it by air at high speed Combustion in a vertical cyclone furnace for coal-fired liquid slag removal. It is also possible to set up a fan mill in the chromium slag warehouse to grind the chromium slag into 160-mesh fine powder, store it, connect it to the fly ash remelting nozzle of the boiler through a delivery pump and pipeline, and transport it to the boiler with compressed air for combustion and detoxification , when the fly ash remelting of the boiler is completed, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com