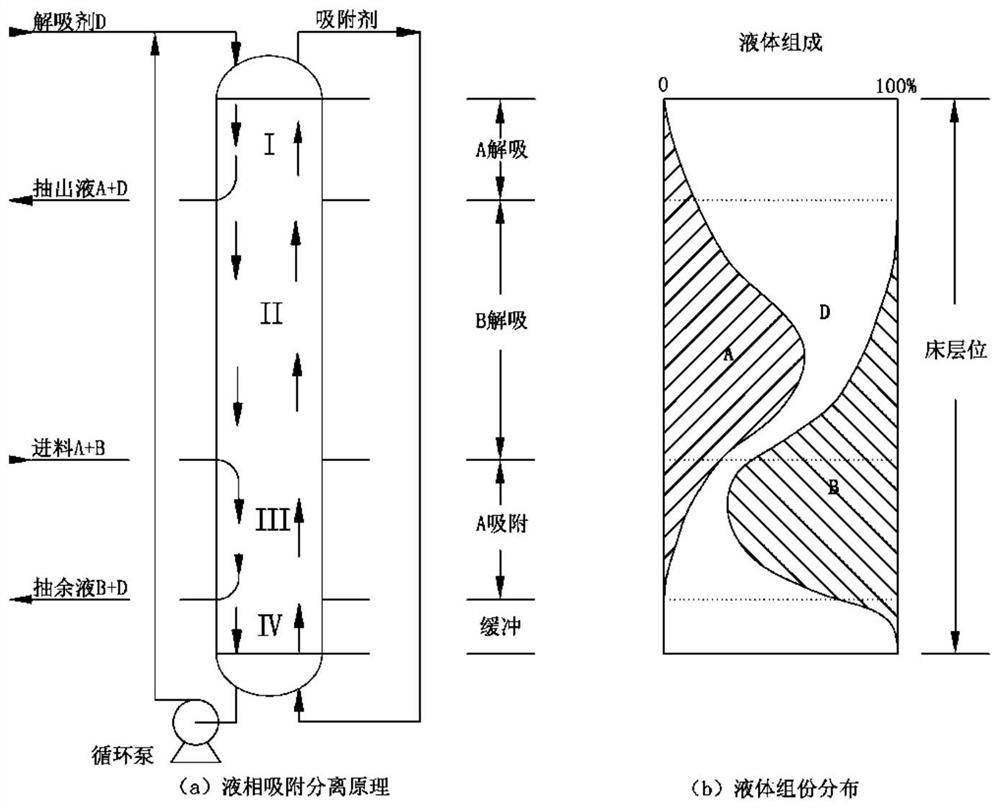

Liquid-phase adsorption separation system

A liquid-phase adsorption and separation system technology, applied in the direction of solid adsorbent liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of large pressure difference of regulating valve, difficult to eliminate stress, and high energy consumption of circulating pump , to eliminate pressure fluctuations, increase adjustment flexibility, and reduce motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

