A dust-absorbing base and a dust-absorbing sand board using the dust-absorbing base

The technology of bottom plate and sand plate is applied in the field of decoration tools, which can solve the problems of poor working environment of construction personnel and inability to practically solve problems, achieve good market application prospects and development value, facilitate dust collection rate, and improve the effect of working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

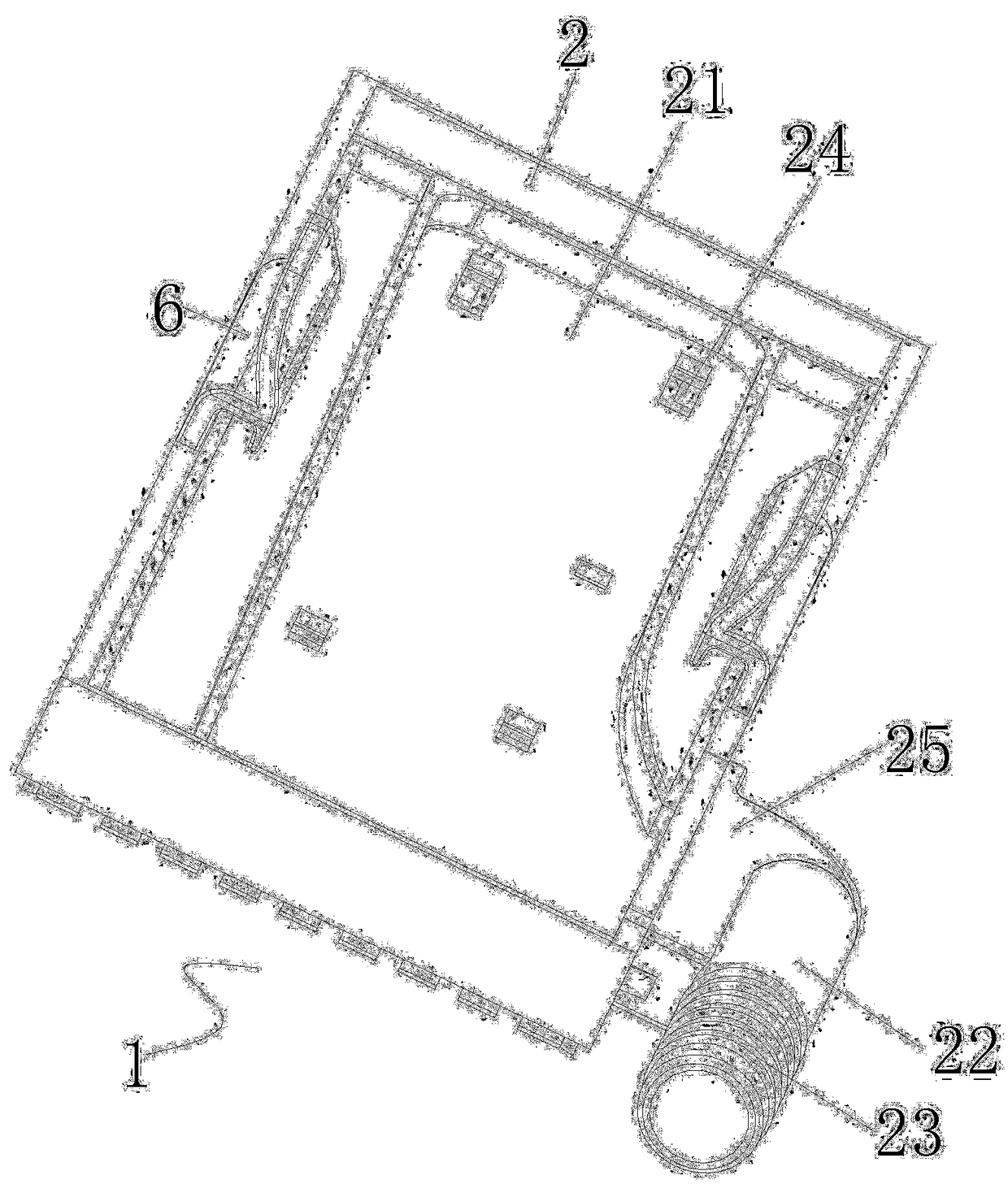

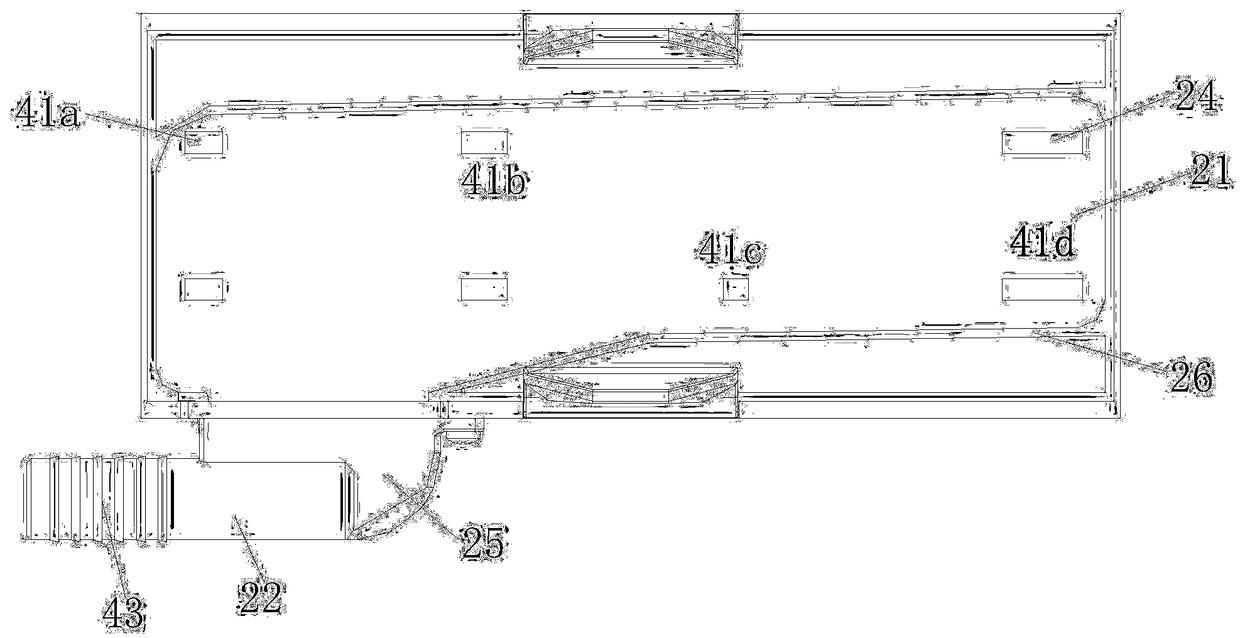

[0029] Such as figure 1 , 2 , 3, and 4, this embodiment discloses a dust-absorbing base, including a ventilation plate 2 and a bottom plate 4 that are fastened up and down. The dust-absorbing base of the present invention is used with a sand board, and the specific shape is based on the sand board Different shapes can be transformed, and when the sand board was square, the ventilation board 2 of the present invention and the base plate 4 were square, and when the sand board was circular, the ventilation board 2 of the present invention and the base board 4 were circular.

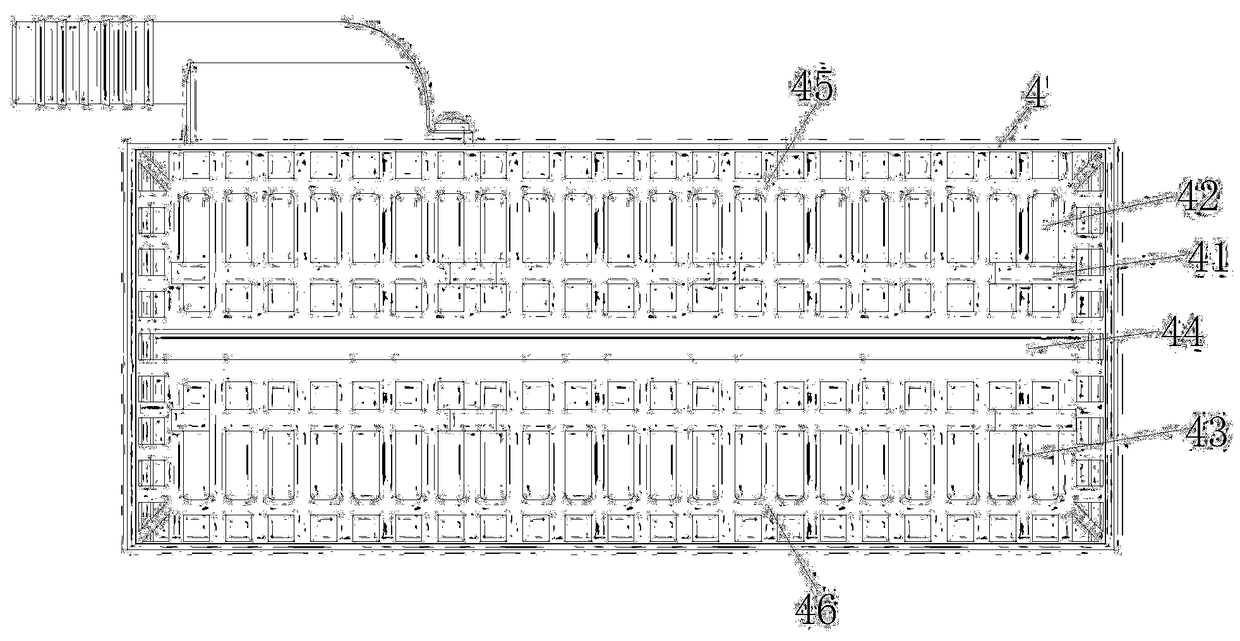

