Matching method of supercritical secondary reheating unit reheater and thermal system

An ultra-supercritical, double reheating technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of increasing the initial investment of power plants and reducing the economic efficiency of power plants, so as to improve thermal economy and reduce plant consumption Electricity, increase the effect of steam extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Ultra-supercritical secondary unit reheating system

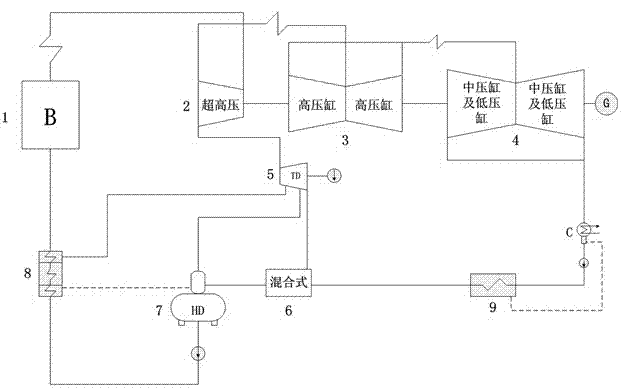

[0019] like figure 1 As shown, the ultra-supercritical secondary unit reheat system of the present invention mainly includes a steam turbine, a boiler (1), a generator, a feedwater pump turbine (5), a high-pressure regenerative heater (8), and a deaerator ( 7), a hybrid heater (6), a low-pressure heater (9), the boiler (1) is an ultra-supercritical DC double reheat boiler, and the steam turbine is a single-shaft steam turbine, including an ultra-high pressure cylinder (2) , high-pressure cylinder (3) and medium-pressure cylinder and low-pressure cylinder (4);

[0020] Among them, the exhaust port of the ultra-high pressure cylinder (2) is connected to the boiler (1) one way, and the other is connected to the feedwater pump turbine (5); the steam extraction port of the feedwater pump turbine (5) is connected to the high pressure regenerative heater (8 ), the other is connected to the deaerator (7), the e...

Embodiment 2

[0024] Example 2: Matching method between reheater and thermal system of ultra-supercritical secondary unit

[0025] In the method of matching the reheater and thermal system of the ultra-supercritical secondary unit, the boiler (1) is an ultra-supercritical once-through secondary reheat boiler, the steam turbine is equipped with an ultra-high pressure cylinder (2), and the exhaust of the ultra-high pressure cylinder (2) There are two steam paths, one path goes to the boiler (1) for reheating once, and the other path supplies steam for the water pump turbine (5); the steam that has been reheated once enters the high-pressure cylinder (3) to do work, and all the exhaust steam from the high-pressure cylinder goes to the boiler ( 1) Secondary reheating, the steam reheated by the boiler (1) goes to the medium-pressure cylinder and low-pressure cylinder in turn to do work; the extraction steam of the feedwater pump turbine (5) is taken from the exhaust steam of the ultra-high pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com