Hydrogen injection proportional solenoid valve

A proportional solenoid valve and hydrogen supply technology, applied in the direction of lift valve, circuit, slide valve, etc., can solve the problems of easy leakage, poor sealing, complex processing, etc., and achieve the effect of avoiding leakage, reducing outlet pressure and increasing hydrogen flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

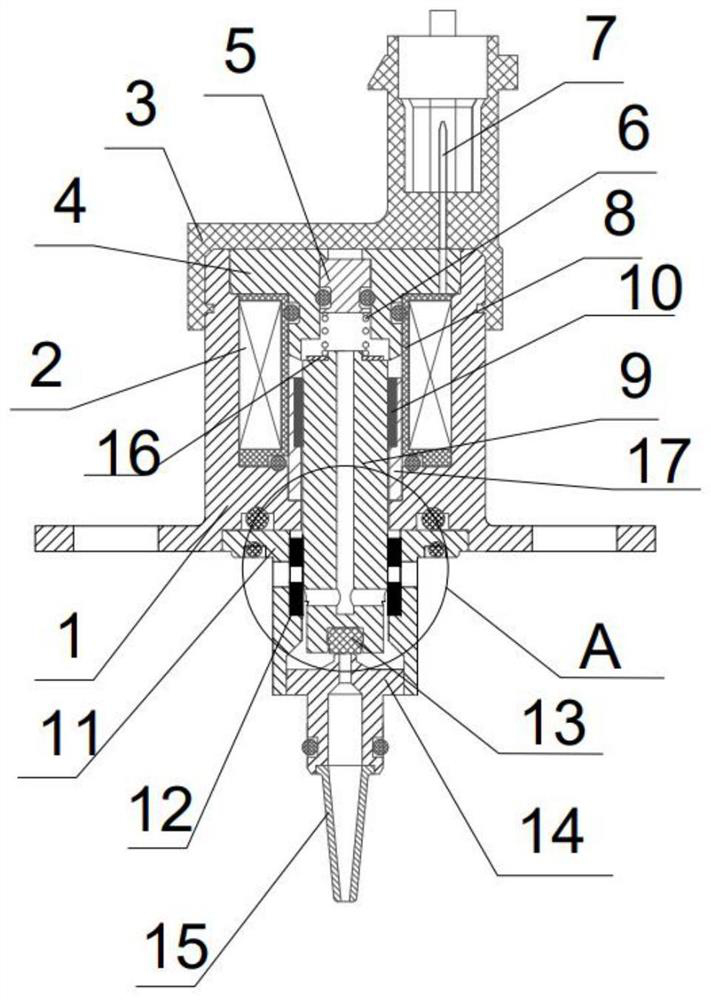

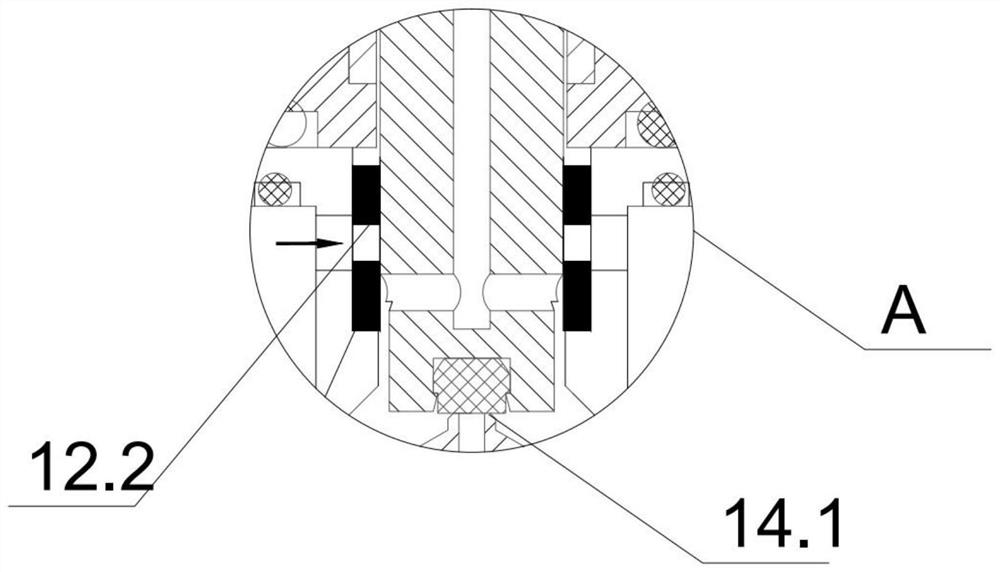

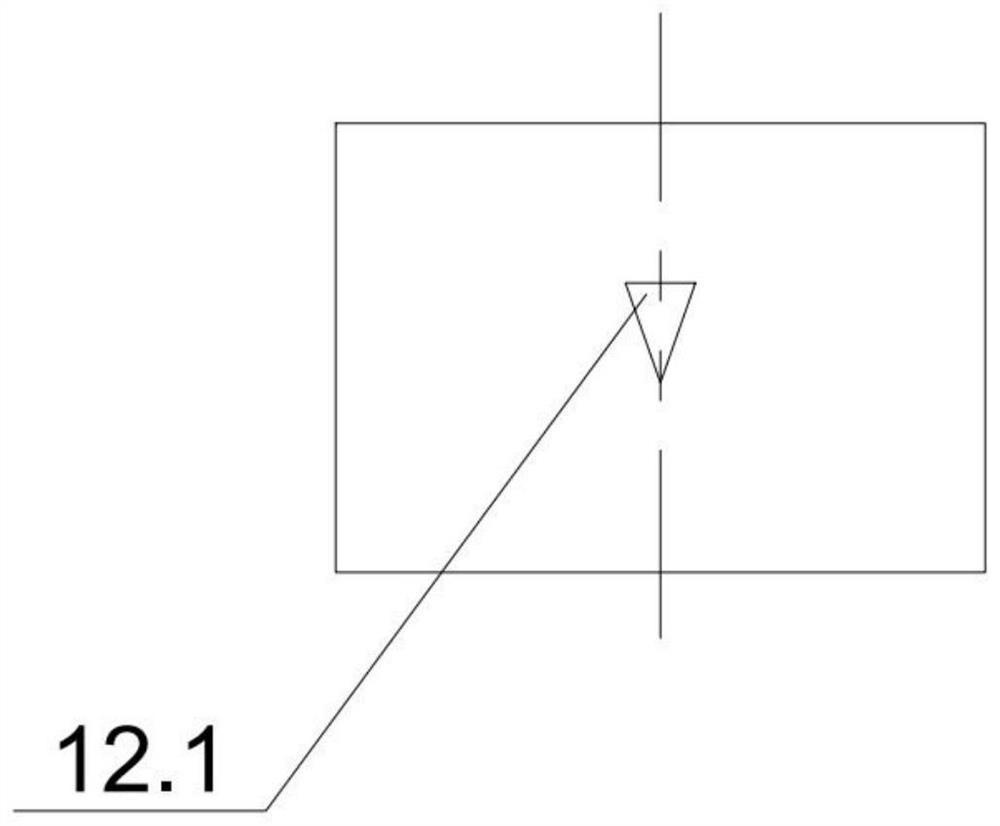

[0028] Specific implementation of the present invention: the hydrogen injection valve is a proportional flow valve, the maximum stroke of the moving iron core 9 is 2mm, the lower part of the housing 1 is press-fitted with the valve seat 11, the upper part of the housing 1 is press-fitted with the pole piece 4, and the lower end surface of the inner hole of the housing 1 Slotted O-ring seal, valve seat 11 is evenly distributed with four circulation holes along the axis, valve seat 11 and sliding bearing 2 12 are press-fitted, sliding bearing 2 12 is evenly distributed with four triangular flow channel holes 12.1 along the axis, The valve seat 11 is slotted for O-rings, the slot inside the pole shoe 4 is press-fitted with the spring seat 5, the head of the pole shoe 4 is a wedge-shaped structure, and there are two round holes on the pole shoe 4 for the pin 7. 4 and the spring seat 5 both have O-ring grooves, one end of the spring 6 is pressed on the spring seat 5, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com