[0030] A plurality of suction holes 41 are arranged through the thickness direction of the bottom plate 4 , and a plurality of shunt ribs 42 arranged in an array are arranged on the bottom panel of the bottom plate 4 . The bottom panel extends vertically downwards, and there is an air guide groove 43 between two of the distribution ribs 42 that conducts the air path to the dust suction hole 41, and a partit...

Embodiment 2

[0046] Such as Figure 5 , 6 As shown in . On the surface panel, the sandpaper is arranged on the bottom panel of the bottom plate 4, and the two ends of the sandpaper are respectively fixed by a pair of clamping mechanisms arranged on the sandboard body 8, and the clamping mechanism includes a spring plate 12, an end There is a cam 16 with clip ears 14 on the top, one end of the spring plate 12 is fixed on the sand board body 8, and the other end is freely arranged, and the wheel shaft of the cam 16 is fixed on the sand board body 8 through the cam seat, forward rotation Or reverse the cam 16 so that its wheel surface loosens or presses the spring plate 12, the end of the sandpaper stretches into the gap between the spring plate 12 and the sand plate body 8, and the wheel of the cam 16 The end of the sandpaper is clamped when the surface presses the elastic plate 12 . It is particularly convenient to install and fix sandpaper based on the above structure.

[0047] The san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com