Online pipe anti-blocking method for utility boiler primary air pipe

A technology to prevent power stations and secondary winds. It is applied in the direction of conveying bulk materials, transportation and packaging, and conveyors. It can solve problems such as increasing the output pressure of induced draft fans, increasing the carbon content of fly ash, and prolonging the ignition distance of pulverized coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

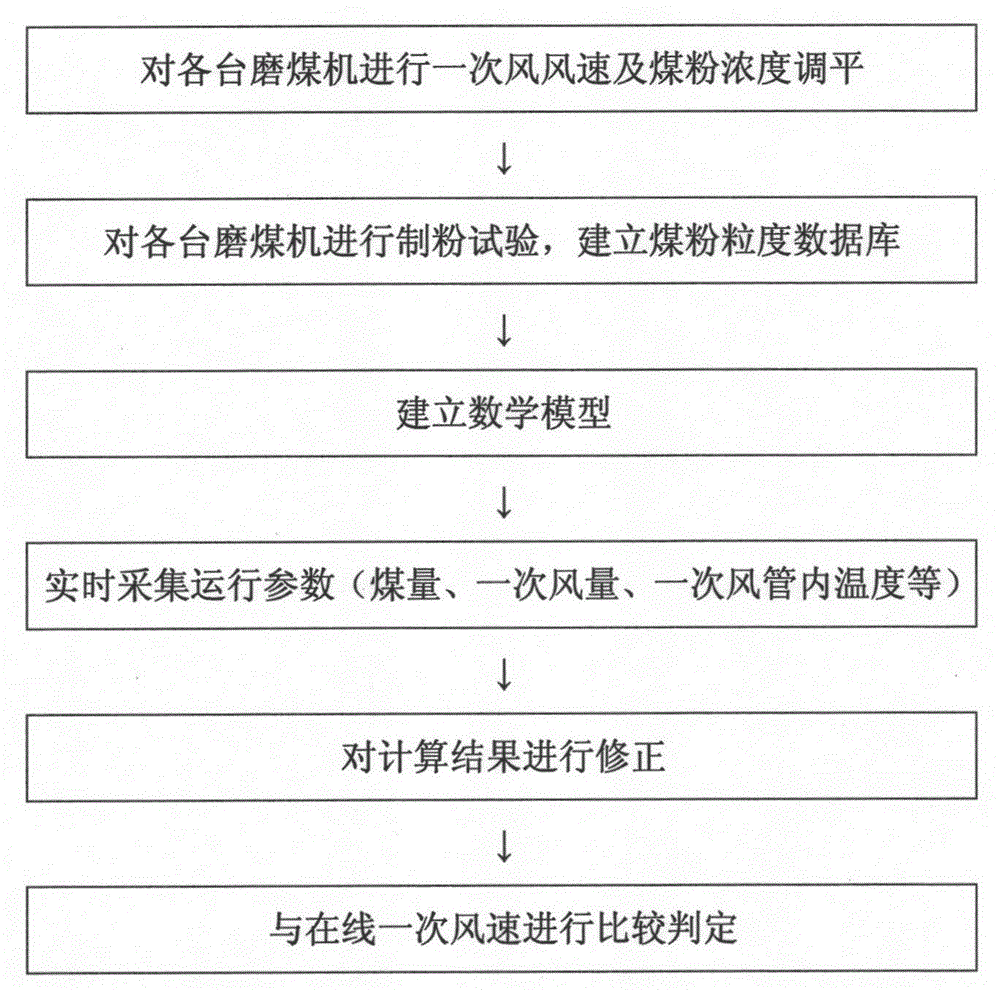

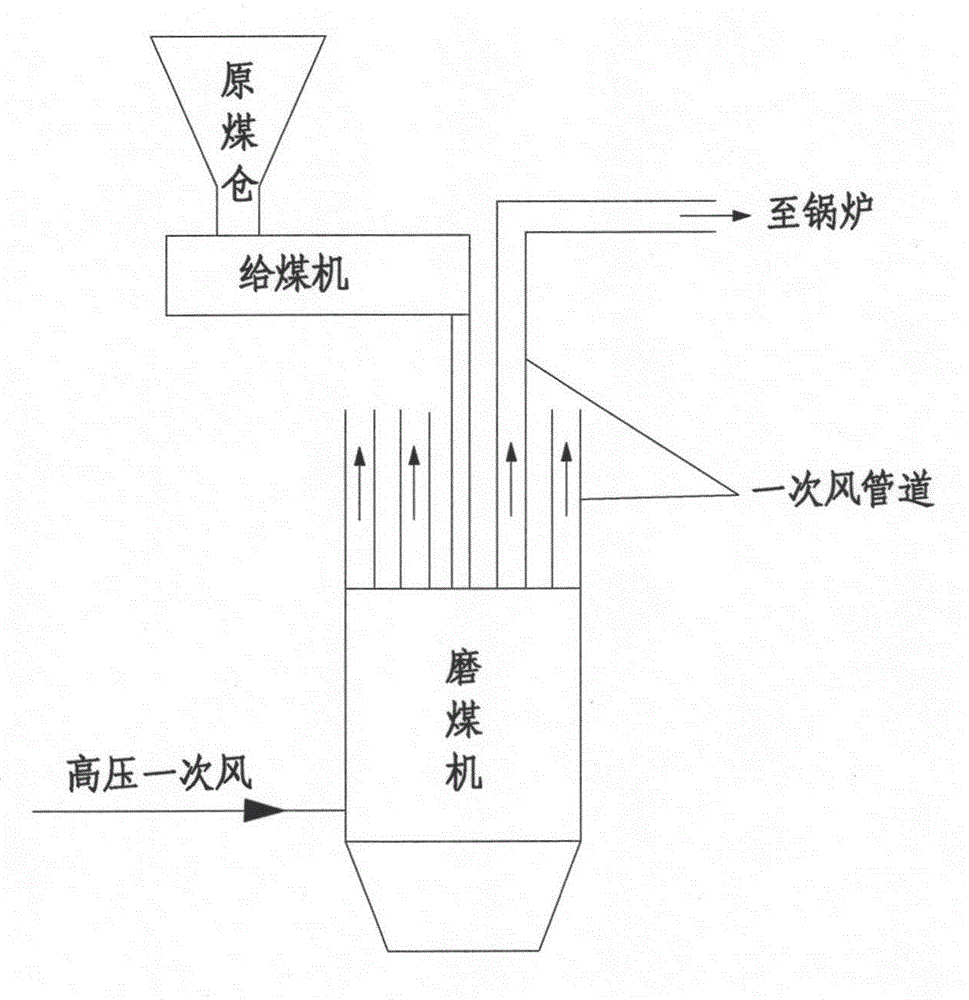

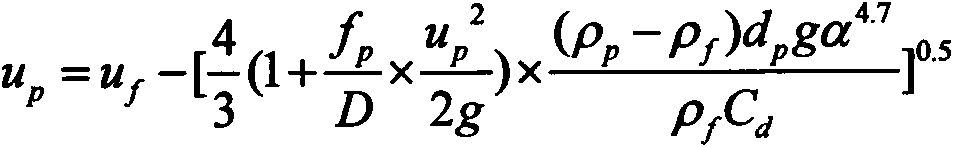

[0039] figure 1 The flow chart of the method for online prevention of primary wind pipe blockage of power plant boilers provided by the present invention. In this embodiment, a 300MW unit in a power plant is selected as a boiler with a four-corner tangential combustion mode, equipped with 5 HP863 medium-speed coal mills, and adopts positive pressure direct blowing type milling system, such as figure 2 shown. A grid-type pulverized coal distributor is installed at the outlet of the coal mill.

[0040] The online method for preventing plugging of a primary air pipe of a utility boiler comprises the following steps:

[0041] Step 1: Four primary air ducts are led out from each pulverizer of the four-corner tangential boiler, and the primary air velocity of these four primary air ducts is adjusted in the cold state. The leveling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com