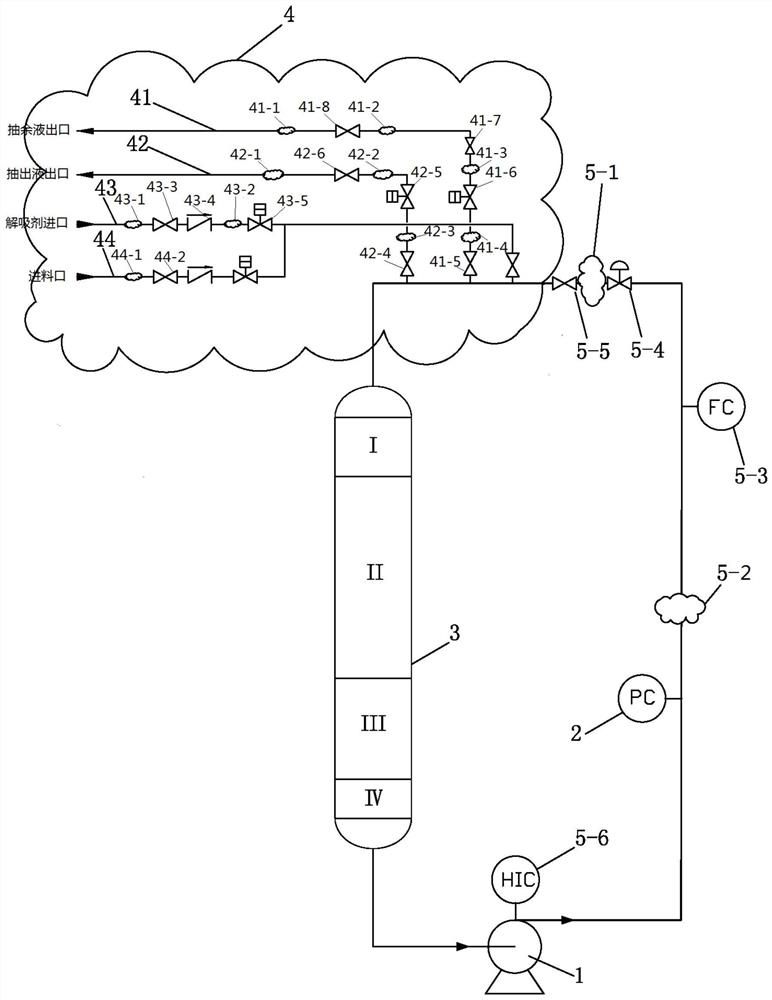

[0036] A liquid phase adsorption separation system, comprising a liquid phase adsorption separation tower 3, a liquid phase adsorption separation tower bed line 4, a pumping circulation pipeline 5, a frequency conversion circulation pump 1 and a pressure controller 2; the liquid phase adsorption separation tower 3 There are several beds, and each bed of the liquid-phase adsorption separation tower 3 is connected to the bottom of the liquid-phase adsorption separation tower 3 through a pumping circulation line 5, which is close to the liquid-phase adsorption separation tower 3 The position at the bottom end is provided with a frequency conversion circulation pump 1, and the pumping circulation pipeline 5 is connected with the bed pipeline 4 of the liquid phase adsorption separation tower. A pumping circulation pipeline damper is provided, and the frequency conversion circulation pump 1 is provided with a circulation pump frequency conversion manual regulator valve 5-6. The bed ...

Embodiment 2

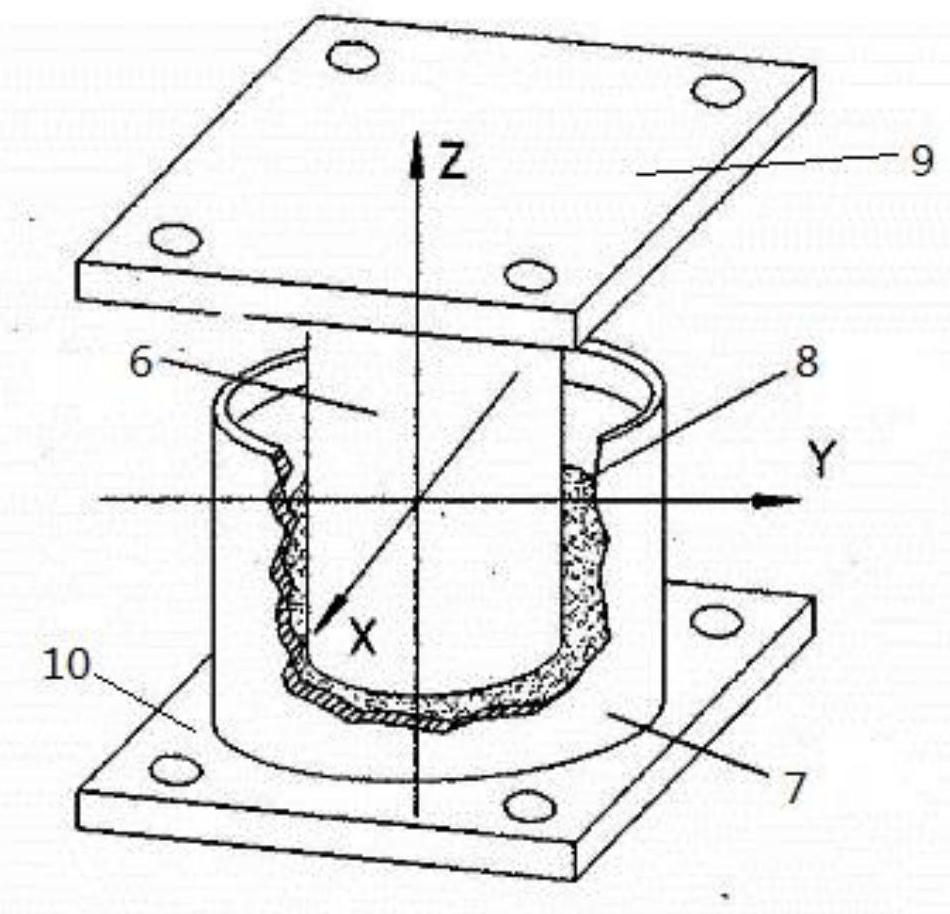

[0038] 1. The structure and shape of the viscous damper (also known as the pipeline damper) adopting pipeline damping in the present invention are as follows: figure 2 shown. The viscous damper adopted in the present invention is a commercially available viscous damper, and the structure has no special design. The viscous damper is composed of a plunger 6, a housing 7, a damping fluid 8, a top plate 9, a bottom plate 10 and a protective cover (wrapping the whole viscous damper to prevent dust and water vapor from entering). Described plunger 6 is connected with top plate 9, and casing 7 is connected with bottom plate 10, and plunger 6 is cylindrical, and casing 7 is hollow cylindrical shape, and the diameter of plunger 6 is less than the internal diameter of casing 7, and plunger 6 is not connected with top plate 9. One end of the connection protrudes into the shell 7 and has a certain gap with the bottom plate 10 , and the damping fluid 8 is filled between the plunger 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com