Low temperature electric precipitation system in fuel electric plant

A thermal power plant, low and low temperature technology, which is applied in the field of low and low temperature electrostatic precipitator systems in thermal power plants to achieve the effects of saving equipment investment, improving thermal economy, and reducing the power consumption rate of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

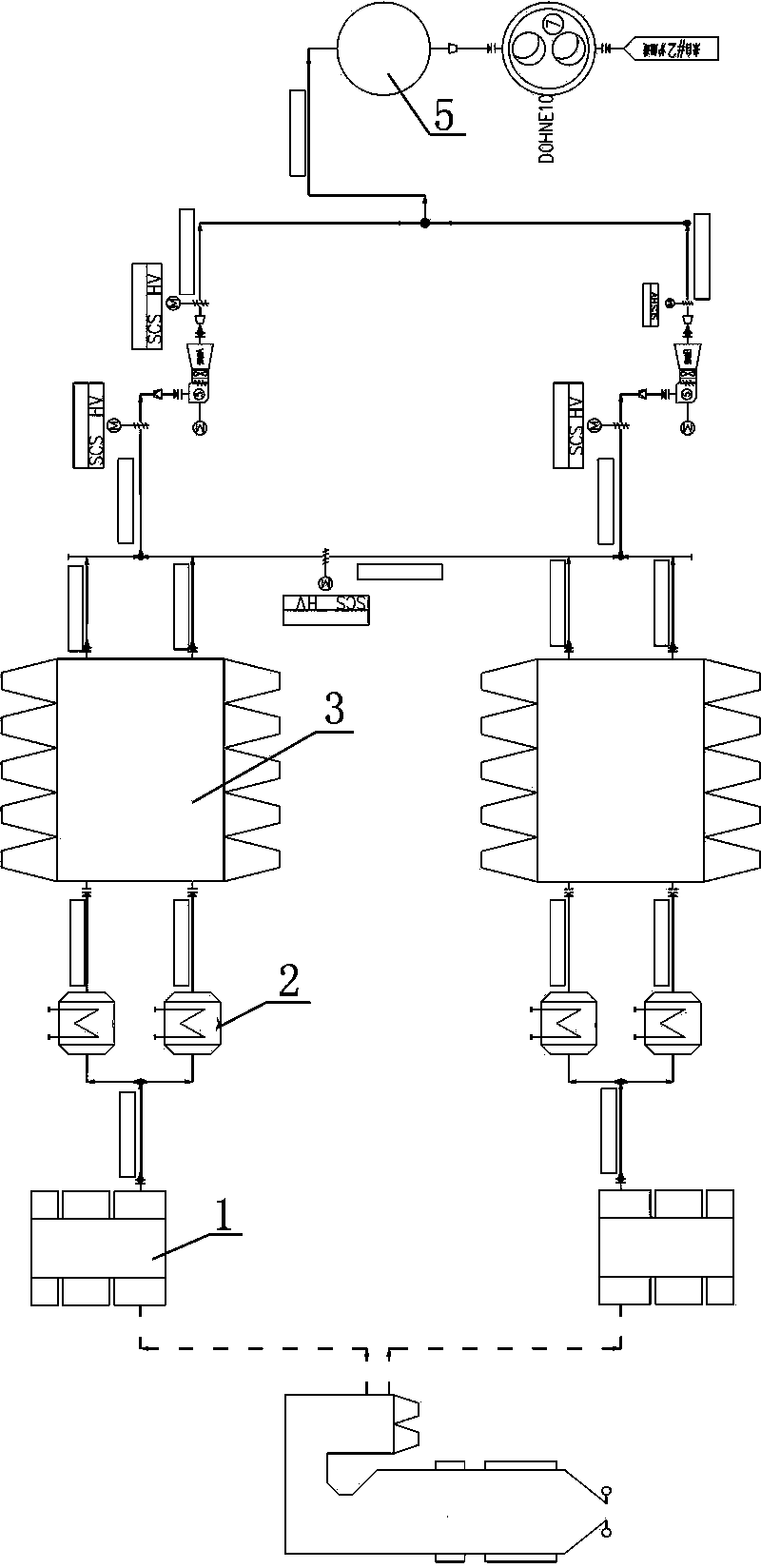

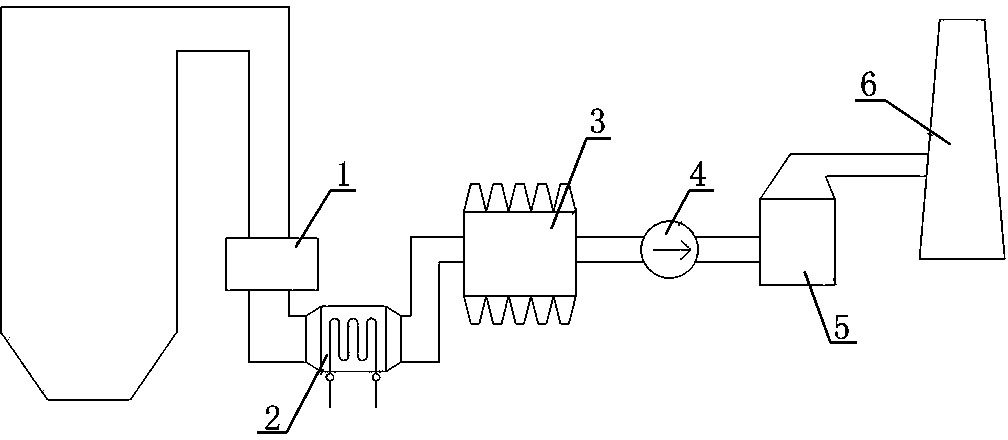

[0020] figure 1 , 2 As shown, the present invention includes a connecting pipe connecting the air preheater 1 and the electrostatic precipitator 3 and a flue gas heat exchanger 2 between the two devices, and the induced draft fan 4 is arranged on the electric precipitator 3 and the desulfurization absorption tower 5 through the connecting pipe Between, the chimney 6 is arranged after the desulfurization absorption tower 5.

[0021] The flue gas temperature at the inlet of the flue gas heat exchanger 2 is 120°C, and the flue gas temperature at the outlet is 90°C, which is lower than the dew point temperature of the flue gas; all the condensed water from the outlet of the 7# low-pressure heater flows to the flue gas heat exchanger 2, and condenses The water is heated from 70°C to 87°C in the flue gas heat exchanger 2 and then returns to the inlet of the 6# low-pressure heater. The heat exchange type of the flue gas heat exchanger 2 can adopt countercurrent heat exchange. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com